Enzymaster R&D Collaboration Services

Enzyme

screening / Enzyme directed evolution /

Enzyme production by fermentation / Enzymatic process optimizing & up-scaling

More than

one hundred years ago, biocatalysis was employed to do chemical transformations

on non-natural man-made organic compounds, with the last 30 years seeing a

substantial increase in the application of biocatalysis to produce fine

chemicals, especially for the pharmaceutical industry.

Since almost all enzymes are made from L-amino acids, enzymes are chiral

catalysts. As a consequence, any type of chirality present in the substrate

molecule is "recognized" upon the formation of the enzyme-substrate complex,

and

both enantiomers of a racemic substrate may react at different rates.

Enzymes display

major types of selectivities:

-

Chemoselectivity

-

Regioselectivity

-

Diastereoselectivity

-

Enantioselectivity

These are the major reasons why synthetic chemists have

become interested in biocatalysis.

This interest in turn is mainly due to the

need to synthesise enantiopure compounds as chiral building blocks for

Pharmaceutical drugs and agrochemicals.

Other important advantages :

Environmentally acceptable: being completely degraded in the environment.

Minimizes side-reactions:

The enzymes act under mild conditions, which

minimizes problems of undesired side-reactions such as decomposition,

isomerization, racemization and rearrangement, which often plague traditional

methodology.

Very high stability and re-usability: Immobilized enzymes

demonstrate very high stability and re-usability and can be used to conduct

reactions in continuous mode in microreactors.

https://en.wikipedia.org/wiki/Biocatalysis

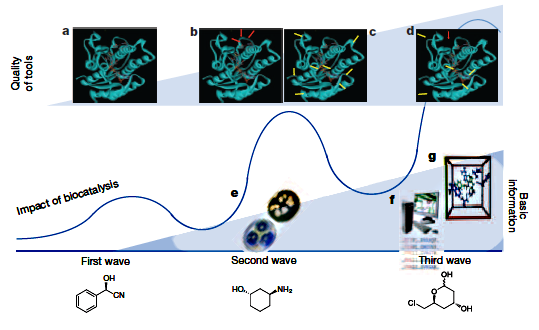

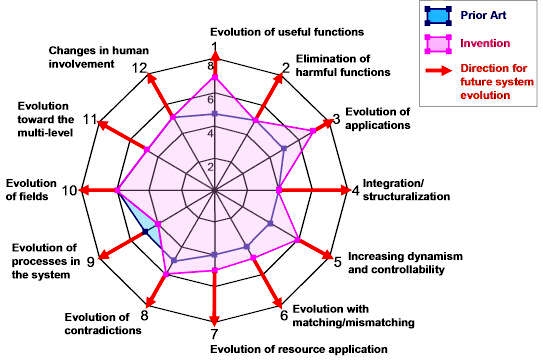

Engineering The Thirdwave of Biocatalysis

http://www.biology.uoc.gr/courses/BIO113_Enzimiki_biotexnologia/images/documents/5.pdf

https://www.ncbi.nlm.nih.gov/pubmed/22575958

The third, and present, wave of

biocatalysis started with the work of Pim Stemmer and Frances Arnold in the mid

and late 1990s. They pioneered molecular biology methods that rapidly and

extensively modify biocatalysts via an in vitro version of Darwinian evolution.

The methods are now commonly called

Directed Evolution,........

Key advances in

advanced protein engineering, gene synthesis, sequence analysis, bioinformatics

tools and computer modelling are at the base of tremendous progress in tailoring

biocatalysts by protein engineering and design, and the ability to reorganize

enzymes into new biosynthetic pathways.

As a result of the advances made during the present wave of biocatalysis,

remarkable new capabilities can now be engineered into enzymes.

Remarkable new

capabilities:

-

Ability to accept previously inert substrates.

-

Change the nature of formed product.

-

Can remain stable at 60C in

solutions containing organic solvents.

-

Can accept new substrates

-

Can catalyse new non-natural reactions.

-

Years work may now take only a few months.

Biocatalysis: Successfully Crossing Boundaries:

“ … Today, enzymes can easily be

engineered for new reactions and to match process demands …”

-

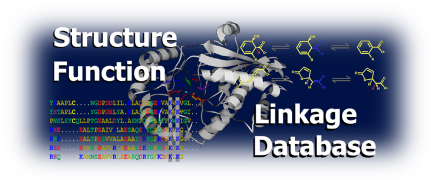

Sequence Databases Foster the

Discovery of Novel Enzymes

-

Computational Tools Facilitate

Enzyme Design

-

Combining Chemo- and Biocatalysis

-

Multistep Biocatalysis or

Metabolic Engineering?

-

New Emerging Chemistry

http://www.chemistryviews.org/details/ezine/8642801/Biocatalysis_Successfully_Crossing_Boundaries.html

http://onlinelibrary.wiley.com/doi/10.1002/anie.201510042/pdf

International Team for Substantial Service,

Supports and Cooperations :

Our team

partners, Enzymaster is a Chinese-multinational Joint company in the high-tech

hubs in China's coastal areas. Having established close collaboration with

numerous domestic companies, we specialised on providing Enzyme Catalysis

Solutions to the pharmaceutical and fine chemical industries.

Our collaborative working includes development of new Enzyme-Catalysis

technology for various high value chiral intermediates, that also facilitate the

transformation of the pharmaceutical and fine chemical manufacturing processes

towards environmentally friendly and cost effective processes.

http://www.enzymaster.com/en/index.asp

http://www.enzymaster.com/index.asp

http://www.chromnet.net/

Multinational and Multidisciplinary Team

The team members of Enzymaster have multinational

origins, such as Germany, Singapore, Malaysia, Australia and China.

We work closely as a multidisciplinary team by combining respective expertise in

various scientific aspects.

|

Dr. David Rozzell

Joined Provivi in August 2015 as Sr VP to head the pharmaceutical division of

the company. Dr. Rozzell has more than 25 years of experience in the

biotechnology industry developing and building innovative companies. He is the

inventor on 24 issued US patents and various pending patent applications. Prior

to joining Provivi Dr. Rozzell created Sustainable Chemistry Solutions, Inc. as

a consultancy and provider of information products to the enzyme industry.

Previously, he was the Founder of BioCatalytics, Inc., a pioneering developer of

enzymes and biocatalysis technology that was acquired by Codexis, Inc. in 2007.

Dr. Rozzell received a PhD in Chemistry from Harvard University and a BS in

Chemistry from the University of Virginia.

He publishes the Enzyme Industry Newsletter, along with two comprehensive

industry guides: The Enzyme Company Guide and The Biocatalysis Company Guide.

site:

http://www.bio-catalyst.com |

Prof. Dr. Christian

Wandrey

http://www.fz-juelich.de/SharedDocs/Personen/IBG/IBG-1/EN/Research_groups/general/wandrey.html?nn=547728

Former Head of Institute of Biotechnology 2 Christian Wandrey was Professor of Biotechnology at the University

of Bonn and head of the Institute of Biotechnology 2 at Forschungszentrum Jülich

from ..... Professor Wandrey's special research interest was bioprocess

development with main focuses in enzyme technology and fermentation technology.

More than 330 scientific publications, about 100 patents and patent

applications, and over 400 seminars present his scientific work. He is

co-initiator of 4 start-up companies, co-editor of 2 books, and member of the

editorial boards of various scientific journals. |

|

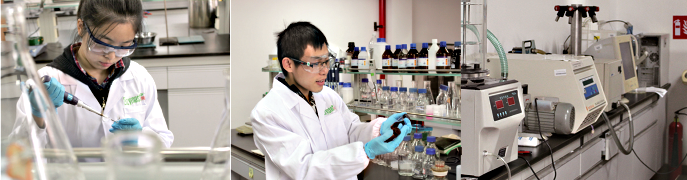

Leading Enzyme Directed Evolution Technology

The platform technology of Enzymaster is on par with the state-of-the-art around

the globe, with strong capability in molecular biology and high throughput

biochemistry.

Independent R&D

We have a strong focus on R&D helding ourselves to high professional

conducts,and take pride to be able to independently create high value, novel

Intellectual Property in-house.

Technology Commercialization

We are the first commercial entity in Chinese area that focuses on employment of

enzyme directed evolution technology for commercial scale production, with

reliable and capable R&D partnership for our collaborators.

Collaborative Projects

Enzyme Screening

We have a wide variety of enzyme panel, such as ketoreductases, transaminases,

hydrolases, and oxygenases. The collaborator shall provide the related material

for the screening (such as substrate, product, analytical methods, and HPLC

columns), and we shall screen for suitable starting enzyme using the optimized

analytical methods, to ascertain the enzyme activity and selectivity. Based on

the enzyme screening results, we shall evaluate the commercial viability of the

enzyme and the processes, as well as the R&D investment needed, if any, to

achieve commercial viability.

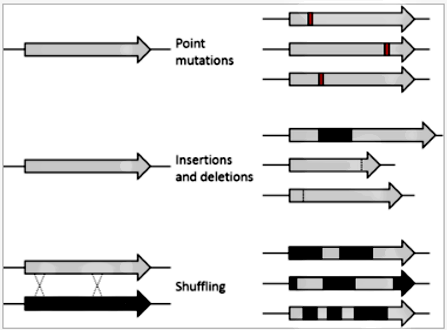

Enzyme Directed Evolution

With our core Enzyme Directed Evolution Platform technology, the properties of

selected enzyme, such as activity, selectivity, and stability, can be

improved. The evolution project will be staged into suitable phases, each with a

specific target and milestones to achieve, with the ultimate aim of achieving

commercial viability. |

|

|

Enzyme Production by Fermentation

We develop robust and highly productive fermentation processes for the

commercial production of enzyme, and then transfer the process to the

collaborator.

Enzymatic process optimizing & Up-scaling

With comprehensive consideration over the enzyme properties, we design and

develop the commercially viable enzyme-catalyzed process and downstream process

for large-scale chemical manufacturing. The technology is optimized for high

productivity and robustment at large scale. Based on the technology transfer

package, the process can be verified in the collaborator’s lab, pilot plant and

finally the production plant.

|

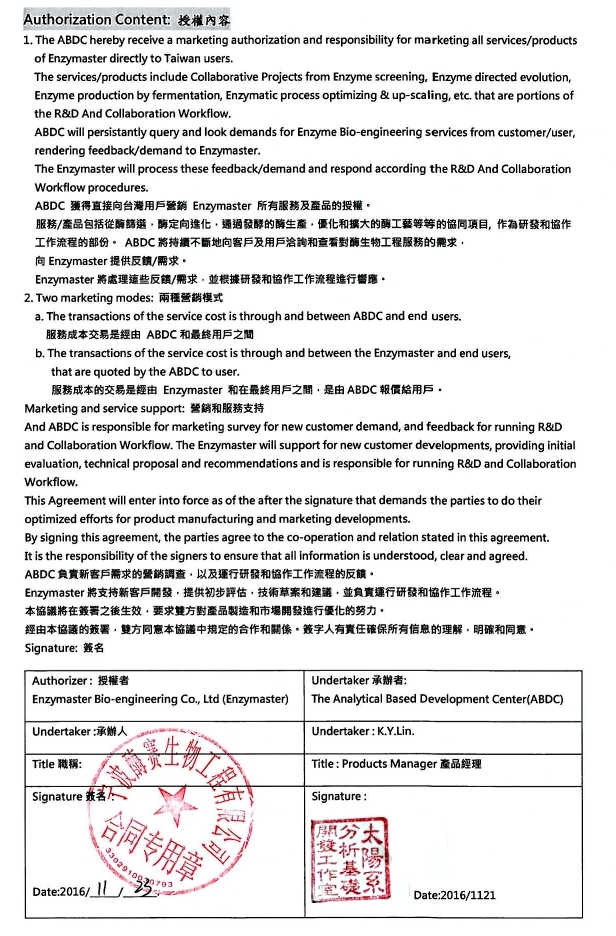

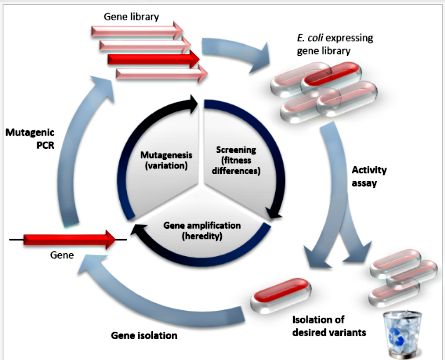

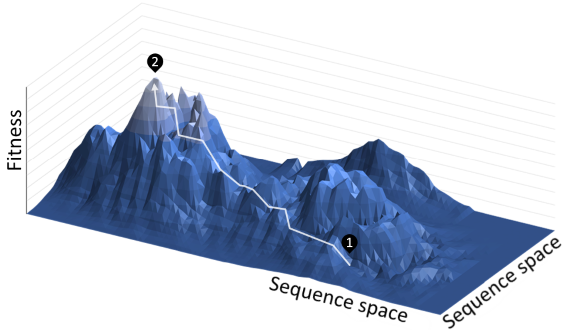

Directed Evolution

https://en.wikipedia.org/wiki/Directed_evolution

Directed evolution (DE) is a method used in protein engineering that mimics the

process of natural selection to evolve proteins or nucleic acids toward a

user-defined goal.[1] It consists of subjecting a gene to iterative rounds of

mutagenesis (creating a library of variants), selection (expressing the variants

and isolating members with the desired function), and amplification (generating

a template for the next round). It can be performed in vivo (in living cells),

or in vitro (free in solution or microdroplet).

Directed evolution is used both for protein engineering as an alternative to

rationally designing modified proteins, as well as studies of

fundamental evolutionary principles in a controlled, laboratory environment.

Principles:

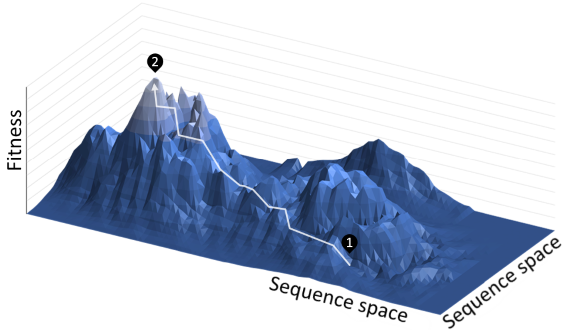

Directed evolution is analogous to climbing a hill on a 'fitness landscape'

where elevation represents the desired property. Each round of selection samples

mutants on all sides of the starting template (1) and selects the mutant with

the highest elevation, thereby climbing the hill. This is repeated until a local

summit is reached (2).

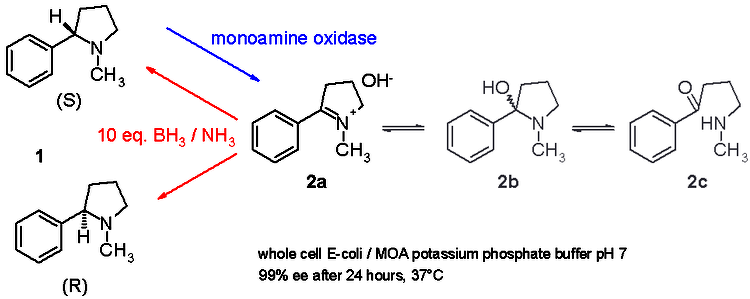

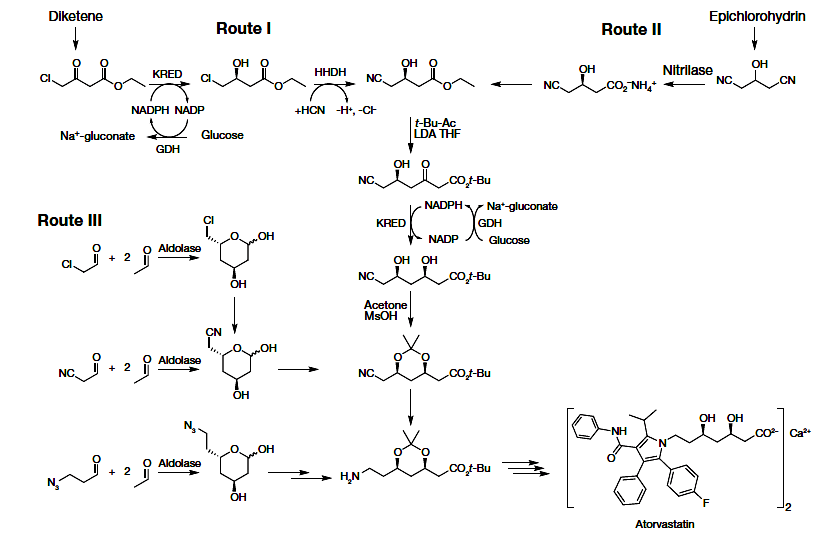

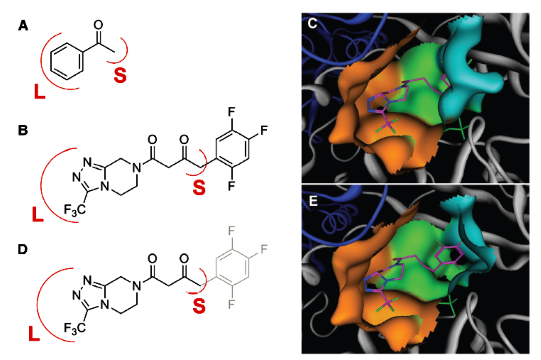

Biocatalytic Asymmetric Synthesis of Chiral Amines from Ketones Applied to

Sitagliptin Manufacture

https://www.ncbi.nlm.nih.gov/pubmed/20558668

Pharmaceutical synthesis can benefit greatly from the selectivity gains

associated with enzymatic catalysis

Here, we report an efficient biocatalytic process to replace a recently

implemented rhodium-catalyzed asymmetric enamine hydrogenation for the

large-scale manufacture of the antidiabetic compound sitagliptin. Starting from

an enzyme that had the catalytic machinery to perform the desired chemistry but

lacked any activity toward the prositagliptin ketone, we applied a substrate

walking, modeling, and mutation approach to create a transaminase with marginal

activity for the synthesis of the chiral amine; this variant was then further

engineered via directed evolution for practical application in a manufacturing

setting. The resultant biocatalysts showed broad applicability toward the

synthesis of chiral amines that previously were accessible only via resolution.

This work underscores the maturation of biocatalysis to enable efficient,

economical, and environmentally benign processes for the manufacture of

pharmaceuticals.

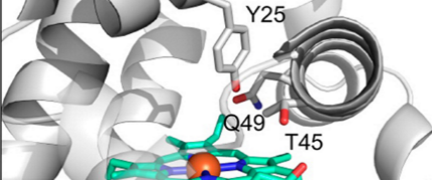

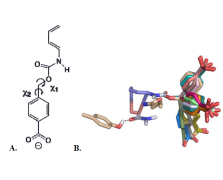

Computational Design of an Enzyme Catalyst for a Stereoselective Bimolecular

Diels-Alder Reaction

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3241958/

http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.169.2720&rep=rep1&type=pdf

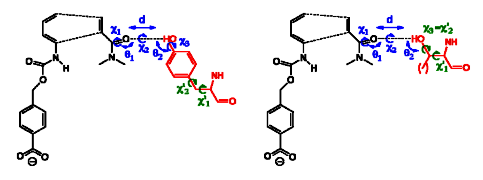

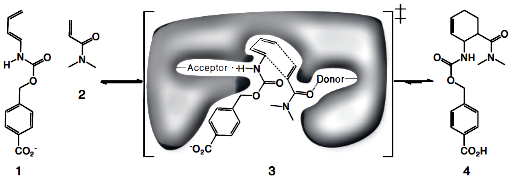

The Diels-Alder reaction is a cornerstone in

organic synthesis, forming two carbon-carbon bonds and up to four new

stereogenic centers in one step. No naturally occurring enzymes have been shown

to catalyze bimolecular Diels-Alder reactions. We describe the de novo

computational design and experimental characterization of enzymes catalyzing a

bimolecular Diels-Alder reaction with high stereoselectivity and substrate

specificity. X-ray crystallography confirms that the structure matches the

design for the most active of the enzymes, and binding site substitutions

reprogram the substrate specificity. Designed stereoselective catalysts for

carbon-carbon bond-forming reactions should be broadly useful in synthetic

chemistry......

The Diels-Alder reaction. Diene (1) and dienophile (2) undergo a pericyclic [4 +

2] cycloaddition (3) to form a chiral cyclohexene ring (4). Also shown in (3) is

a schematic of the design target active site, with hydrogen bond acceptor and

donor groups activating the diene and dienophile and a complementary binding

pocket holding the two substrates in an orientation optimal for catalysis.....

|

|