|

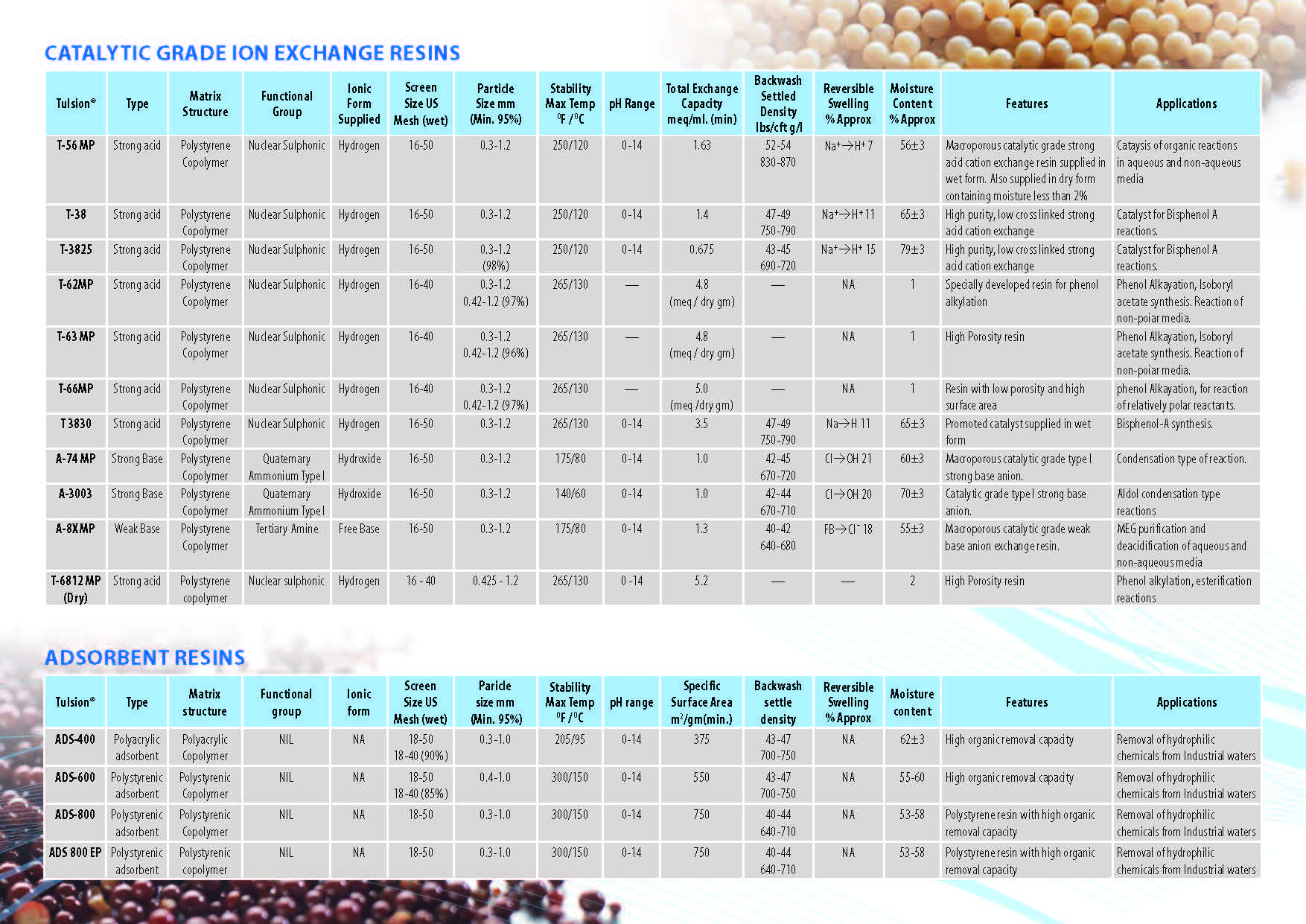

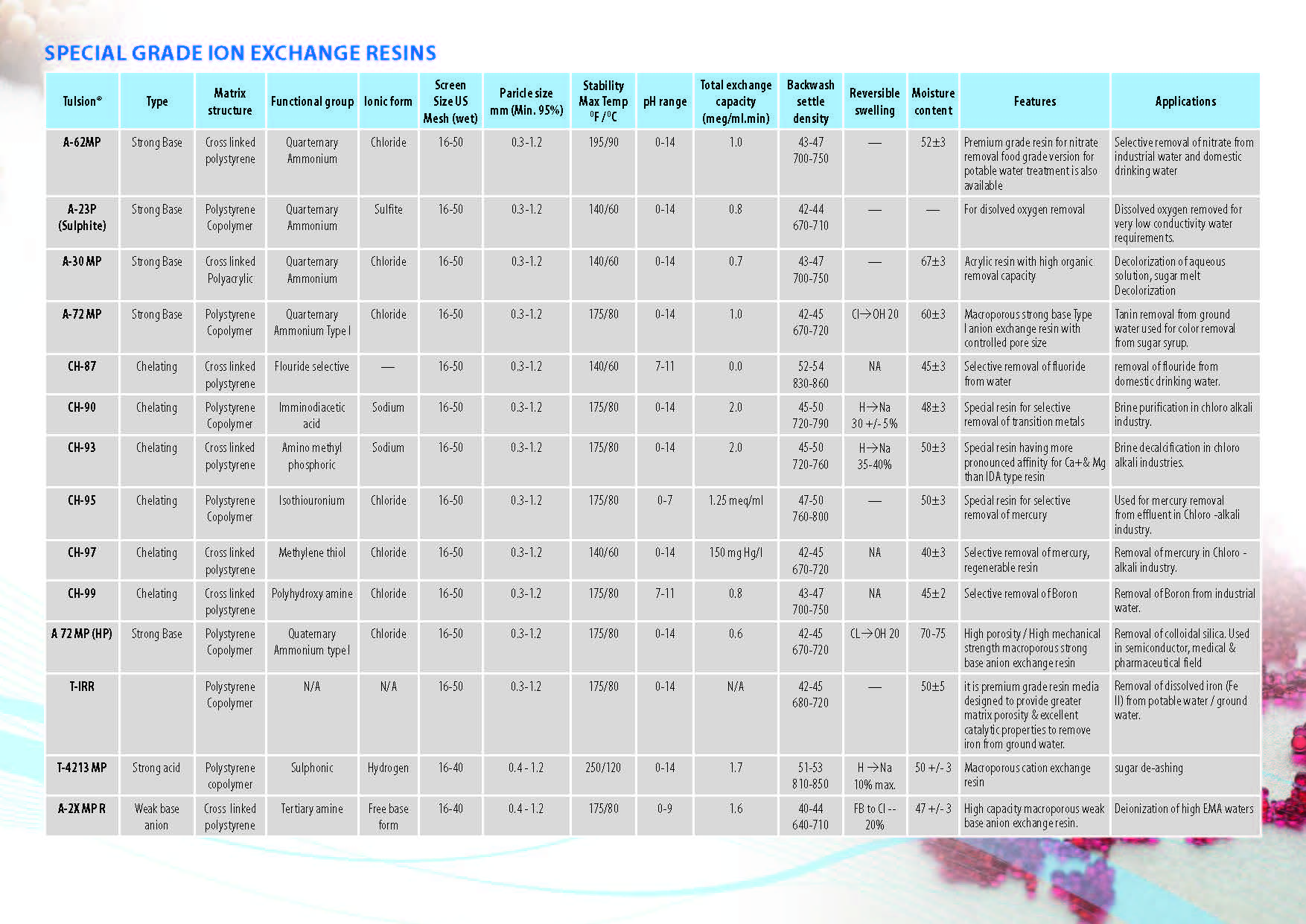

Macro Ion Exchange and Adsorbent Resins

Softening / Demineralisation / Dealkalisation / Nuclear Grade Food Grade /

Polymeric Adsorbent / Polymeric Catalyst

https://en.wikipedia.org/wiki/Ion-exchange_resin

https://en.wikipedia.org/wiki/Adsorption

Ion-exchange resin beads |

An ion-exchange

resin or ion-exchange

polymer is

a resin or polymer

that acts as a medium for ion exchange.

It is an insoluble matrix

(or support structure) normally in the form of small (0.25–0.5 mm radius) microbeads,

usually white or yellowish, fabricated from an organicpolymer substrate.

The beads are typically porous,

providing a large surface area on

and inside them. The trapping of ions occurs

along with the accompanying release of other ions, and thus the process is

called ion exchange. There are multiple types of ion-exchange resin. Most

commercial resins are made of polystyrene sulfonate.[1] |

|

Ion-exchange resins are widely used in different separation,

purification, and decontamination processes. The most common examples are water softening and water purification.

In many cases ion-exchange resins were introduced in such processes as a more

flexible alternative to the use of natural or artificial zeolites.

Also, ion-exchange resins are highly effective in the biodiesel filtration

process. |

|

Most typical ion-exchange resins are based on crosslinked polystyrene. The actual ion-exchanging sites are

introduced after polymerisation. Additionally, in the case of polystyrene,

crosslinking is introduced by copolymerisation of styrene and a few percent of divinylbenzene. Crosslinking decreases

ion-exchange capacity of the resin and prolongs the time needed to accomplish

the ion-exchange processes but improves the robustness of the resin. Particle

size also influences the resin parameters; smaller particles have larger outer

surface, but cause larger head loss in the column processes.[2]

Besides being made as bead-shaped materials, ion-exchange resins are also

produced as membranes. These ion-exchange membranes, which are made of

highly cross-linked ion-exchange resins that allow passage of ions, but not of

water, are used for electrodialysis.

Four main types of ion-exchange resins differ in their functional groups:

- strongly acidic, typically featuring sulfonic acid groups, e.g. sodium polystyrene sulfonate or polyAMPS,

- strongly basic, typically featuring quaternary amino groups, for example, trimethylammonium groups, e.g. polyAPTAC),

- weakly acidic, typically featuring carboxylic acid groups,

- weakly basic, typically featuring primary,

secondary, and/or tertiary amino groups, e.g. polyethylene amine.

Specialised ion-exchange resins are also known such as chelating resins (iminodiacetic acid, thiourea-based resins, and many others). Anion resins

and cation resins are the two most common resins used in the ion-exchange

process. While anion resins attract negatively charged ions, cation resins

attract positively charged ions.....

|

|

The presence of certain metal ions like calcium and magnesium principally as bicarbonates, chlorides, and sulfatesin water causes a variety of problems.[1]

Hard water leads to the buildup of limescale, which can foul plumbing, and promote galvanic corrosion.[2] In industrial

scale water softening plants, the effluent flow from the re-generation process

can precipitate scale that can interfere with sewage systems.[3]

The slippery feeling experienced when using soap with

soft water occurs because soaps tend to bind to fats in the surface layers of skin, making soap

molecules difficult to remove by simple dilution. In contrast, in hard-water

areas, the rinse water contains calcium or magnesium ions that form insoluble salts, effectively removing the residual soap from the

skin but potentially leaving a coating of insoluble stearates on tub and shower

surfaces, commonly called soap scum.[4]

|

Limescale in

a PVC pipe |

The desirability of these competing effects varies by

personal preference, and those who dislike the effects of soft water may choose

to harden the water by adding chemicals such as baking soda, calcium chloride, or magnesium sulfate.[5]

https://en.wikipedia.org/wiki/Water_softening#Rationale |

Water softening is

the removal of calcium, magnesium,

and certain other metal cations in hard water.

The resulting soft water requires less soapfor

the same cleaning effort, as soap is not wasted mopping up calcium ions. Soft

water also extends the lifetime of plumbing by

reducing or eliminating scale build-up

in pipes and fittings. Water softening is usually achieved using lime softening or ion-exchange resins but

is increasingly being accomplished using nanofiltration or reverse osmosis membranes.

|

Control room and schematics of the water purification plant of Lac de Bret,

Switzerland

|

Water purification is the process of

removing undesirable chemicals, biological contaminants, suspended solids, and

gases from water. The goal is to produce water fit for specific purposes. Most

water is purified and disinfected for human consumption (drinking water), but water purification may also

be carried out for a variety of other purposes, including medical,

pharmacological, chemical, and industrial applications. The methods used include

physical processes such as filtration, sedimentation, and distillation; biological processes such as slow sand filters or biologically active carbon; chemical processes

such as flocculation and chlorination; and the use of electromagnetic

radiation such as ultraviolet light.

Water purification may reduce the concentration of particulate matter including suspended particles, parasites, bacteria, algae, viruses, and fungi as well as reduce the concentration of

a range of dissolved and particulate matter.

https://en.wikipedia.org/wiki/Water_purification

|

Carbonate and bicarbonate alkalinities are decomposed by heat in boiler water

releasing carbon dioxide into the steam. This

gas combines with the condensed steam in process equipment and return lines to

form carbonic acid. This depresses the pH value of the condensate returns and results

in corrosive attack on the equipment and piping.

In general, a dealkalizer is best applied to boilers operating below 700 psi (48 bar). In order to justify installation of a

dealkalizer on low-pressure boilers, the alkalinity content should be above 50 ppm with the amount of make-up

water exceeding 1,000 gallons (approx. 4,000 litres) per day.

Cooling system make-up will also benefit from reduced alkalinity. The

addition of a dealkalizer to a cooling water system will substantially reduce

the amount of acid required to treat the same amount of

water.

https://en.wikipedia.org/wiki/Dealkalization_of_water

Adsorption is present in

many natural, physical, biological and chemical systems and is widely used in

industrial applications such as heterogeneous catalysts,[5][6] activated charcoal,

capturing and using waste heat to

provide cold water for air conditioning and other process requirements (adsorption chillers), synthetic resins,

increasing storage capacity of carbide-derived carbons and water purification.

Adsorption, ion exchange and chromatography are

sorption processes in which certain adsorbates are selectively transferred from

the fluid phase to the surface of insoluble, rigid particles suspended in a

vessel or packed in a column. Pharmaceutical industry applications, which use

adsorption as a means to prolong neurological exposure to specific drugs or

parts thereof,[citation

needed] are

lesser known.

https://en.wikipedia.org/wiki/Adsorption

|

Heterogeneous catalysis is the type of catalysis where the phase of the catalyst differs from the phase of the reactants.[1] This contrasts

with homogeneous catalysis where

the reactants and catalyst exist in the same phase. Phase distinguishes between

not only solid, liquid, and gas components, but also immiscible mixtures (e.g. oil and water), or anywhere an interface is present. Catalysts are

useful because they increase the rate of a reaction[2] without

themselves being consumed and are therefore reusable.

Heterogeneous catalysis typically involves solid phase

catalysts and gas phase reactants.[3] In this case,

there is a cycle of molecular adsorption, reaction, and desorption occurring at

the catalyst surface. Thermodynamics, mass transfer, and heat transfer influence

the rate (kinetics) of reaction.

Heterogeneous catalysis is very important because it

enables faster, large-scale production and the selective product formation.[4] Approximately

35% of the world's GDP is influenced by catalysis.[5] The production

of 90% of chemicals (by volume) is assisted by solid catalysts.[3] The chemical

and energy industries rely heavily on heterogeneous catalysis. For example, the

Haber-Basch process uses metal-based catalysts in the synthesis of ammonia, an important component in fertilizer; 144

million tons of ammonia were produced in 2016.[6]

https://en.wikipedia.org/wiki/Heterogeneous_catalysis

|

|

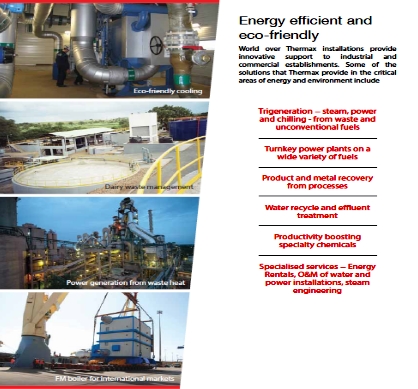

Leading with Quality, Performance and Cost

Our partners, the

https://www.thermaxglobal.com/ , is a Asia's leading manufacturer & exporter

of TULSION® brand Ion Exchange Resins and a pioneer in the field of MAXTREAT®

brand Fuel & Water treatment chemicals. Thermax also supplies chemicals for

paper industry and for oil field operations. Powered by technological expertise

and capabilities honed over more than 4 decades and backed by a strong dealer

network, the Chemical Division serves customers across the globe and supports

the entire range of Thermax's energy and environment businesses. Backed by

extensive R & D experience and equipped with modern research and

state-of-the-art manufacturing facilities the business has built a client base

in USA, Japan, South East Asia, India & Middle East.

Thermax-Corporate-Brochure-Technology-In-Action.pdf

Chemical Division Product Portfolio :

Ion Exchange Resins

:

Ion Exchange Resins Applicationwise

Ion Exchange Resins Typewise

Water Treatment Chemicals

Fuel Additives & Fireside Chemicals

Green Chemicals

Sugar Industry Chemicals

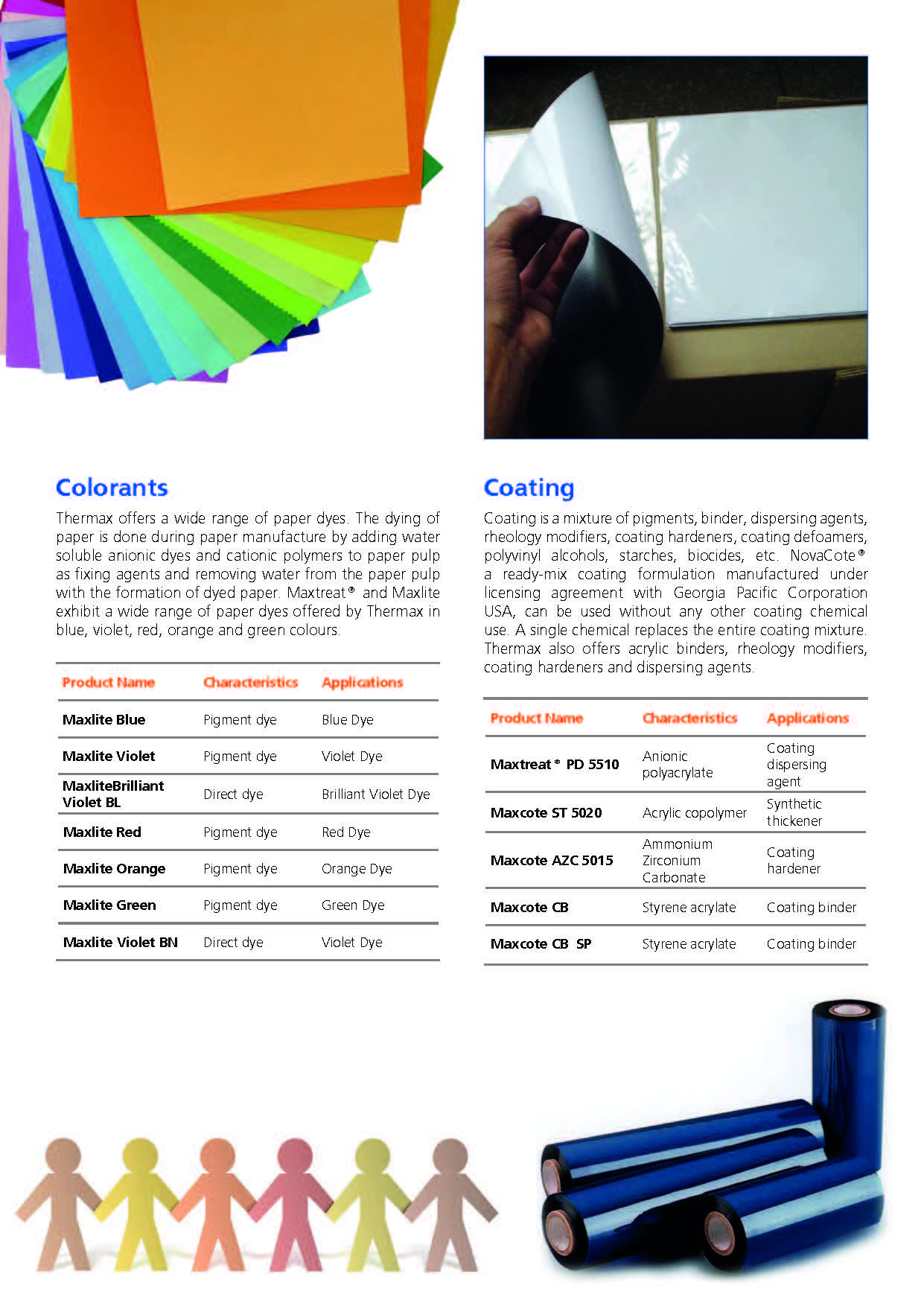

Paper Chemicals

Oil Field Chemicals

Primary Recovery Oil Field Chemicals

Secondary Recovery Oil Field Chemicals

Other Oil Field Chemicals

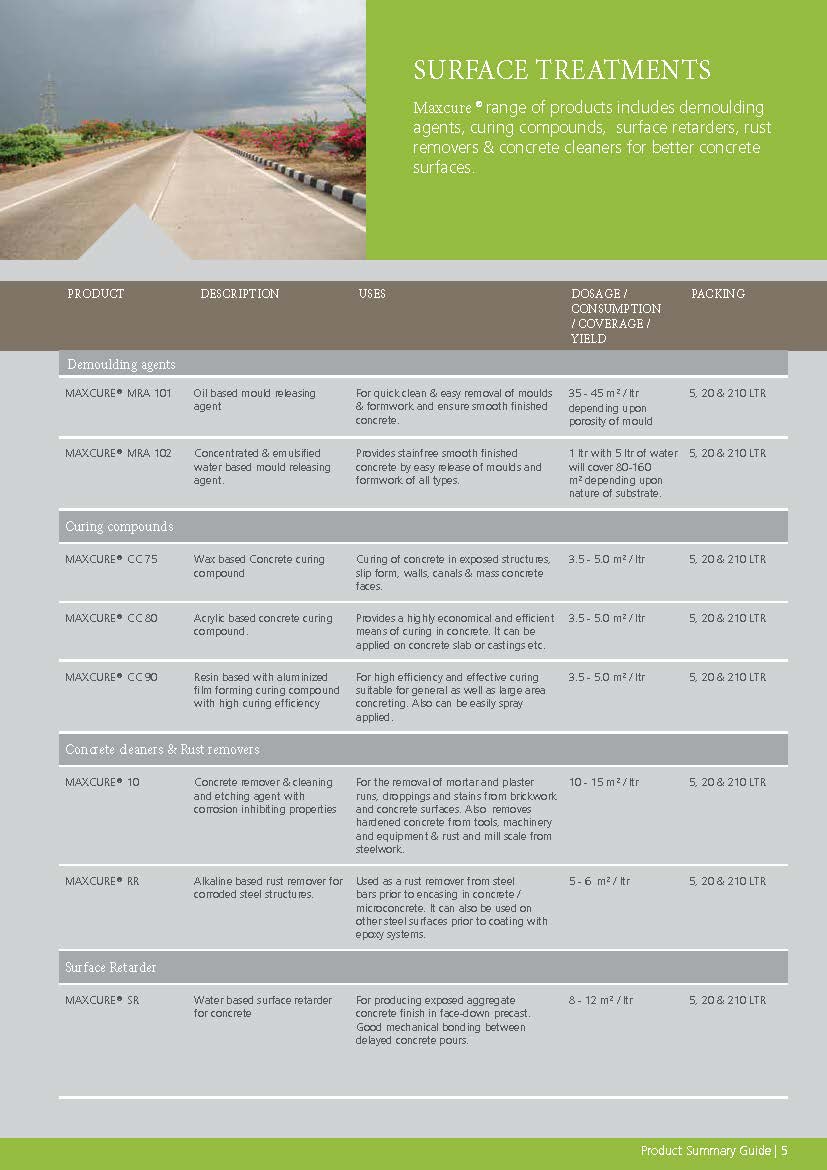

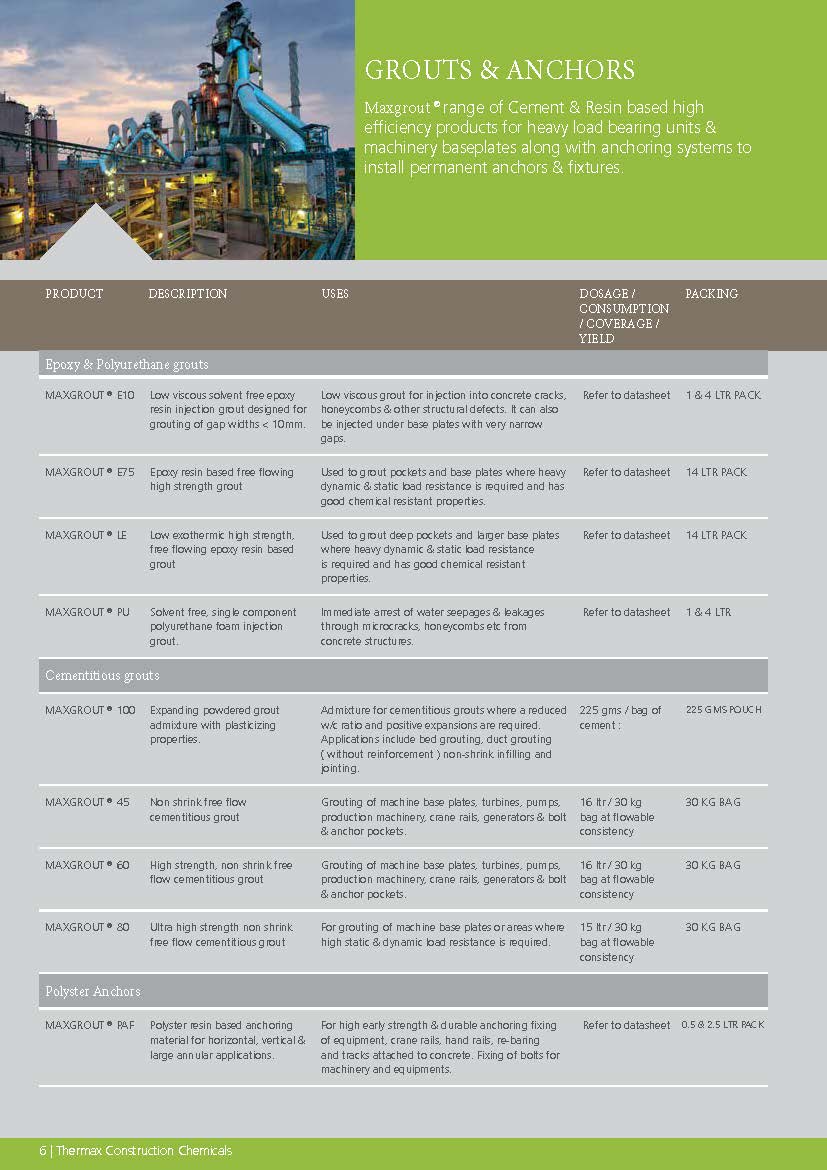

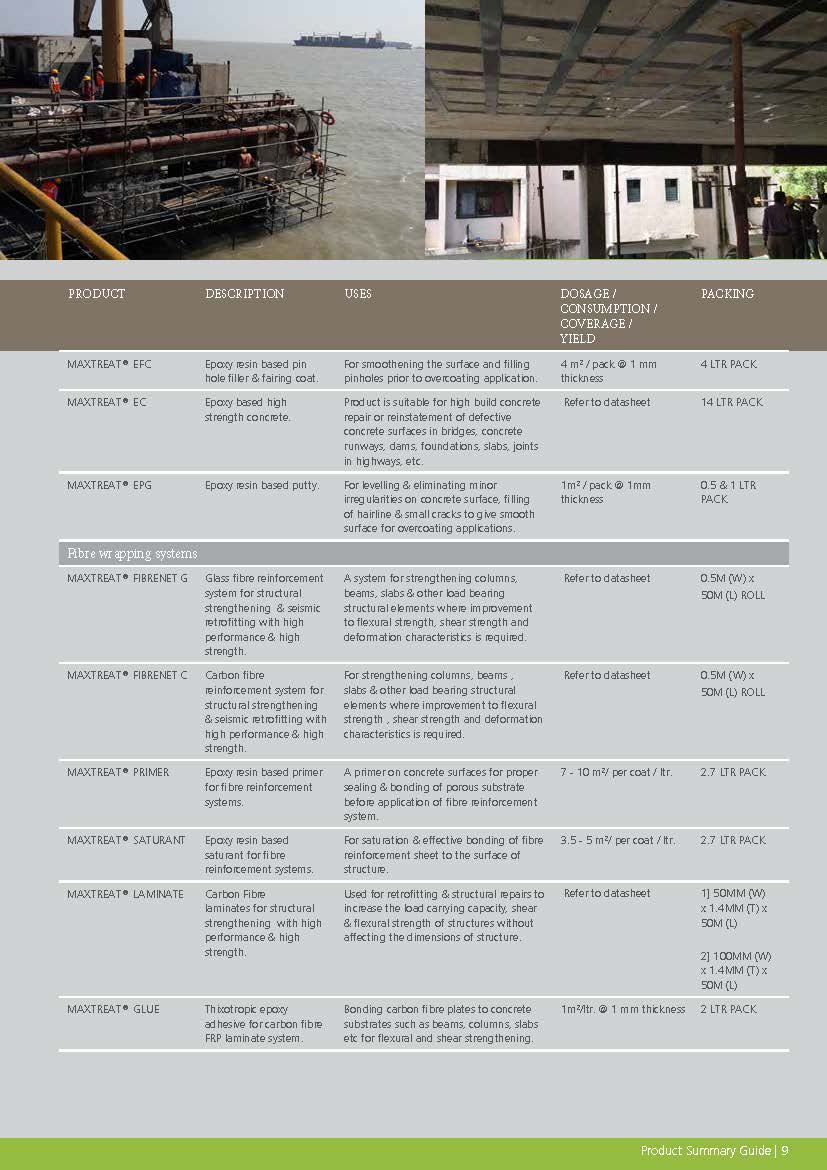

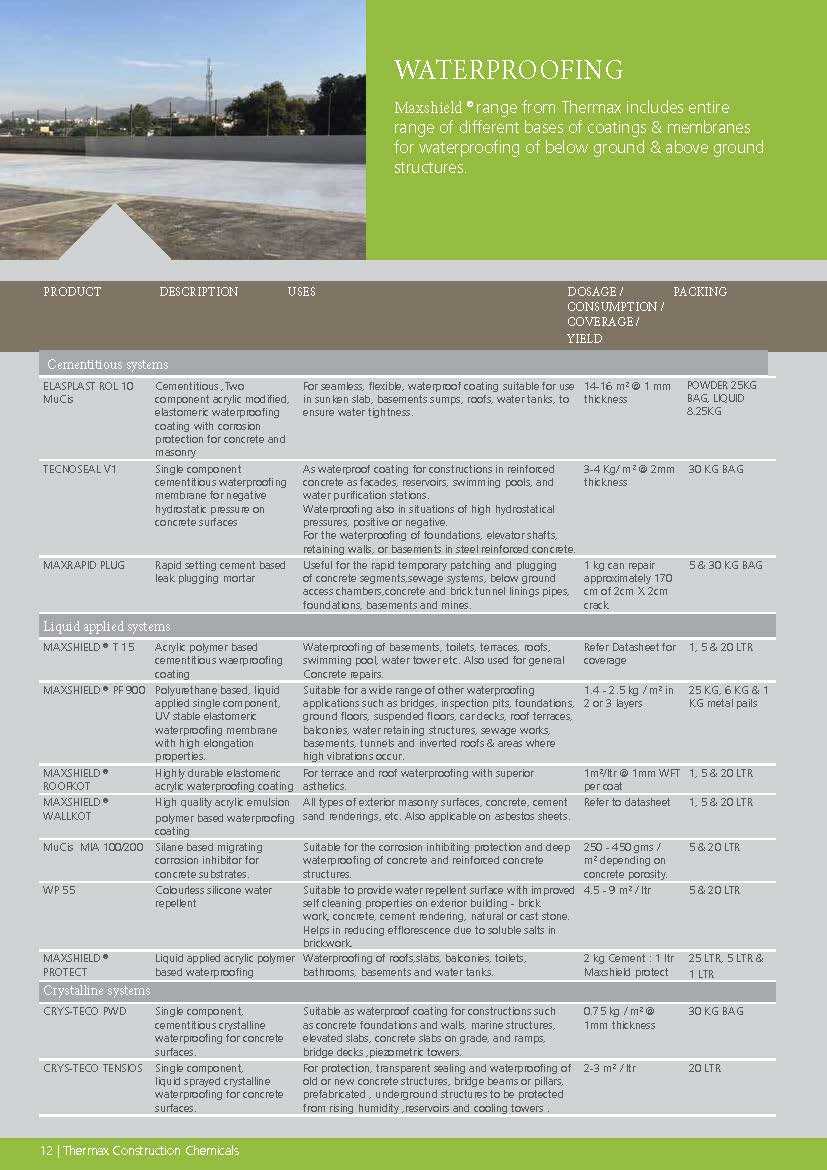

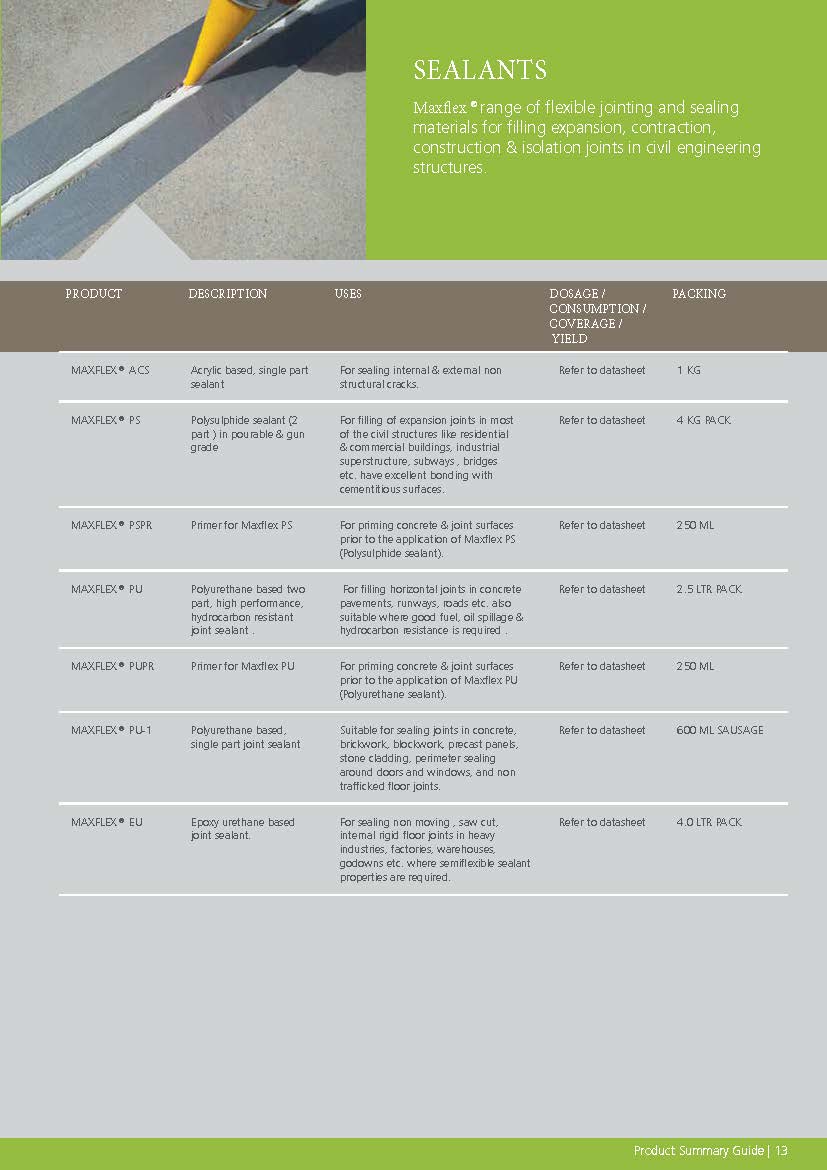

Construction Chemicals

Ion Exchange Resins SDS

Specialty Chemicals for Water and Fuel Management

Chemicals

Paper Industry

Sustainable Construction Solutions

|