Inductively Coupled Plasma(ICP)

Atomic/optical emission spectroscopy(ICP-AES/OES),

MASS Spectrometers(ICP-MS).

https://en.wikipedia.org/wiki/Inductively_coupled_plasma |

|

An inductively

coupled plasma (ICP)

or transformer

coupled plasma (TCP)[1] is a type of plasma source in which the energy is supplied by electric currents which are produced by electromagnetic

induction,

that is, by time-varying magnetic fields.[2].

Plasma electron temperatures can range between ~6 000 K and ~10 000

K (~6 eV - ~100 eV),[4]comparable to

the surface of the sun. ICP discharges are of relatively high electron density,

on the order of 1015 cm−3. As a result, ICP discharges have wide applications where

a high-density plasma (HDP) is needed.

·

ICP-AES, a type of atomic emission spectroscopy.

·

ICP-MS, a type of mass spectrometry.

·

ICP-RIE, a type of reactive-ion etching.

·

Exciting a beam of noble gas to the metastable state.[5]

Another benefit of ICP discharges is that they are relatively free of

contamination because the electrodes are completely outside the reaction

chamber. By contrast, in a capacitively

coupled plasma (CCP), the

electrodes are often placed inside the reactor and are thus exposed to the

plasma and subsequent reactive chemical species.

|

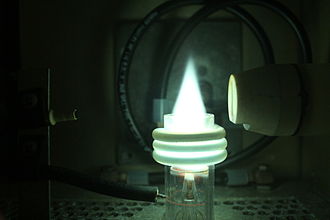

Picture of an analytical ICP torch

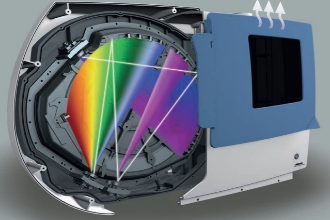

High performance optical system |

|

|

Applications :

Examples of the application of ICP-AES include the determination of metals in

wine,[4] arsenic in

food,[5] and trace

elements bound to proteins.[6]

ICP-OES is widely used in minerals processing to provide the data on grades of

various streams, for the construction of mass balances.

In 2008, the technique was used at Liverpool University to demonstrate that a Chi Rho amulet found in Shepton Mallet and previously believed to be among

the earliest evidence of Christianity in England,[7] only dated to

the nineteenth century.[8][9][10]

ICP-AES is often used for analysis of trace elements in soil, and it is for that

reason it is often used in forensics to ascertain the origin of soil samples

found at crime scenes or on victims etc. Taking one sample from a control and

determining the metal composition and taking the sample obtained from evidence

and determine that metal composition allows a comparison to be made. While soil

evidence may not stand alone in court it certainly strengthens other evidence.

It is also fast becoming the analytical method of choice for the determination

of nutrient levels in agricultural soils. This information is then used to

calculate the amount of fertiliser required to maximise crop yield and quality.

ICP-AES is used for motor oil analysis. Analyzing used motor oil

reveals a great deal about how the engine is operating. Parts that wear in the

engine will deposit traces in the oil which can be detected with ICP-AES.

ICP-AES analysis can help to determine whether parts are failing. In addition,

ICP-AES can determine what amount of certain oil additives remain and therefore

indicate how much service life the oil has remaining. Oil analysis is often used

by fleet manager or automotive enthusiasts who have an interest in finding out

as much about their engine's operation as possible. ICP-AES is also used during

the production of motor oils (and other lubricating oils) for quality control

and compliance with production and industry specifications.

|

|

|

|

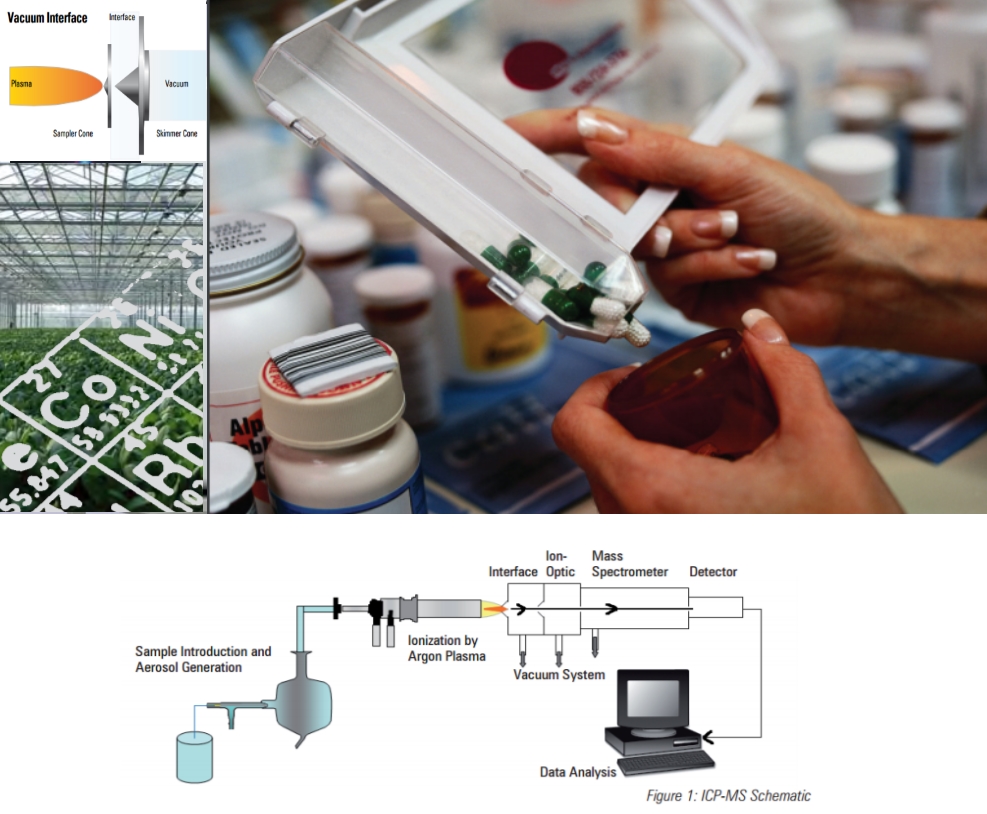

Inductively coupled plasma mass

spectrometry

https://en.wikipedia.org/wiki/Inductively_coupled_plasma_mass_spectrometry

|

Inductively coupled plasma mass spectrometry (ICP-MS) is a type of mass spectrometry which is capable of detecting metals and several non-metals at concentrations as low as one part

in 1015(part per quadrillion, ppq) on non-interfered

low-background isotopes. This is achieved by ionizing the sample with inductively

coupled plasma and then using a mass spectrometer to separate and quantify those ions.

Compared to atomic

absorption spectroscopy, ICP-MS has greater speed, precision, and

sensitivity. However, compared with other types of mass spectrometry, such as thermal

ionization mass spectrometry (TIMS)

and glow discharge mass spectrometry (GD-MS), ICP-MS introduces many interfering

species: argon from the plasma, component gases of air that leak through the

cone orifices, and contamination from glassware and the cones.

The variety of applications exceeds that of inductively coupled plasma atomic emission

spectroscopy and includes isotopic speciation.[citation

needed] Due to possible applications in nuclear technologies,

ICP-MS hardware is a subject for special exporting regulations.

|

Applications

|

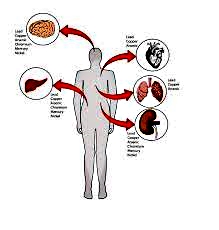

One of the largest volume uses for ICP-MS is in the medical and forensic field,

specifically, toxicology.[citation

needed] A physician may order a metal assay

for a number of reasons, such as suspicion of heavy metal poisoning, metabolic

concerns, and even hepatological issues. Depending on the specific parameters

unique to each patient's diagnostic plan, samples collected for analysis can

range from whole blood, urine, plasma, serum, to even packed red blood cells.

Another primary use for this instrument lies in the environmental field. Such

applications include water testing for municipalities or private individuals all

the way to soil, water and other material analysis for industrial purposes. In

the forensic field, glass ICP-MS is popular for glass analysis.[citation

needed] Trace elements on glass can be

detected using the LA-ICP-MS. The trace elements from the glass can be used to

match a sample found at the crime scene to a suspect. |

|

|

In recent years, industrial and biological monitoring has presented another

major need for metal analysis via ICP-MS. Individuals working in plants where

exposure to metals is likely and unavoidable, such as a battery factory, are

required by their employer to have their blood or urine analyzed for metal

toxicity on a regular basis. This monitoring has become a mandatory practice

implemented by OSHA,

in an effort to protect workers from their work environment and ensure proper

rotation of work duties (i.e. rotating employees from a high exposure position

to a low exposure position).

11 Signs You Have Heavy Metal Toxicity & How To Prevent It :

http://www.naturallivingideas.com/heavy-metal-toxicity-signs/

|

|

ICP-MS is also used widely in the geochemistry field for radiometric dating, in

which it is used to analyze relative abundance of different isotopes, in

particular uranium and lead. ICP-MS is more suitable for this application than

the previously used thermal

ionization mass spectrometry,

as species with high ionization energy such

as osmium and tungsten can

be easily ionized. For high precision ratio work, multiple collector instruments

are normally used to reduce the effect noise on the calculated ratios. |

|

|

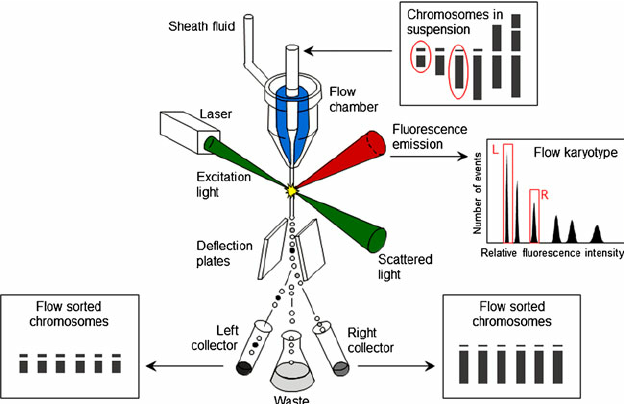

In the field of flow cytometry,

a new technique uses ICP-MS to replace the traditional fluorochromes.

Briefly, instead of labelling antibodies (or

other biological probes) with fluorochromes, each antibody is labelled with a

distinct combinations of lanthanides.

When the sample of interest is analysed by ICP-MS in a specialised flow

cytometer, each antibody can be identified and quantitated by virtue of a

distinct ICP "footprint". In theory, hundreds of different biological probes can

thus be analysed in an individual cell, at a rate of ca. 1,000 cells per second.

Because elements are easily distinguished in ICP-MS, the problem of compensation

in multiplex flow cytometry is effectively eliminated. |

|

In the pharmaceutical industry, ICP-MS is used for detecting inorganic

impurities in pharmaceuticals and

their ingredients. New and reduced maximum permitted exposure levels of heavy

metals form dietary supplements, introduced in USP (United States

Pharmacopeia)

<232>Elemental Impurities—Limits [1] and

USP <233> Elemental Impurities—Procedures,[2] will

increase the need for ICP-MS technology, where, previously, other analytic

methods have been sufficient. |

|

Quantification of proteins and biomolecules

In 2007, a new type of protein tagging reagents called metal-coded

affinity tags (MeCAT)

were introduced to label proteins quantitatively with metals, especially

lanthanides.[3] The

MeCAT labelling allows relative and absolute quantification of all kind of

proteins or other biomolecules like peptides. MeCAT comprises a site-specific

biomolecule tagging group with at least a strong chelate group which binds

metals. The MeCAT labelled proteins can be accurately quantified by ICP-MS down

to low attomol amount of analyte which is at least 2–3 orders of magnitude more

sensitive than other mass spectrometry based quantification methods. By

introducing several MeCAT labels to a biomolecule and further optimization of

LC-ICP-MS detection limits in the zeptomol range

are within the realm of possibility. |

|

|

Elemental analysis

The ICP-MS allows determination of elements with atomic mass ranges 7 to 250 (Li to U), and sometimes higher. Some

masses are prohibited such as 40 due to the abundance of argon in the sample.

Other blocked regions may include mass 80 (due to the argon dimer), and mass 56

(due to ArO), the latter of which greatly hinders Fe analysis unless the instrumentation is

fitted with a reaction chamber. Such interferences can be reduced by using a

high resolution ICP-MS (HR-ICP-MS) which uses two or more slits to constrict the

beam and distinguish between nearby peaks. This comes at the cost of

sensitivity. For example, distinguishing iron from argon requires a resolving

power of about 10,000, which may reduce the iron sensitivity by around 99%.

A single collector ICP-MS may use a multiplier in pulse counting mode to amplify

very low signals, an attenuation grid or a multiplier in analogue mode to detect

medium signals, and a Faraday cup/bucket to detect larger signals. A

multi-collector ICP-MS may have more than one of any of these, normally Faraday

buckets which are much less expensive. With this combination, a dynamic range of

12 orders of magnitude, from 1 ppq to 100 ppm is possible.

|

ICP-OES Spectrometers Key

Features:

Efficiency and Cost :

-

Powerful and cost effective alternative to

sequential ICP and FAA spectrometers.

-

Simultaneous spectrum capture in the 175-770

nm wavelength range - more than twice the sample throughput compared to

sequential instruments when more than 10 elements are analyzed.

-

Low operating cost - optical system requires

only 0.5 L/min purge gas while still offering superb analytical performance in

the UV spectral range.

-

Factory methods can be provided for standard

applications - "Plug and Analyze" without the need for method development.

-

Most accurate results and highest

sensitivity thanks to superior UV performance and constant resolution.

-

Faster out of the gate: less than 10 minutes

warmup time (previously over 30) with the new LDMOS generator.

-

Axial or radial plasma observation.

Power Source:

-

Next generation

plasma power, Laterally Difussed Metal Oxide Semiconductor (LDMOS) generator,

delivers up to 2000W.

-

High power gives great matrix compability at highest plasma loads previously

impossible.

-

Can actually analyze volatile organic samples such as gasoline at room

temperature !

-

Sample can be analyzed in lower dilutions, for lower limit of detection.

-

Extremely robust and trouble free, with advanced design that is completely

short-cut-proof.

-

Air-cool system without external cooling, delivering low running costs.

-

Have no parts subject to wear - minimizing time and expanse.

-

Stablilize much more quickly in less than 10 minutes, ready to start most

measurements.

Excitation System:

-

Free-running generator with a frequency of

27.12 MHz, 0.7-2.0kW power output utilized.

-

For constant plasma power independent from

plasma load.

-

Perfectly suited for volatile organics and

high dissolved solids.

-

Includes automatic plasma ignition.

-

Energy and argon-saving standby mode.

-

Independently adjusts the resonance

frequency, holding the effective plasma power constant over a wide range of

sample loads - Characterized by its robustness, reliability and stability.

Sample Introduction System:

-

Extremely short fluid paths ensure short

measurement and flush times.

-

Thermally insulated illuminated compartment

provides plenty of room to accommodate a large variety of sample introduction

system.

-

Preadjusted setup makes for rapid startup,

without the need for comprehensive optimization.

-

Maintenance friendly sample introduction

system.

Plasma Interface:

-

Radial (SOP) or Axial (EOP) plasma

observation.

-

Radial observation

- Less sensitive to high matrix concentrations and the

influences from organic matrices.

- Smaller observation volume for major elements high

precision determinations applications.

-

Axial observation:

- Evaluates

the entire emission zone, facilitating the analysis of trace contents.

- OPI (Optical Plasma Interface), a bayonet connection

simplifies the use.

- Usually 10 times better detection limits without the

matrix interferences than other axial observation.

- Over 10 years proven.

Optical System:

-

Optimized

Rowland Circle Alignment(ORCA).

-

Covers the entire relevant wavelength range

from 175 to 777 nm.

-

Aluminum hollow section Design quarantees

high thermo stability measurement results.

-

Small optic volume guarantees short start up

times and a purge rate of less than l/min for measurements in the UV range (<200

nm), purged with Argon - optionally Nitrogen.

-

Line-rich spectra can be more easily

processed.

-

Delivers 8 picometers(pm) resolution in the

important range of 165nm-285nm.

-

Delivers 16 picometers(pm) resolution in

higher wavelengths.

-

A twin-interface version enables automatic

axial and radial observations.

Permanently Argon-filled optical chamber:

-

UV gas purification system: Argon

circulation and cleaning system for sealed optical chamber.

-

Recirculating gas througth a small cleaning

catridge,good for 2 years of life.

-

Eliminates waste and

expense than conventional constant purge gas comsuming

(typically more than S3000 per year that also may risks

system comtamination).

-

Helps achieve high stability and excellent

low wavelength performance.

-

Provides stable analytical results

immediately without purge delay and startup.

ICAL Logic System(Intelligent Calibration

Logic):

-

Continuously monitors the optical system and

normalizes the wavelength scale.

-

Calls for an

ICALization (measurement of the ICAL standard) if changes are noticed.

-

Carried out by the control logic if the

instrument is in automatic operation mode.

-

Methods can be easily

transferred among instruments, great for multiple systems of the same type

running.

-

Methods for numerous

and widely varying applications can be developed and offered as factory methods.

Readout System:

-

Linear CCD arrays.

-

Up to 8 orders of

magnitude large dynamic range detectors.

-

Possible to process concentrations from ppb

% range without blooming effects.

-

High speed readout

system, parallelled digital signal processor units.

-

Recording and evaluation of the complete

spectrum in less than 3 seconds.

Cooling system:

-

No complicated, costely external colloing.

-

No water chiller

necessary, saving thousands while eliminating chiller breakdown risk.

-

No optic purge gas required, saves thousands

per year.

-

The only known

completely air-cooled ICP-OES analyzer, the unique innovative OPI-AIR interface.

-

Saves users from

having to buy, install, power, and maintain an elaborate expensive, and often short-lived external cooling system.

Software:

-

Offers theuser clear, structured and easy to

understand control of all instrument functions.

-

Consists of six main

modules for manual, automatic and transient measurements, spectra viewing,

method development and general configuration.

-

1-click routine operation and assistants for

the less frequently used options are available.

-

Even analytical

method creation is simplified vai intelligent assistants/wizards, default

settings, and predefined templates.

-

With dockable windows

and tool bars, the user interface can be customized to specific information

requirements and personal preferences.

-

All of the

measurement parameters, e.g., element and line selection can be edited and

changed as required.

-

Provide easiest

possible operation, offering manual, prompteed manual, or fully automatic

analysis, for personnel with minimal training.

-

Fully compatible with

US EPA, CLP as well as other standards and methods and includes an US FDA 21 CFR

Part 11 compliant user and data management.

Factory Calibrated Methods for wear metal in

oil:

-

Availiable with a

complete factory calibrated method set, ready with no need for initial method

development.

-

Swiftly and

accurately assesses component wear trends, detecting additives, wear elements

and contaminants.

-

Industrial-grade

durability, and surpringly affordable to purchase and operate.

Ergonomic:

-

Moderized ergonomic

design fits on any standard laboratory bench.

-

Polyurethane/aluminum

construction resistant to chemicals and corrosion.

-

Include thoughtful

layout features, as ultra-short fluid paths.

-

Easy, safe

accessibility to components from both sides and front.

-

For fast, convienient service or For fast, convienient service or

maintenance.

More ICP-OES Spectrometers Key Features .....

ICP-MS Spectrometers Key Features:

-

Robust dry vacuum system and

zero-maintenance, free-running, generator.

-

Sample chamber can be accessed by sliding

the front cover to the side.

-

Rapid exchange of the entire sample

introduction system or its individual components.

-

Virtually every combination of nebulizer and

spray chamber is possible.

-

Easily developed by attaching

chromatographs, ultrasonic nebulizers or laser ablation systems.

-

Double-focusing sector field ICP-MS based on

a Mattauch-Herzog geometry with a newly developed ion optic and pioneering

detector technology.

-

With a permanent ion beam going to the

detector.

-

ICAL system logic for continuous optimal

operation.

-

Capable of simultaneously measuring the

complete mass range used for inorganic mass spectrometry from 6Li to 238U.

-

Storage of the data for the complete mass

spectrum enables unprecedented flexibility regarding method development and

reprosessing.

-

Possible to later determine elements in a

sample even when the sample no longer exists.

-

First ICP-MS with simultaneously element

contents and isotope ratio analysis in the entire mass range from Li to U.

-

Rapid fingerprinting, real-time internal

standardization and measurement of transient signals, isotope ratios and isotope

dilution

-

Clearly better precision for development of

new application areas.

-

Leading in productivity and profitability

with high sample throughput rate.

-

Sets new standards for fully simultaneous

analysis, simple operation and highest reliability.

-

Tremendous ion detector readout that

achieves excellent detection limits, precision and accuracy.

-

Compatible with EPA, FDA, CLP and 21 CFR

Part 11 as well as other standards and guidelines.

More ICP-MS Spectrometers Key Features .....

ICP-OES Spectrometers Application Report List:

*** Please login to request anapplication report

ICP-MS Spectrometers Application Report List:

*** Please login to request anapplication report

|