|

Micro Reactors :

|

|

|

|

|

|

MAE-C1 Microreactor Connecting System |

MAE-T Microreactor Transportation System |

MAE-V1 Microreactor Connecting System |

MAE-V2 Microreactor Connecting System |

|

|

|

|

|

MRI Industrial Microreactor |

MRS Stock Microreactor |

MRE Microreactor |

MHS, Stocked Microreactor, Heat Exchanger |

|

|

|

|

|

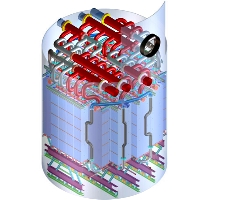

MHI, Industrial Microreactor, Heat Exchanger |

MHE, Microreactor, Heat Exchanger |

MEL, Lab Engineering Platform, Microreactor, Lab

microreactor |

ME-BaSO4, Nano Material, Engineering Platform,

Microreactor |

|

|

|

|

|

ME- PCl3,Engineering Platform, Microreactor,

Nano Powder |

Microreact connector, One way valve, MAE-V3 |

|

|

| |

|

|

|

|

Heat Exchangers :

|

|

|

|

|

|

Thermo-plates, Pesticide industrial, Cooling

equipment |

SCGG GAS-GAS HEAT EXCHANGER |

SCHC THERMO-PLATE CONDENSER |

SCHE SOLID DUST-FREE COOLER |

|

|

|

|

|

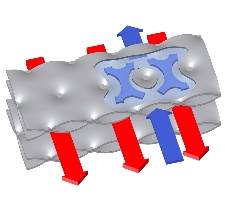

SCHR THERMO-PLATE REACTOR |

SCLG LIQUID GAS HEAT EXCHANGERS |

|

|

| |

|

|

|

|

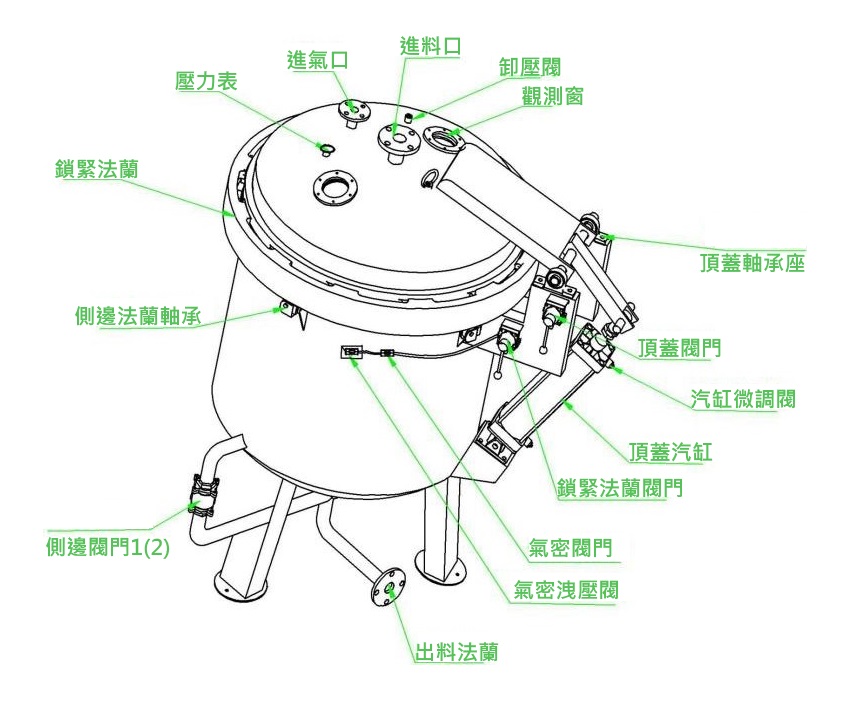

Pneumatic driving

Pressure Filters :

Pressure filters, with

the exception of the Rotary Drum Filter, are semi-continous type

machines

that enter a wash and cake discharge mode at the end of the

fitration cycle.

The fitration cycle may extend from 5-10 minutes on cake

filration applications

and up to many hours

for the polishing of liquids.

Leading with Quality, Performance and Cost :

Our partners, the FRAPP'S Chemical

Industrial is a high-tech enterprise that focuses on research

and production of the Pneumatic Driving Pressure Filter with

independent intellectual properties, that based on the

integration and refining of the global research and engineering

practice.

http://www.frappsbio.com/

FLG pneumatic pressure filter is independently developed

filter of our company, and is one kind of new type, efficient,

energy-saving and sophisticated new product. It is suitable for

solid-liquid separation for a variety of suspensions, with a

wide range of application, good separation effect, simple

structure, easy operation, safety and reliability, and have been

widely used in medicine, food , chemicals, dyes, coal washing,

petroleum, metallurgy and other fields. It is also suitable for

various fields that need solid-liquid separation, as the

treatments of industrial wastes for pharmaceutical, textile,

printing and dyeing, paper, leather, MSG(Monosodium Glutamate)

and others, and for urban sewage.

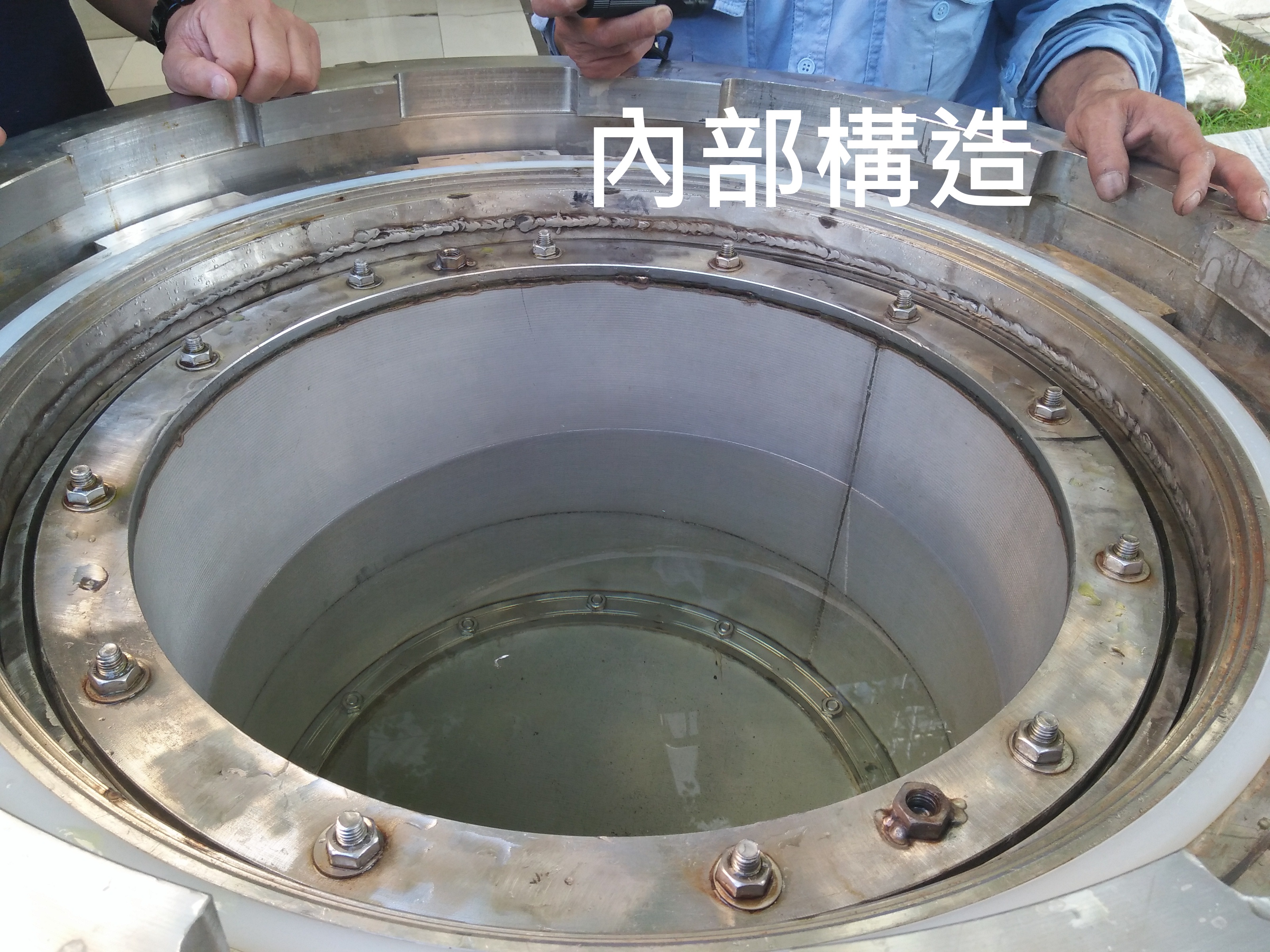

The filter materials and structures inside the filter is

composed by the high precision 316L sintered multi-layer plate

filter sieve. The liquid flows into the sintered plate filter

sieve from the inlet, filtered and flow out with solids

intercepted in filtering bag inside of the sintered

plate filter sieve. FLG pneumatic pressure filter system is

mainly based on the principle of surface filtration and

adsorption filtration, with accurate, efficient, stable

features, and can reach filter diameter precision of 5-200μm.

Compared with ordinary filter, FLG series Pressure Filter has

the following characteristics:

1. Replace Centrifuge.

2. Entire system operation is sealed, no pollution

Pressure Filter is a sealed system that uses pneumatic A, B,

C-type flange pneumatic locking technology, Y-type silicone

rubber and fluorinated rubber gas seals, that features excellent

sealing, no odor spills, and preventing from leakage.

3. Adopt switching devices driven by compressed air with no

power demanded, that reduces risk factors and is safe and

reliable.

4. With large filtering area, fast filtering speed to shorten

the

production cycle.

5. Applicable on pressurized filtering for media from various

solid-liquid separation, activated carbon separation, etc.

6. Filter precision: 5-200um (+/-2%).

System Structure

Pressure Filter is a cylindrical steel container.

The liquid enters

through the inlet, filtered by the high-precision 316L sintered

filter plate inside,

then to the reservor tank department.

The impurities / solids will be intercepted into filter bag of

the sintered plate .

Pressure filter system is mainly based on three filtration

principles, that is

depth filtration and surface filtration,

and adsorption filtration, and has accurate, high efficient and

stable characteristics.

The main technical

parameters:

| Specification

|

Diameter

|

Height

|

Volume

|

Material |

| FLG-600 |

600mm |

400mm |

110L |

Stainless steel /

Sintered plate |

| 750mm |

210L

|

| FLG-800 |

800mm |

400mm |

200L

|

Stainless steel /

Sintered plate |

| 750mm |

380L

|

| FLG-1000 |

1000mm |

400mm |

310L

|

Stainless steel /

Sintered plate |

| 750mm |

580L |

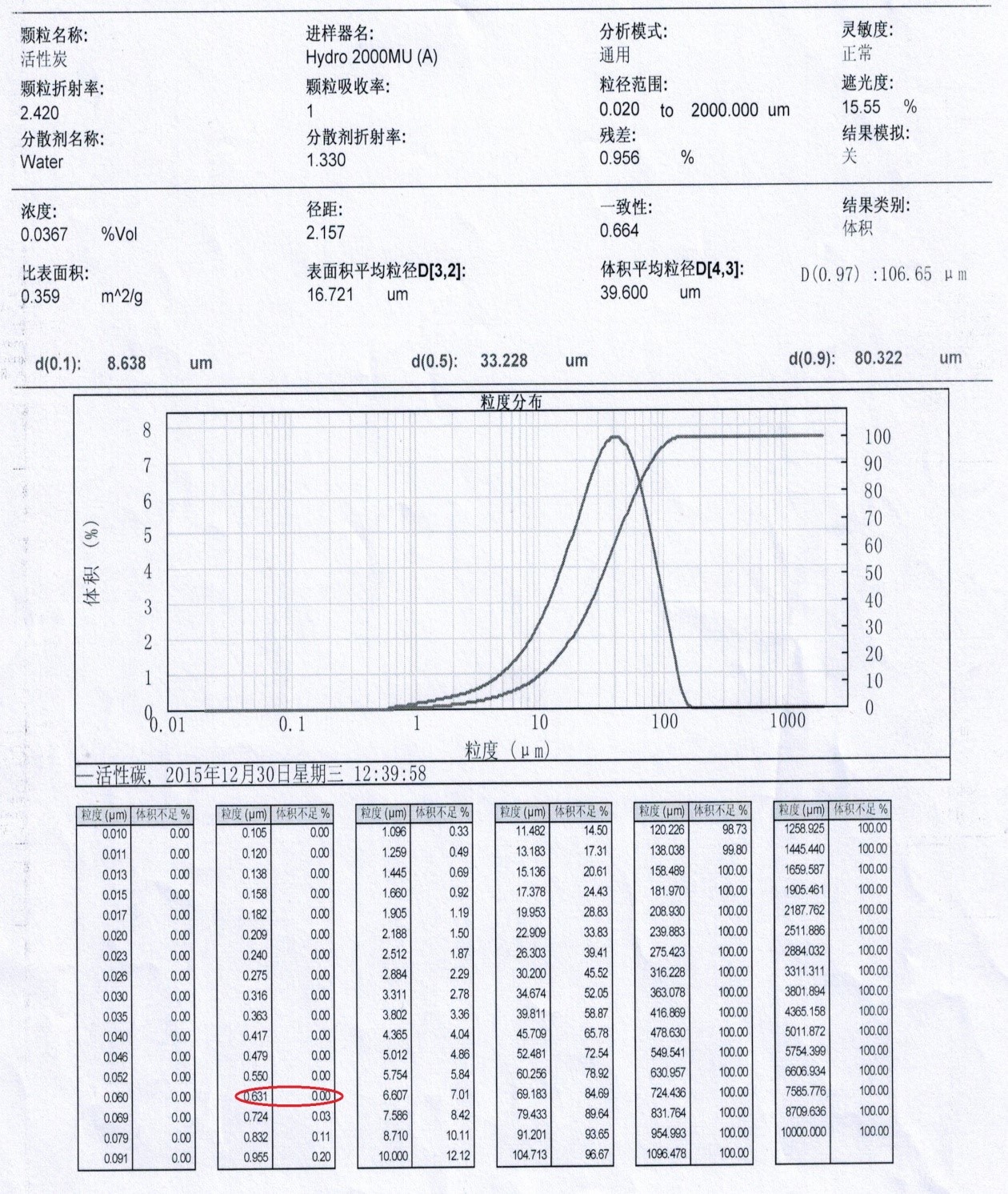

AW

Activated carbon particle

size distribution

|