|

Process Analytical Technology, PAT - Organic

PAT / NIR / FTIR / ATR / UV–VIS / UAN / DEF/ AdBlue / DAP Biodiesel / Lubricant / MON / RVP Paraffin / Petroleum wax / Drink(Beverage) / Cooking oil/ Sugar refinery / Water Quality ( Pt - Co ) / Raw water / Wastewater

Bio-Technology Raw Materials and Consumables from Taiwan

Knowledge Bases :

I. Process analytical technology (PAT)II. Industrial processesIII. PAT tools

Near-infrared spectroscopy (NIRS)

Fourier transform infrared spectroscopy (FTIR)

Attenuated total reflection (ATR)

UV–visible spectrophotometry

Pre-shipment inspection (PSI)

Applications :

IV. Composition Measurement

Nitrogen fertilizers

UAN ( Urea & Ammonium Nitrate )

Diesel exhaust fluid (DEF; AUS 32, AdBlue)

Diammonium phosphate (DAP)

V. Color Dosing and Dilution Control

Aromatic compounds

Biodiesel

Lubricant

Octane rating

Motor Octane Number (MON)

Cycloalkanes (Naphthenes)

Alkane (Paraffin)

Reid vapor pressure (RVP)

Drink (Beverage)

Beer

Color quality scale (CQS)

Cooking oil

Sugar refinery

Paraffin wax (Petroleum wax)

VI. Water Quality ( Pt - Co )

Raw water

Wastewater

I. Process Analytical Technology, PAT

The long-term goals of PAT are to: reduce production cycling time, prevent rejection of batches, enable real time release, increase automation and control, improve energy and material use, facilitate continuous processing.

|

Process analytical technology (PAT) has been defined by the United States Food and Drug Administration (FDA) as a mechanism to design, analyze, and control pharmaceutical manufacturing processes through the measurement of critical process parameters (CPP) which affect critical

quality attributes (CQA).

The concept actually aims at understanding the processes by defining their CPPs, and accordingly monitoring them in a timely manner (preferably in-line or on-line) and thus being more efficient in testing while at the same time reducing over-processing, enhancing consistency and minimizing rejects.

|

II. Industrial Processes

The long-term goals of PAT are to: reduce production cycling time, prevent rejection of batches, enable real time release, increase automation and control, improve energy and material use, facilitate continuous processing.

|

Industrial processes are

procedures involving chemical, physical, electrical or mechanical steps

to aid in the manufacturing of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy industry..

Chemical processes by main basic materialCertain chemical process yield important basic materials for society, e.g., (cement, steel, aluminum,

and fertilizer).

However, these chemical reactions contribute to climate change by

emitting carbon dioxide,

a greenhouse gas,

through chemical reactions, as well as through the combustion of fossil fuels to

generate the high temperatures needed to reach the activation energies of

the chemical reactions.

|

III. PAT tools

Fundamental to process analytical technology (PAT) initiatives are the basics of multivariate

analysis (MVDA)

and design of experiments (DoE).

This is because analysis of the process data is a key to understand the process and keep it under multivariate statistical control.

|

PAT tools

In order to implement a successful PAT project, a combination of three main PAT tools is essential:

- Multivariate data acquisition and data analysis tools: usually advanced software packages which aid in design of experiments, collection of raw data and statistically analyzing this data in order to determine what parameters are CPP.

- Process analytical chemistry (PAC) tools: in-line and on-line analytical instruments used to measure those parameters that have been defined as CPP. These include mainly near infrared spectroscopy (NIRS); but also include biosensors, Raman spectroscopy, fiber

optics and others.

- Continuous improvement and/or knowledge management tools: paper systems or software packages which accumulate Quality Control data acquired over time for specific processes with the aim of defining process weaknesses and implementing and monitoring process improvement initiatives. These products may be the same or separated from the statistical analysis tools above.

|

Near-IR absorption spectrum of dichloromethane showing

complicated overlapping overtones of

mid IR absorption features.

|

Near-infrared spectroscopy (NIRS)

is a spectroscopic method

that uses the near-infrared region

of the electromagnetic spectrum (from

780 nm to 2500 nm). Typical applications include medical and physiological diagnostics and research including blood sugar, pulse

oximetry, functional

neuroimaging, sports medicine, elite sports training, ergonomics, rehabilitation, neonatal research, brain

computer interface, urology (bladder

contraction), and neurology (neurovascular

coupling). There are also applications in other areas as well such as pharmaceutical, food and agrochemical quality control, atmospheric

chemistry, combustion research and astronomy..

|

Light undergoes multiple internal reflections in the crystal of high refractive index, shown in yellow. The sample is in contact with the crystal.

|

Attenuated total reflection (ATR)

is a sampling technique used in conjunction with infrared spectroscopy which

enables samples to be examined directly in the solid or liquid state

without further preparation. ATR uses a property of total internal reflection resulting in an evanescent

wave. A beam of infrared light is

passed through the ATR crystal in such a way that it reflects at least once off the internal surface in contact with the sample. This reflection forms the evanescent wave which extends into the sample. The penetration depth into the sample is typically between 0.5 and 2 micrometres, with the exact value determined by the wavelength of light, the angle of incidence and the indices of refraction for the ATR crystal and the medium being probed..

|

Does the product work in its intended manner? Important for electronics, toys and the like.

|

Pre-shipment inspection (also preshipment inspection or PSI) is a part of supply chain management and an important quality control method for checking the quality of goods clients buy from suppliers.

PSI helps ensure that production complies with the governing specification, contract, or purchase order. A final random inspection (FRI) checks finished products, often when at least 80% of an order has been produced and export-packed. Samples are selected at random, according to standards and procedures.

|

IV. Composition Measurement

Physical and Chemical Characteristics of UAN Solutions

| Grade, |

28 |

30 |

32 |

| Ammonium nitrate (%): |

40 |

42 |

45 |

| Urea (%): |

30 |

33 |

35 |

| Water (%): |

25.5 30

|

25 |

20 |

| Specific gravity at 16 °C: |

1.283 |

1.303 |

1.320 |

| Salt-out temperature (°C): |

-18 |

-10 |

-2 |

|

UAN is

a solution of urea and ammonium

nitrate in

water used as a fertilizer.

The combination of urea and ammonium nitrate has an extremely low critical relative humidity (18%

at 30 °C) and can therefore only be used in liquid fertilizers. The most commonly used grade of these fertilizer solutions is UAN 32.0.0 (32%N) known as UN32 or UN-32, which consists of 45% ammonium nitrate,

35% urea and

only 20% water. Other grades are UAN 28, UAN 30 and UAN 18. The solutions are quite corrosive towards mild steel (up to 500 milliinches per year on C1010 steel) and are therefore generally equipped with a corrosion inhibitor to protect tanks, pipelines, nozzles, etc. Urea–ammonium nitrate solutions should not be combined with calcium ammonium nitrate (CAN-17) or other solutions prepared from calcium nitrate. A thick, milky-white insoluble precipitate forms that may plug nozzles..

|

V. Color Dosing and Dilution Control

Not all aromatic compounds are benzene-based; aromaticity can also manifest in heteroarenes,

which follow Hückel's rule (for

monocyclic rings

|

Aromatic compounds are

those chemical compounds (most

commonly organic)

that contain one or more rings with pi

electrons delocalized

all the way around them. In contrast to compounds that exhibit aromaticity, aliphatic

compounds lack

this delocalization. The term "aromatic" was assigned before the physical mechanism determining aromaticity was discovered, and referred simply to the fact that many such compounds have a sweet or pleasant odour; however, not all aromatic compounds have a sweet odour, and not all compounds with a sweet odour are aromatic compounds. Aromatic hydrocarbons,

or arenes,

are aromatic organic compounds containing solely carbon and hydrogen atoms. The configuration of six carbon atoms in aromatic compounds is called a "benzene ring", after the simple aromatic compound benzene,

or a phenyl group

when part of a larger compound.

|

In 1999, an estimated 37,300,000 tons of lubricants were consumed worldwide.

|

A lubricant is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, transporting foreign particles, or heating or cooling the surfaces. The property of reducing friction is known as lubricity.

In addition to industrial applications, lubricants are used for many other purposes. Other uses include cooking (oils and fats in use in frying pans, in baking to prevent food sticking), bioapplications on humans (e.g. lubricants for artificial joints), ultrasound examination, medical examination, and sexual intercourse. It is mainly used

to reduce friction and to contribute to a better and efficient functioning of a mechanism.

|

A US gas station pump offering five different (R+M)/2 octane ratings

|

An octane

rating, or octane number, is a standard measure of a fuel's

ability to withstand compression in

an internal combustion engine without detonating.

The higher the octane number, the more compression the fuel can withstand before detonating. Octane rating does not relate directly to the power output or the energy content of the fuel per unit mass or volume, but simply indicates gasoline's capability against compression. In broad terms, fuels with a higher octane rating are used in higher-compression gasoline

engines, which may yield higher power. Such higher power comes from the fuel's higher compression by the engine design, and not directly from the gasoline.

Another type of octane rating, called Motor

Octane Number (MON),

is determined at 900 rpm engine speed instead of the 600 rpm for RON.[2] MON

testing uses a similar test engine to that used in RON testing, but with a preheated fuel mixture, higher engine speed, and variable ignition timing to

further stress the fuel's knock resistance. Depending on the composition of the fuel, the MON of a modern pump gasoline will be about 8 to 12 octane lower than the RON, but there is no direct link between RON and MON. Pump gasoline specifications typically require both a minimum RON and a minimum MON.

|

Ball-and-stick model of cyclobutane

|

In chemistry, an alkene is a hydrocarbon containing a carbon–carbon double bond.

Alkene is often used as synonym of olefin, that is, any hydrocarbon containing one or more double bonds.[2] Two general types of monoalkenes are distinguished: terminal and internal. Also called α-olefins, terminal alkenes are more useful.In organic

chemistry, an alkane, or paraffin (a historical trivial name that also has other meanings), is an acyclic saturated hydrocarbon. In other words, an alkane consists of hydrogen and carbon atoms arranged in a tree structure in which all the carbon–carbon bonds are single.

In organic

chemistry, the cycloalkanes (also

called naphthenes,

but distinct from naphthalene)

are the monocyclic saturated hydrocarbons.[1] In

other words, a cycloalkane consists only of hydrogen and carbon atoms

arranged in a structure containing a single ring (possibly with side chains),

and all of the carbon-carbon bonds are single.

The larger cycloalkanes, with more than 20 carbon atoms are typically called cycloparaffins.

All cycloalkanes are isomer of Alkene.

|

|

Reid vapor pressure (RVP)

is a common measure of the volatility of gasoline and

other petroleum products.It is defined as the absolute vapor pressure exerted by the vapor of the liquid and any dissolved gases/moisture at 37.8 °C (100 °F) as determined by the test method ASTM-D-323, which was first developed in 1930 and has been revised several times (the latest version is ASTM D323-15a).The

test method measures the vapor pressure of gasoline, volatile crude oil, jet fuels, naphtha, and other volatile petroleum products but is not applicable for liquefied petroleum gases.

RVP is commonly reported in kilopascals (kPa)

or pounds per square inch (psi) and

represents volatization at atmospheric pressure because ASTM-D-323 measures the gauge pressure of the sample in a non-evacuated chamber.

|

A drink is a form of liquid which has been prepared for human consumption. The preparation can include a number of different steps, some prior to transport, others immediately prior to consumption.

|

A drink (or beverage) is a liquid intended for human consumption. In addition to their basic function of satisfying thirst, drinks play important roles in human culture. Common types of drinks include plain drinking

water, milk, juice, smoothies and soft drinks. Traditionally warm beverages include coffee, tea,

and hot chocolate. Caffeinated drinks that contain the stimulant caffeine have a long history.

In addition, alcoholic drinks such as wine, beer, and liquor, which contain the drug ethanol, have been part of human

culture for more than 8,000 years. Non-alcoholic drinks often signify drinks that would normally contain alcohol, such as beer, wine and cocktails, but are made with a sufficiently low concentration of alcohol

by volume. The category includes drinks that have undergone an alcohol removal process such as non-alcoholic beers and de-alcoholized wines.

|

|

Beer measurement

When drinking beer,

there are many factors to be considered. Principal among them are bitterness, the variety of flavours present in the beverage and their intensity, alcohol content,

and colour. Standards for those characteristics allow a more objective and uniform determination to be made on the overall qualities of any beer.

"Degrees Lovibond" or "°L" scale is a measure of the colour of a substance, usually beer, whiskey,

or sugar solutions.

The determination of the degrees Lovibond takes place by comparing the colour of the substance to a series of amber to brown glass slides, usually by a colorimeter.

The scale was devised by Joseph Williams Lovibond. The Standard

Reference Method (SRM)

and European Brewery Convention (EBC)

methods have largely replaced it, with the SRM giving results approximately equal to the °L.

The Standard Reference Method or SRM[2] is a system modern brewers use to measure colour intensity, roughly darkness, of a beer or wort. The method involves the use of a spectrophotometer or

photometer to measure the attenuation of light of a particular wavelength, 430 nanometres (blue), as it passes through a sample contained in a cuvette of standardised dimensions located in the light path of the instrument.

The EBC convention also measures beer and wort colour, as well as quantifying turbidity (also known as haze) in beer.

|

The CQS generates the general index Qa. Several manufacturers are beginning to publish data on CQS scores of their products, including some who claim light sources with CQS scores up to 97.

|

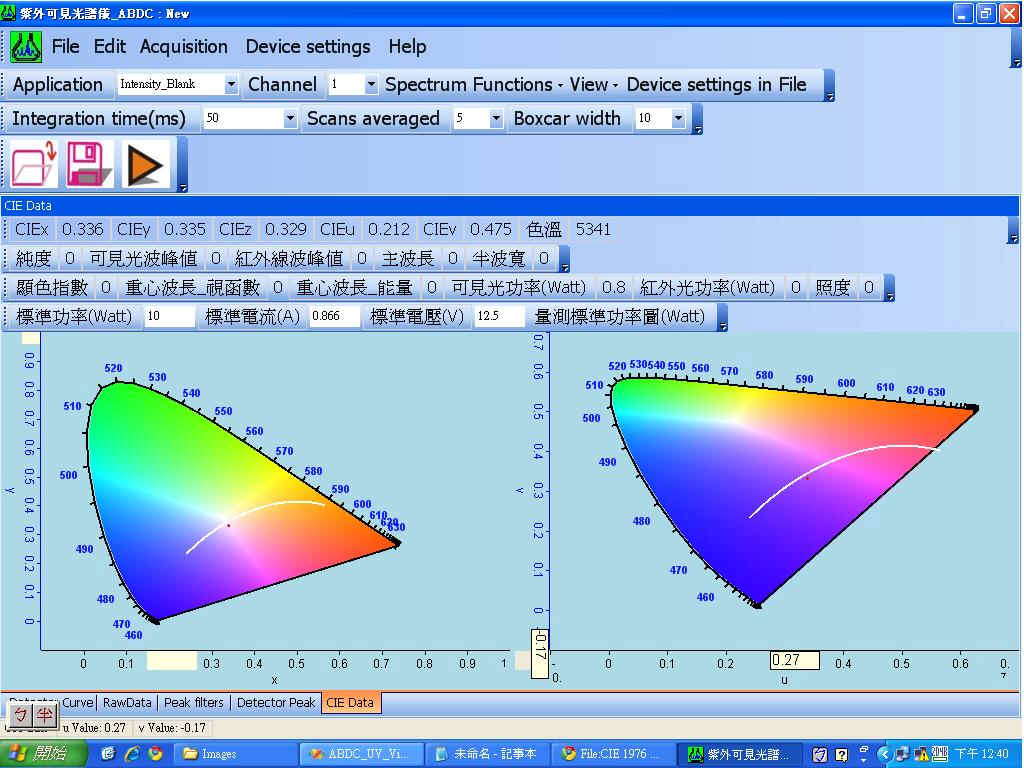

Color quality scale (CQS) is a color rendering score – a quantitative measure of the ability of a light source to reproduce colors of illuminated objects. Developed by researchers at NIST the

metric aims to overcome some of the issues inherent in the widely used color rendering index (CIE Ra, 1974).

- The color space used in CIE Ra is outdated and nonuniform, and CQS uses CIELAB as a replacement.

- The Von Kries chromatic adaptation transform used by Ra does not perform as well as other available models. CQS uses CMCCAT2000.

- CIE Ra is based on desaturated samples, and a lamp's performance in rendering these samples fideliously is not necessarily linked to how it may perform with samples of higher saturation. CQS uses higher saturation samples.

- ‘Pure’ fidelity (where all deviations are considered bad) does not account for desired chromaticity changes. Increased saturation might be preferred. CQS does not penalise against increases in saturation.

- In CIE Ra the arithmetic mean is taken of the color differences for the individual samples. In CQS the individual results are combined through a root mean square instead, so that a small number of poorly rendered objects reflects with greater strength in the overall result.

- Negative values of CQS are made impossible due to their potential for consumer confusion.

- CCTs of lower than 2800K are penalised so that the CQS is more representative of their actual color rendering as opposed to their fidelity.

|

list)

|

Cooking oil is plant, animal, or synthetic liquid fat used in frying, baking, and other types of cooking. It is also used in food preparation and flavoring not involving heat, such as salad dressings and bread dips, and may be called edible oil.

Cooking oil is typically a liquid at room temperature, although some oils that contain saturated fat, such as coconut oil, palm oil and palm kernel oil are solid.[1]

There are a wide variety of cooking oils from plant sources such as olive oil, palm oil, soybean oil, canola oil (rapeseed oil), corn

oil, peanut oil and other vegetable oils, as well as animal-based oils like butter and lard.

|

Sugar refinery in Groningen,

The Netherlands

|

A sugar refinery is a refinery which processes raw sugar from cane or beets into white

refined sugar.

Many cane sugar mills produce raw sugar, which is sugar that still contains molasses, giving it more colour (and impurities) than the white sugar which is normally consumed in households and used as an ingredient in soft drinks and foods. While cane sugar does not need refining to be palatable, sugar from sugar

beet is almost always refined to remove the strong, usually unwanted, taste of beets from it.[1] The refined sugar produced is more than 99 percent pure sucrose.

Many sugar mills only operate during the harvest season, whereas refineries may work the year round. Sugar beet refineries tend to have shorter periods when they process beet than cane refineries, but may store intermediate product and process it in the off-season. Raw sugar is either processed and sold locally, or is exported and refined elsewhere.

|

Paraffin wax is

mostly found as a white, odorless, tasteless, waxy solid, with a typical melting point between about 46 and 68 °C (115 and 154 °F),and a density of around 900 kg/m3.

|

Paraffin wax (or petroleum

wax) is a soft colorless solid derived from petroleum, coal or oil

shale that

consists of a mixture of hydrocarbon molecules

containing between twenty and forty carbon atoms. It is solid at room temperature and begins to melt above

approximately 37 °C (99 °F), and

its boiling point is above 370 °C (698 °F). Common

applications for paraffin wax include lubrication, electrical

insulation, and candles;[4] dyed

paraffin wax can be made into crayons.

It is distinct from kerosene and

other petroleum products that are sometimes called paraffin.

|

VI. Water Quality ( Pt - Co )

|

Raw water is water found in the environment that has not been treated and does not have any of its minerals, ions, particles, bacteria, or parasites removed. Raw water includes rainwater, ground water, water from infiltration wells, and water from bodies like lakes and rivers.

Raw water is generally unsafe for human consumption due to the presence of contaminants. A major health problem in some developing countries is use of raw water for drinking and cooking.

Without treatment, raw water can be used for irrigation, construction, or cleaning purposes. Farmers use it for watering their crops and give it to livestock to drink, storing it in man-made lakes or reservoirs for long periods of time. Construction industries can use raw water for

making cement or for damping down unsealed roads to prevent dust rising. Raw water can also be used for flushing toilets and washing cars, as well as any other purposes that do not require it to be consumed by humans. Water in this form is considered raw, as opposed to water which has been treated before consumption, such as drinking water or water which has been used in an industrial process, such as waste

water.

Raw water flushing is a method of water conservation where raw water is used for flush toilets.

|

Industrial wastewater, Leachate, Return flow, Surface runoff,

Urban runoff, Agricultural wastewater

|

Wastewater is generated after the use of fresh water in a variety of applications, and usually involves leaching, flushing, or washing away waste products and nutrients added to the water during these applications. A more detailed definition for wastewater is "Used water from any combination of domestic, industrial, commercial or agricultural activities, surface runoff / storm water, and any sewer inflow or sewer infiltration".

In everyday usage, wastewater is commonly a synonym for sewage (also called sewerage, domestic wastewater, or municipal wastewater), which is wastewater that is produced by a community of people. It is typically transported through a sewer system.

|

Key Words :

#PAT #NIR #FTIR #ATR #UV-VIS #UAN #DEF#AdBlue #DAP #BioDiesel #Lubricant #MON #RVP #Paraffin #PetroleumWax #Drink #Beverage #CookingOil#SugarRefinery #WaterQuality #Pt #Co #RawWater #Wastewater

|