|

Air Driven Pumps and Boosters

Comparison of Pneumatics to

Hydraulics

https://en.wikipedia.org/wiki/Pneumatics#Comparison_to_hydraulics

Both pneumatics and hydraulics are applications of fluid power.

Pneumatics uses an easily compressible gas such as air or a suitable pure

gas—while hydraulics uses relatively incompressible liquid media such as oil.

Most industrial pneumatic applications use pressures of about 80 to 100 pounds per square

inch (550 to 690 kPa).

Hydraulics applications commonly use from 1,000 to 5,000 psi (6.9 to 34.5 MPa),

but specialized applications may exceed 10,000 psi (69 MPa).[citation

needed].

|

|

Advantages of pneumatics |

- Simplicity of design and

control—Machines are easily designed using

standard cylinders and other components, and operate via simple on-off control.

- Reliability

—Pneumatic systems generally have long operating lives and

require little maintenance. Because gas is compressible, equipment is less

subject to shock damage. Gas absorbs excessive force, whereas fluid in

hydraulics directly transfers force. Compressed gas can be stored, so machines

still run for a while if electrical power is lost.

- Safety—There is a very low chance of fire

compared to hydraulic oil. Newer machines are usually overload safe.

|

|

|

Advantages of hydraulics |

- Liquid does not absorb any of the supplied energy.

- Capable of moving much higher loads and providing

much higher forces due to the incompressibility.

- The hydraulic working fluid is basically

incompressible, leading to a minimum of spring action. When hydraulic fluid flow is stopped, the slightest motion

of the load releases the pressure on the load; there is no need to "bleed off"

pressurized air to release the pressure on the load.

- Highly responsive compared to pneumatics.

- Supply more power than pneumatics.

- Can also do many purposes at one time:

lubrication, cooling and power transmission.

|

|

|

|

Leading with Quality, Performance and Cost

Our partners, the

HYDRAULICS

INTERNATIONA(HII), is one top Professional

Hydraulic

Pneumatic Conjugations and Integrations equipment manufacturer and

integrated solution supplier.

HII has over 30 years history of cutting edge

support equipment ingenuity and new product technology innovation in three main

business units:

- Defense/Aviation/Commercial Ground and

Engineering Support Equipment Systems.

- Gas and Liquid

Extraction Pumps/Pneumatic driven liquid pump/Gas

booster/Amplifier systems.

- Flow metering/analyzing/totalizing

systems.

HII is one of the few companies having total self sufficiency in design and

manufacture of the systems and components required for its’ business units.

Ongoing research and development in all areas has improved operation, quality,

and functionality of the business unit products and systems.

|

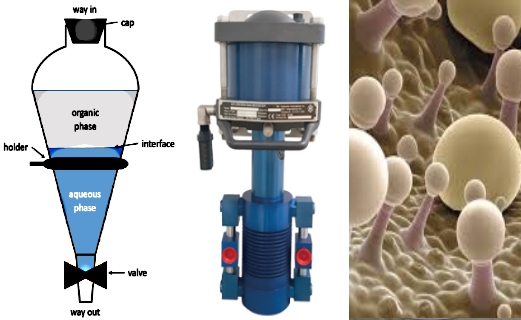

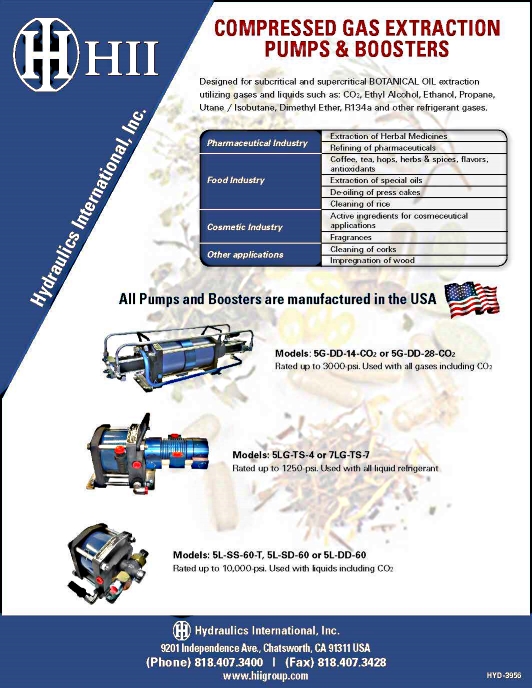

Compressed Gas and Liquid Extraction

Pumps & Boosters

Designed for subcritical and

supercritical BOTANICAL OIL extraction utilizing gases and liquids such as :

CO2, Ethyl Alcohol, Ethanol, Propane,

Butane / Iso-butane, Dimethyl Ether, R134a and other

refrigerant gases.

|

Pharmaceutical Industrial |

Extraction of

Herbal Medicines

|

Refining of pharmaceuticals

|

|

Food Industry |

Coffee, tea, hops, herbs & spices,

flavors, antioxidants

|

Extraction of special oils

|

|

|

De-oiling of pressed cakes

|

Cleaning of

rice

|

|

Cosmetic Industry |

Active ingredients for cosmeceutical

applications

|

Fragrances

|

|

Other applications |

Cleaning of

corks

|

Impregnation of wood

|

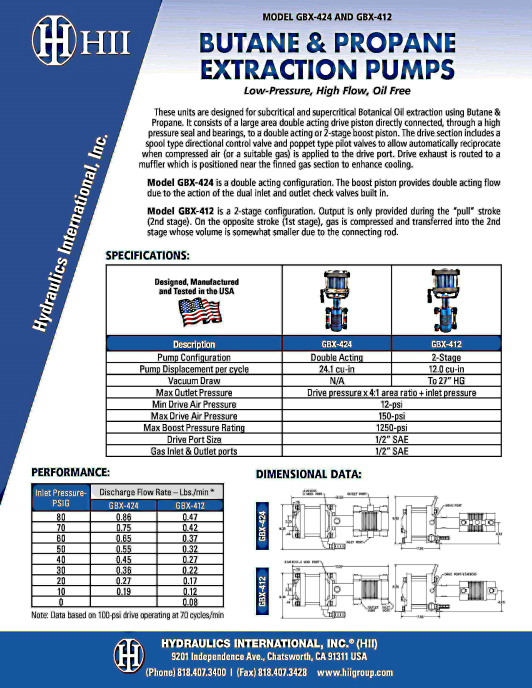

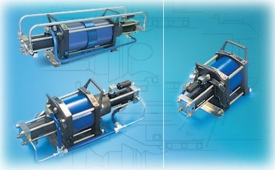

BUTANE & PROPANE EXTRACTION PUMPS

Low-Pressure, High Flow, Oil Free

These units are designed for subcritical and

supercritical Botanical Oil extraction using Butane & Propane. It consists of a

large area double acting drive piston directly connected, through a high

pressure seal and bearings, to a double acting or 2-stage boost piston. The

drive section includes a spool type directional control valve and poppet type

pilot valves to allow automatically reciprocate when compressed air (or a

suitable gas) is applied to the drive port. Drive exhaust is routed to a muffler

which is positioned near the finned gas section to enhance cooling.

|

![]()

|

|

|

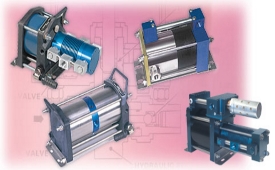

Air Driven Liquid Pumps

Why use Air Driven Liquid Pumps

•

Hydraulic pressure is held without energy consumption.

• Explosion proof ... requires no electrical power or connections.

• Intrinsically safe.

• Compact, lightweight and weatherproof.

• Easy to adapt automatic controls.

• Contamination tolerant.

• Outlet stall pressure pre-determined by the air drive regulator.

• High pressure capability - up to 80,000 psi.

• Ideal for stop-start applications under full load.

• Easy to install and operate.

Typical applications

• Hydrostatic testing

• Clamping-Pressing-Releasing

• Valve actuation

• Portable hydraulic tools

|

|

Air Driven Boosters

Features:

• Separation between drive and gas section uses three dynamic seals with dual

vents.

• Air drive line lubrication not required.

• Rugged soft-seat, high-flow check valves in gas section(s).

• Only hydrocarbon-free stainless steel, bronze, PTFE and Viton gas section

internal parts exposed to gas flow.

• Heat of compression reduced for long seal life because cold exhaust air

surrounds gas barrel(s) inside cooling sleeve(s) (see Figure 1, Item 4 above).

• Standard trim is weatherproof and suitable for offshore service.

Typical Applications:

• Pressure Testing Piping and Hardware for Leakage: e.g., oil field, refinery,

aircraft, automotive, instrumentation using gases.

• Gas Injection: chemical process, plastic forming.

• Gas Scavenging: collecting costly gas in partially used cylinders and

transferring it into high pressure receiver(s) for further use.

• Life Support Gas Transfer and Charging: e.g., oxygen, helium, breathing air,

diving, fire fighting/hazmat, aircrew.

• Compressed Natural Gas (CNG) Boosting for vehicle refueling stations.

|

|

Air Driven Air Pressure

Amplifiers

Features:

• Compact: installs off the floor, out of the way, in any position.

• 2 connections: plant air in, amplified air out. (Pilot air connection is

optional for start-stop control with a PCV valve or solenoid valve and pressure

switch.)

• Can replace a dedicated air compressor: 10 HP size in a typical large plant

spot requirement for 100 PSI when only 80 PSI is available. (Model 5A-DS-2)

• Replace bottled nitrogen: up to 700 PSI (48.3 BAR) for air testing, lab or

production. (Model 5A-DS-5 & 7A-DS-8)

Typical applications:

• Valve actuators

• Air starters

• Bin vibrators

• Pneumatic drill motors

• Air clamps

• Air brakes

• Off road tires

|

|

Electric Driven Boosters

Series 2G Electric Driven Booster package is ideal for

filling or topping off low-pressure and high-pressure bottles. Its two-stage and

double acting design uses NO Belts or Pulleys, making it the quietest Electric

Driven Booster in its class; only 60 dBA. Air cooled with its integrated cooling

fan reducing the heat of compression for long seal life.

OXYGEN GAS BOOSTER

AUTHORIZED FOR NAVY USE (ANU)

50% INCREASE IN BOTTLE FILLS & ELIMINATES CASCADING

STANDARD EQUIPMENT:

• Automatic stop & restart high

pressure limit control FACTORY pre-set to 3000-psig (adjustable)• Automatic stop & restart low pressure limit

control FACTORY pre-set to 250-psig (adjustable)• Manual start & stop switch

• Safety relief valve set @ 3200-psi

• Gas inlet pressure reducing

regulator to control safe fill rates

• Bypass line with on/off valve

(needle type)

• O2 cleaned to MIL-STD 1330D with

certification

• Double acting configuration

• Inlet & outlet pressure gauges

(calibrated with certs)

• Hour meter with 6-digits

• Sealed ball bearings

• Inlet & outlet 5-micron filters

• Outlet and bleed valves (needle

type)

• Air cooled

OPTIONAL EQUIPMENT:

• Dual outlet pressure control

• Inlet & outlet hose kits

• Remote start/stop switch

with 6-foot cord

• Four (4) port outlet manifold

• 2-stage configurations

• Gas inlet & outlet Quick

Couplings (QD)

|

|

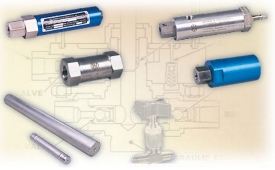

High Pressure Components

PRESSURE

RELIEF VALVES

PILOT CUTOFF VALVES, High Pressure, Low Flow

These valves are direct operated, differential poppet,

dry spring chamber design. All ports can accept full working pressure permitting

their use also as a sequence valve or back pressure

controller regulator (BPR). Wetted alloys are stainless

steel. Dynamic seals are UHMWPE. Static seals

are Buna. Optional: Viton add-V. EPR add-E. Wrench flats

are standard on adjusting screws.*

PILOT CUTOFF VALVES

Sense Liquid or Gas Pressures. Provide Air Signal.

These valves perform a function similar to a pressure

switch. The sensing piston or plunger movement is spring or air adjusted. When

the sensed pressure is reached, a small, integral air valve shifts position

cutting off, or providing, a pilot air signal. Useful for

start/stop control of various pneumatically piloted

devices such as HII pumps, valves and boosters. Maximum

air valve pressure is 120 PSI. Sensing section alloys are stainless steel. Buna

static seal standard, optional: Viton add-V, EPR add -E. (e.g. PCV-E002E)

UNLOADING VALVES

Normally Open, Normally Closed, Air Pilot Actuated.

These valves open or close high pressure oil or plain

water back to tank or to another line or high pressure gas to another line. High

pressure section alloys are stainless steel with stainless steel ball or poppet

design.

INLINE CHECK VALVES, 316 STAINLESS STEEL BODIES

High Pressure. These valves are 316 S.S. ball type and

soft seat (PTFE ring) in

the 1/4 NPT, 1/2 NPT, 3/4 NPT, and 1 NPT sizes; Brass

poppet on S.S. seat in the

2 NPT size. Control springs hold approximately 3 PSI.

Optional higher pressure

springs are available in the 2” NPT unit only.

AIR OPERATED ON / OFF VALVE

This air operated valve opens and closes high pressure

liquid or gas connection. Balanced poppet, piston actuated, normally open,

bubble tight design assures high reliability. Minimum actuation is a 30-PSI and

Maximum is a 150-PSI. Constructed of 316-SS with a Cv = 0.75

INTENSIFIER ASSEMBLY 10:1 AREA RATIO

Model IA100K3 is rated to 100,000 PSI output with a

displacement of 3 cu. in./cycle. It can be used to

intensify any liquid or gas compatible with 15-5 PH SS,

BUNA-N and polyurethane. Minimum inlet pressures are 1500 PSI liquid; 5000 PSI

gas.

The drive section consumes approx. 34 cu. in./cycle and

can accept plain water or petroleum based

hydraulic oil to 10,000PSI. Cycle rate should be limited

to 2 cpm depending on the application.

GAS RECEIVERS

High Pressure. These units are normally used at the

outlet of an HII Gas Booster

or system to store a volume of gas for smooth,

intermittent release through a

pressure reducing valve.

|

|

Package Systems

Air Driven Gas Boosters

Low Pressure, High Flow, Oil-Free

For Use With:

Liquified gases at ambient temperature(both phases)

Vaporizers off cryogenic tanks

Instrument air (or plant air)

Air Driven Standard System

Packages

Standard Liquid Pump Packages

Standard Gas Booster Packages

Standard Air Pressure Amplifier Packages

Custom Units

Gas Booster Package Systems

Sport Diving

Fire Departments

Paintball

GENERAL AVIATION

High-Pressure Breathing Air

Systems

For Municipal or Industrial Fire Departments that operate multi-stage

mechanical air compressors with purification and storage cylinders

|

|

Applications for HII Products |

|

|

Automotive/Forklifts

•

Mechanical Press Overload Systems in Automotive

Body Plants

•

QDC (Quick Die Change) Clamping systems

•

Testing of Fuel Injectors

•

CNG Natural Gas Refueling systems

•

Hydrogen Gas Refueling systems

•

Airbag Inflation Charging Systems

•

Hose and Radiator Pressure Testing

•

Air Conditioning Charging and Leak Detection

•

Brake System Testing

•

LPG Recovery and Charging

Airline & Aerospace

•

Oxygen Life Support Charging

•

Escape Chute Charging –Co2 Charging

•

Aircraft Jacking

•

Helium Leak Pressure Testing

•

Missile Test Systems

•

Fire Protection

•

Pressure Testing of Hydraulic systems - Skydrol

•

Gas charging for aircraft tire inflation

•

Accumulator Charging on Landing Gear, (suspension)

Cannabis

•

Supercritical and subcritical Botanical oil

extraction

•

CO2 gas & liquid extraction

Defense - Air

•

Operation of Aircraft Jacks

•

Aircraft Seat Ejection – CO2

cylinder charging

•

Charging of Oxygen Life Support Cylinders

•

Charging of Helicopter Pop Floats

•

Fire Prevention Systems

Defense - Land

•

Gun Recoil – Tanks

•

Gas Suspension – Tanks

•

Tank Jacking Systems

•

Missile Launch Leveling

•

Armaments Manufacture – Testing

•

Argon Cooling on Infrared Systems – Missiles,

Night Sights etc

Defense - Sea

•

Life Support Cylinder Charging

•

Gun Recoil

•

Gun Turret Leveling

•

Engine Bolt Tensioning

•

Boiler Testing

Electronics & Computer Industry

•

Wafer Washing

•

Chip Dicing and Sawing

•

Gas Purging

Fire, Health & Safety

•

Stretch Testing & Charging Fire Extinguisher

Cylinders

•

Breathing Air Cylinder Charging

•

Rescue Tools - Operation of Jaws of Life

•

Oxygen Generation Systems – PSA Systems for Remote

Field Hospitals (MASH)

General Manufacturing

•

Pressure Testing of Valves, Hoses, Pipes, Gauges,

Pressure Vessels etc

•

Water-Jet Cutting and Blasting

•

Autofrettage of High Pressure Components

•

Gas Cylinder Filling and Charging

•

Pressure Gauge Calibration

•

Operating Hydraulic Jacks

•

Tire Curing Presses

•

Filter Presses

•

Accumulator Charging

•

Powering Crimping and Riveting Tools

•

Bolt Tensioning

•

Wire Forming

•

Isostatic Presses

Laboratory, University & Research

•

Liquid CO2 Chromatography

•

Supercritical Extraction

•

Homogenizing

•

Geological Testing

Machine Tool

•

Roller Tensioning

•

Hydraulic and Pneumatic actuation of cylinders

•

Clamping

•

Lube and Coolant spraying

•

Machine Tool Flushing

•

Gun drilling – Machining Centers

•

Machine Tool Counter Balance accumulator charging

•

QDC Clamping

•

Laser Cutting

Mining & Tunneling

•

Setting of Hydraulic Mine Props

•

Drilling Dust Suppression

•

Rock Bursting Tools

•

Fire Prevention

•

Testing of Roof Support Systems

•

Oxygen Charging of Life Support Bottles

•

Tunnel Shield Operation

Oil & Gas

•

Wellhead Control Panels

•

Chemical Injection

•

Blowout Preventers

•

Wire Line Lubrication

•

Pressure Testing of Valves, pipelines, hoses,

cylinders, accumulators, pressure vessels and components

•

Valve Actuation

•

Subsurface Safety Valve Control

•

Diesel Engine Air Start Systems

Paintball

•

CO2 filling paintball bottles

•

Air or Nitrogen filling bottles to 5500 psi

Plastics

•

Gas Assisted Injection Molding

•

P.E.T Blow Molding

•

Injection of Blowing Agents

•

Air Sleeves – Plastic Printing

Power & Energy

•

Valve Actuation

•

Nitrogen and SF6 Charging and Recovery Systems –

Circuit Breakers

•

Boiler and Heat Exchange Pressure Testing

•

Heat Exchanger Tube Swaging systems

•

Boiler Descaling

•

Live Wire Crimping tools

Railroad

•

Hub Pulling – Bearing Removal

•

Bolt Tensioning

•

Wheel Lubrication

•

Air Conditioning Testing and CFC Recovery

•

Ballast Dump Carts

•

Engine Air star-up systems

Recreational Sports

•

Filling and Charging Scuba Dive Bottles

•

Oxygen and Nitrox Dive Cylinder filling and

charging

•

Stretch Testing Cylinders

•

Paint Gun Cylinder charging

• Charging Nitrous Oxide Bottles

|

|

|

|