|

Product Atlas (Product Catalogue)

Preparative Chromatography Systems DAC/M/HPLC/SAC/Gels |

|

Gelai Precision Instruments CO. LTD

Industrial development zone Dayi County,

Chengdu,

Sichuan P.R.China

86-28-88201801, 88201803

cdsglp@163.com

http://www.cdgelai.com/

International Marketing and Cooperation Division :

The Analytical Based Development Center (ABDC WorkShop)

5th Floor, NO.641, Fu

Shun Road, Shi-Tuen District , Taichung City, Taiwan, R.O.C.

886-4-24628085, FAX:886-4-22569743

service@chromnet.net

http://www.chromnet.net/ |

|

Contents: |

One.Company Overview

Two.Product Introduction

1.Semi-preparative/Preparative Liquid

Chromatography system

1-1.GL3000-50ml system

(recommended column:

SAC25.4/41.4)

1-2.GL3000-100ml system

(recommended column:

SAC 50/77)

1-3.GL3000-250ml system

(recommended column:

SAC80/100)

2.Pilot scale

Preparative Liquid Chromatography system

2-1.GL3000-500ml system (recommended column:

DAC100)

2-2.GL3000-1L system (recommended column:

DAC150)

2-3.GL3000-2L system (recommended column:

DAC200)

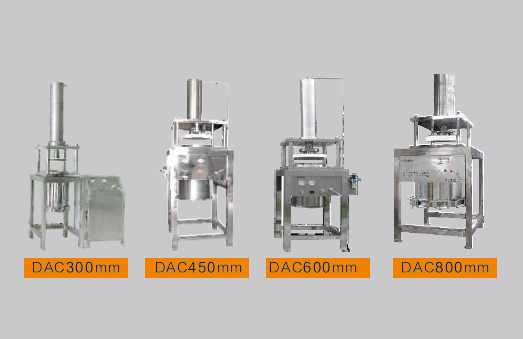

3.The

Industrial-scale Preparative Liquid Chromatography system

3-1.GL3000-3 L system (recommended column:

DAC300)

3-2.GL3000-5 L system (recommended column:

DAC450)

3-3.GL3000-10L system (recommended column:

DAC600)

3-4.GL3000-20L system (recommended column:

DAC800)

3-5.GL3000-30L system (recommended column:

DAC1000)

4.Common spare and

service parts

Three.Sample

separation service

Four.Customer Examples

|

|

|

One. Company Overview

Leading with the Quality, Performance and Cost !

We(Gelai_ABDC)are a

global technology and marketing team, with continuous efforts for more than 20

years, cooperating seamlessly with all users in research institutions, industry,

universities, for their practical demands, and successfully developed DAC M/HPLC

systems with independent intellectual properties.

http://www.cdgelai.com/

http://www.chromnet.net/

|

|

1.

More than>400

large systems installed, with abundant high throughput, high

efficiency large-scale DAC-HPLC experiences for more than 13 years.

|

|

|

|

2. Dedicated optimized Dynamic Axial Compression Column(DAC Column) design, approaching

high resolution from the analytical HPLC column.

|

|

|

|

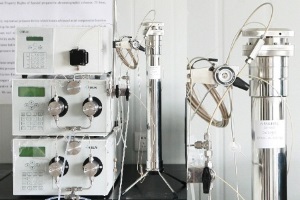

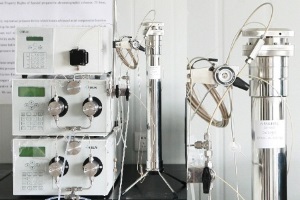

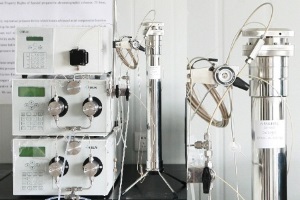

3.

Middle/High pressure

Gradient

Pump(M/HPLC Pumps) capability, with

precision screw module that promises very stable & precise mobile phase output.

|

|

|

|

4. 1/2 to 2/3

cost, very helpful to optimized budgets controls, especially for cost management

for acquiring more equipment. |

|

Through years of unremitting hard work, and relying on the cooperation with scientific

research academies such as local military industry as well as colleges and

universities, we have successfully launched a series of products such as:

Static

Axial Compression Column(SAC), with diameters from 25.4mm to 100mm,

Dynamic Axial Compression(DAC) Column,

from

80mm to 1200mm,

Preparative HPLC/MPLC pumps, from

50ml/min to 30L/min, and

Ultraviolet

detector, Fraction Collector, etc.,

with independent intellectual property rights and providing a complete set of

Preparative Chromatogram Systems from lab test to large industrial production

scales.

With international advanced technologies and leading designs, our products keep

at advanced performances among similar products.

Our products also have already been awarded honor and utility model

patents and are widely applied in separation and purification of natural and

plant product, synthetic medicine, protein and polypeptide, etc.

We combine the capabilities to keep key technology

innovations and to keep our users with cost advantage as much as possible, while

persist our product with highest qualities, services, including the compliances

of the ISO9001:2000 quality assurance system to take strict testing methods,

that guarantee our qualified products with full in line with the standards such

as GMP and FDA.

By regular technology trainings, we provide our clients with integrated reliable

products and before-sales and after-sales services, ranging from technical

consultation, system evaluation, sample testing and separation method

development, system installation, onsite operation training, system IQ/OQ

validation for certification, process amplification, and to extended application

developments.

As a professional manufacturer of Preparative Chromatogram Systems, with the

experiences in equipment manufacturing and client support, the

Gelai_ABDC provides guarantees to clients in terms of increasing

productivities, minimized equipment repair, and quickening investment returns.

We are making prominent global contributions with our constantly providing of

excellent preparative chromatogram system, fluid transmission equipment and

service.

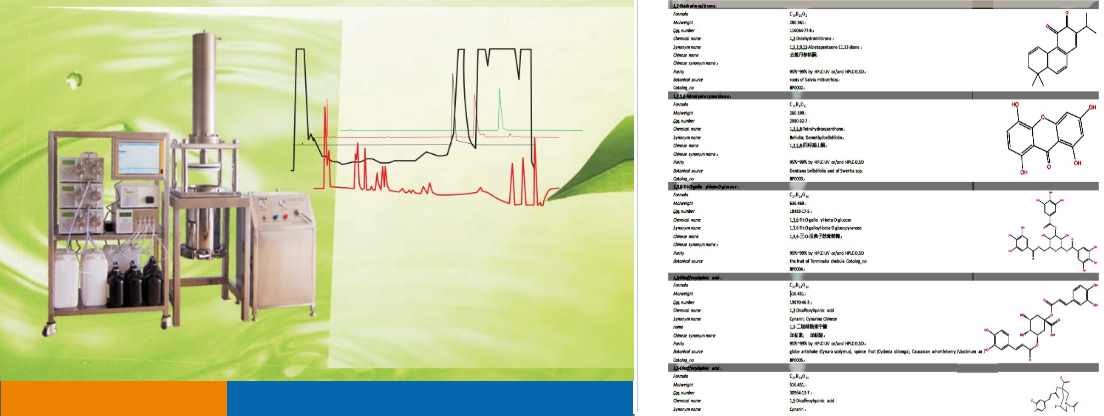

Two. Product Introduction:

1.

Semi-preparative / Preparative Liquid Chromatography system

System Overview:

The Semi-prep / preparative liquid chromatography system may be equipped with

50, 100, or 250ml/min maximum flow rates pump head, with mixer, UV detector,

online filters, injection valve or sample injection pump, chromatographic work

station software, and may be configured with 25.4mm, 41.4mm, 50mm, 77mm, 80mm,

100mm ID pre-packed columns.

The semi-preparative / preparative liquid chromatography systems can be used in

normal phase, reverse phase, Ion exchange chromatography and other modes by the

selections of different types of packing materials, and are suitable for

small-scale purification and separation for milligram to gram sample sizes in

the research institutions and laboratories.

They are common for purifications of small amount of standards and standard

of impurities.

System parameters:

Hex={FF,D6,97}

|

|

Pump |

Infusion mode

|

Screw drive parallel twin piston

reciprocating pump, double piston pipette |

|

|

Pump Material

|

316L stainless steel / PEEK /

Titanium |

|

|

Maximum operating pressure

|

6000Psi |

|

|

Flow accuracy

|

± 1% |

|

|

Flow repeatability |

RSD≤0.5%

|

|

|

|

|

|

|

|

Detector |

Wavelength |

190-740nm

|

|

|

Cut Off Filter |

370nm

|

|

|

Light source |

Deuterium lamp, Halogen tungsten

lamp (optional)

|

|

|

Band width |

8nm |

|

|

Wavelength precision |

±1nm

|

|

|

Noise |

2*10-5AU (254nm@1ml/min @methanol)

|

|

|

Drift

|

5*10-5AU/h (254nm@1ml/min @methanol)

|

|

|

Minimum testing conc. |

5*10-9g/ml(254nm@1ml/min@methanol@Naphthalene standard)

|

|

|

Testing range

|

0~2.5AU |

|

|

|

|

|

|

|

Columns |

Sieve aperture

|

3-5um

|

|

|

|

Column Material

|

316L stainless steel

|

|

|

|

Distributor

|

Multi-point distribution tech (our

patent)

|

|

|

|

Inner wall surface finish/roughness |

≤0.1μm

|

|

|

1-1. GL3000-50ml system

(recommended column: SAC25.4/41.4) |

|

|

|

Code

|

Remarks

|

Number

|

|

|

GL3000-50-01 |

GL3000-50ml/min Preparative high pressure pump

|

2 |

|

|

GL3000-50-02 |

UV-3292 UV/VIS detector

|

1 |

|

|

GL3000-50-03 |

Preparative flow cell

|

1 |

|

|

GL3000-50-04 |

Preparative columns GL-ID25.4mm * 450mm

|

1 |

|

|

GL3000-50-05 |

Preparative columns GL-ID41.4mm * 450mm (optional)

|

1 |

|

|

GL3000-50-06 |

Parts for 3725i-038 manual injection valve

|

1 |

|

|

GL3000-50-07 |

10ml Sample loop

|

1 |

|

|

GL3000-50-08 |

GL3000-50ml Sample loading pump (optional)

|

1 |

|

|

GL3000-50-09 |

Fraction collector(optional, Valve/XY)

|

|

|

|

GL3000-50-10 |

GL3000 chromatography workstation software

|

1 |

|

|

GL3000-50-11 |

GL3000-20 on-line filter

|

1 |

|

|

GL3000-50-12 |

Tool kit

|

1 |

|

|

GL3000-50-13 |

Other |

1 |

|

|

1-2. GL3000-100ml system

(recommended column:

SAC50/77) |

|

|

|

Code

|

Remarks

|

Number

|

|

|

GL3000-100-01 |

GL3000-100ml/min Preparative high pressure pump

|

2 |

|

|

GL3000-100-02 |

UV-3292 UV/VIS detector

|

1 |

|

|

GL3000-100-03 |

Preparative flow cell

|

1 |

|

|

GL3000-100-04 |

Preparative columns GL-ID50mm * 450mm

|

1 |

|

|

GL3000-100-05 |

Preparative columns GL-ID77mm * 450mm (optional)

|

1 |

|

|

GL3000-100-06 |

Parts for 3725i-038 manual injection valve

|

1 |

|

|

GL3000-100-07 |

20ml Sample loop

|

1 |

|

|

GL3000-100-08 |

GL3000-100ml Sample loading pump (optional)

|

1 |

|

|

GL3000-100-09 |

Fraction collector(optional, Valve/XY)

|

1 |

|

|

GL3000-100-10 |

GL3000 chromatography workstation software

|

1 |

|

|

GL3000-100-11 |

GL3000-20 on-line filter

|

1 |

|

|

GL3000-100-12 |

Tool kit

|

|

|

|

GL3000-100-13 |

Other |

1 |

|

|

1-2. GL3000-250ml system

(recommended column:

SAC80/100) |

|

|

|

Code

|

Remarks

|

Number

|

|

|

GL3000-250-01 |

GL3000-250ml/min Preparative high pressure pump

|

2 |

|

|

GL3000-250-02 |

UV-3292 UV/VIS detector

|

1 |

|

|

GL3000-250-03 |

Preparative flow cell

|

1 |

|

|

GL3000-250-04 |

Preparative columns GL-ID80mm * 450mm

|

1 |

|

|

GL3000-250-05 |

Preparative columns GL-ID100mm * 450mm (optional)

|

1 |

|

|

GL3000-250-06 |

Parts for 3725i-038 manual injection valve

|

1 |

|

|

GL3000-250-07 |

20ml Sample loop

|

1 |

|

|

GL3000-250-08 |

GL3000-100ml Sample loading pump (optional)

|

1 |

|

|

GL3000-250-09 |

Fraction collector(optional, Valve/XY)

|

1 |

|

|

GL3000-250-10 |

GL3000 chromatography workstation software

|

|

|

|

GL3000-250-11 |

GL3000-20 on-line filter

|

1 |

|

|

GL3000-250-12 |

Tool kit

|

1 |

|

|

GL3000-250-13 |

Other |

1 |

Modules introductions:

|

|

GL3000- Preparative high

pressure pump Features:

(50mL/min, 100mL/min, 250mL/min) |

|

|

|

1. Using the latest 32-bit RISC central ultra- high speed computing and 32 bit

DSP stepping drive control processors for core control. |

|

|

2. It is based on all digital frequency-based systems, advanced motor drive system and

friendly user display interface, making operation and control of the device more

convenient. |

|

|

3. Dual screw dual piston control, with the pump can be configured to isocratic, gradient

mode. |

|

|

4. High-precision screw drive model with high flow rate precision, good system

reproducibility and very low flow pulse features. |

|

|

5. Advanced pump head and check valve design ideas, a unique blend of the world's most

advanced experiences, allowing our users to guarantee the flow rate accuracy and

reproducibility specifications in various conditions. |

|

|

6. When working on the preparative high-pressure gradient mode, the

PC/Master module can control more than

one pumps of the same type, and can monitor gradient curve gradient method

through the PC/Master for verifications. |

|

|

7. A variety of communication modes, standard RS232, RS485, Ethernet interface, are selectable

for the preparative high-pressure pump control, which has greater advantages for

high purity sample preparation of

requirements. |

Technical specifications:

|

|

Stream infusion type |

Dual piston elution. |

|

|

Pump head material |

316L Stainless Steel/Other options |

|

|

Maximum operating pressure |

50 mL/min pump head: 6000Psi(420 Kgf/cm2, Bar)

100mL/min pump head: 5000psi(350 Kgf/cm2, Bar)

250mL/min pump head: 5000psi(350 Kgf/cm2, Bar) |

|

|

Flow rate range |

50mL/min pump head: 1-50mL/min

100mL/min pump head: 1-100mL/min

250mL/min pump head: 1-250mL/min |

|

|

Flow rate accuracy |

±1%, @1-99% flow rate range & MeOH: H2O (80%: 20)

|

|

|

Flow repeatability

|

RSD ≤1%

|

|

|

Display

|

192 × 64 pixels LCD screen |

|

|

System Protection |

Slow start and stop, auto-stop maximum pressure setting, data auto-stored

|

|

|

System Connection |

1/4 or 1/8 tubing connections |

|

|

Control |

Multiple communication modes, standard RS232, RS485, Ethernet interface for

high-pressure infusion pump control |

|

|

Power supply |

220V ± 10%, 50Hz, 400W |

|

|

Dimensions |

580mm × 360mm × 210mm (Length × Width × Height) |

|

|

Transmission type |

Precision dual-actuators precision ball screw drive that is produced by the

HIWIN (Taiwan) with high precision, small pulses, good performance. Our pressure

can be displayed in bar that may sense to our very small pressure fluctuations

within 2bar. |

|

|

UV3292 SpectroDetector Features:

|

|

|

|

1. Adopt all digital output design. After its signal is through 24 bit A/D, the

single-chip microcomputer finishes the process of data conversion and zero

setting, and the processed result will get the RS 232 interface. |

|

|

2. The gratting, directly fixed on the motor shaft of stepping motor, through

the procedure of single-chip microcomputer to take sine conversion, can control

the motor to choose the wavelength.Replace the traditional sine bar

organization, and further improve the reliability and stability of the system;

wavelength can be corrected once the system is started.

|

|

|

3. Programming control to wavelength. |

|

|

4. Flow-stopped automatic spectral scanning |

|

|

5. Flow cell has the "Z" style design and is processed by thermostatically

processing so that the noise and drift of equipment can be improved to the large

extent.

|

|

|

6. Light path is designed of double light beam so as to further minimize

drifting impact from the surrounding change.

|

|

|

7. Optical path can be adjusted through replacing flow cell and changing

corresponding system parameters, so it can be transferred from analytical style

to semi preparative and even to big preparative style easily. |

|

|

8. The simulative analog output port is equipped.

|

|

|

9. It can be controlled through RS-232 interface by chromatographic work

station. |

|

|

|

Technical specifications:

|

|

Wavelength range |

190~740nm |

|

|

Edge filter |

370nm

|

|

|

Light source |

Deuterium lamp, halogen tungsten lamp (optional) |

|

|

Band width |

8nm |

|

|

Wavelength precision |

±1nm |

|

|

Noise |

2*10-5AU (254nm@1ml/min @methanol)

|

|

|

Drift |

15*10-5AU/h 254nm@1ml/min @methanol)

|

|

|

Minimum testing concentration |

5*10-9g/ml (254nm@1ml/min@methanol@Naphthalene standard) |

|

|

Testing range |

0~2.5AU |

|

|

Display LCD |

2*16 English

|

|

|

GLP information |

working time of light source, times of light kindled

|

|

|

Dimension |

4600mm*330mm*180mm |

|

|

Static Axial Compression Column

Features:

(SAC Column Refillable Prepacked columns) |

|

|

|

1. Global leading design and approach for the embedded manual pressing device

that performs advanced axial compression functionality. |

|

|

2. The Surface Finish of our column wall is better than ≥ ▽ 12 (ie, Ra ≤ 0.25μm)

that ensuring very good column concentricity(0.2μm), and is better than similar

global products. We continuously and routinely cooperate with domestic and

global institutions for advanced technologies, such as the concentricity and

precision polishing technologies for column inner wall from key military units.

These efforts ensures out excellent product stability and performance.

|

|

|

3. Maintains sufficient high internal pressure that prevent the sharp decline in

column efficiency caused by the collapsing of column bed. In long term usages if

the column bed have loosed and collapsed, the original column pressure and

column efficiency can be restored without any tools by just manually and gently

twist on the top pressing device.

|

|

|

4. The column efficiency is high enough to makes it easy to achieve linear

amplification from analytical to preparation scales. The unique column-end

distribution piece design, have provided more uniform chromatographic process

for samples, with more symmetrical peak shapes.

|

|

|

5. With removable and both normal and reverse directions applicable

feasibilities that make user re-filling very easy. The durable life time is much

longer than other prepared column that are implemented with fixed flange sealing

mounting.

|

|

NOTE: We can also, according to customer requirements, manufacture customized or

specialized columns that are packed with user specified packings from various

sources as Kromasil, HyperSil, Fuji, etc. We also provide re-packing and other

services for preparative columns provided from customers. |

Routine specifications:

|

|

1.

|

ID25.4mm *450mm(1 inch)

|

|

|

|

2.

|

ID41.4mm *450mm(2 inch) |

|

|

3. |

ID50mm *450mm

|

|

|

4.

|

ID77mm *450mm(3 inch)

|

|

|

5.

|

ID80mm *450mm

|

|

|

6.

|

ID100mm *450mm

|

|

|

7.

|

Customized sizes & packing |

|

|

Fraction collector Features:

(Valve 1In-7Out / XY24,48,96 wells) |

|

|

|

1. Automatic fraction collector has an all-digital design, whose signal is

processed by PLC and then the results will reach the RS232/485 interface. |

|

|

2. The equipment has programming control, combining with chromatograph can

finish the collection easily. |

|

|

3. The change of every peak is monitored with controlled collections by

chromatographic work station.

|

|

|

4. Both Valve-Switching and X-Y Movement types are available. 4. One collection

position is open all the time for and the others can be switched freely. |

|

|

5. Buttons on the front panel are can also be easily manual operated for peak

collections.

|

Technical specifications:

|

|

Channels(Valve type, GL-LF08-Valve) |

1 input

to 7 output channels

|

|

|

Number of Fractions

(X-Y type, GL-LF08-XY):

|

96, 48, 24 wells |

|

|

Collection Tube Volumes(X-Y type, GL-LF08-XY) |

50mL/96wells, 100mL/48wells, large volumes/24wells

|

|

|

Temperature control |

Room temperature, or optional for 2-8 degrees(C) |

|

|

Fraction Modes |

Manual or programmed fraction collection by peak slope, level, and time bands. |

|

|

Control |

PLC programmable control protocol. |

|

|

GL3000 Preparative Chromatography Workstation software Features: |

|

|

|

Chromatographic work station, matched with chromatograph, is the computer system

that can process chromatograph signal to be data.

The software focuses on intelligent process for spectrogram data, tries to

minimize the process knowledge of spectrogram data which should be mastered by

users, and transfers the knowledge to be clear and easy for users to understand,

so users will not see those baffling parameters in the chromatographic data

processor, (such as “Peak starting slope”, “parameter changing time”, “baseline

drift”, etc.)

It has overall professional functions, and when some special processing effect

is needed, there are still some simple and convenient adjustment methods.

Meanwhile, this software pursues succinct and compact interface layout, and

offers some functions like federated calculation, print by batch, result

summarizing, coherent operation, automatic save, and spectrogram management to

enhance daily analytical efficiency.

The above aspects mentioned make this software rich in function and convenient

in operation.

Another

distinguished characteristic of this software is that the close combination with

Microsoft office, like how to create analytical report in WORD, quantitative

result (or collection of several times’ quantitative results) which can be

delivered to EXCEL through clipping board, and

analytical records which can be saved in ACCESS database directly, etc.

When preparative chromatograph is put to use in

production, manual short line and notes can be generated on peak at any time.

|

|

|

|

|

|

|

2.Pilot scale Preparative Liquid Chromatography system

System Overview:

Based on pilot scales,

the system is equipped with suitable module, including GL3000-500ml, GL3000-1L,

and GL3000-2L pumps, matched UV detector, mixer, and line filters.

The ID100mm, ID150mm, and ID200mmDAC (Dynamic axial compression column) systems

are recommended respectively.

The chromatography workstation is built-in.

The Autosampler, automatic Fraction collector, pumps, system framework and

embedded Industrial PC, etc. could be optionally added into integrated

configurations. Suitable for normal phase, reverse phase, ion-exchange In other

various chromatographic mode, suitable separation of products from gram to

hundreds of grams. .

System parameters:

Hex={FF,D6,97}

|

|

Pump |

Infusion mode

|

Screw drive parallel twin piston

reciprocating pump, double piston pipette |

|

|

Pump Material

|

316L stainless steel / PEEK /

Titanium |

|

|

Maximum operating pressure

|

6000Psi |

|

|

Flow accuracy

|

± 1% |

|

|

Flow repeatability |

RSD≤0.5%

|

|

|

|

|

|

|

|

Detector |

Wavelength |

190-740nm

|

|

|

Cut Off Filter |

370nm

|

|

|

Light source |

Deuterium lamp, Halogen tungsten

lamp (optional)

|

|

|

Band width |

8nm |

|

|

Wavelength precision |

±1nm

|

|

|

Noise |

2*10-5AU (254nm@1ml/min @methanol)

|

|

|

Drift

|

5*10-5AU/h (254nm@1ml/min @methanol)

|

|

|

Minimum testing conc. |

5*10-9g/ml(254nm@1ml/min@methanol@Naphthalene standard)

|

|

|

Testing range

|

0~2.5AU |

|

|

|

|

|

|

|

Columns |

Sieve aperture

|

3-5um

|

|

|

|

Column Material

|

316L stainless steel

|

|

|

|

Distributor

|

Multi-point distribution tech (our

patent)

|

|

|

|

Inner wall surface finish/roughness |

≤0.1μm

|

|

|

2-1. GL3000-500ml system

(recommended column: DAC100) |

|

|

|

Code

|

Remarks

|

Number

|

|

|

GL3000-500-01 |

GL3000-500ml/min Preparative high pressure pump for mobile phase streams |

2 |

|

|

GL3000-500-02 |

GL3000-500ml/min Preparative high pressure pump for Sample loading or mobile

phase streams |

1 |

|

|

GL3000-500-03 |

UV-3292 UV/VIS detector

|

1 |

|

|

GL3000-500-04 |

Preparative flow cell |

1 |

|

|

GL3000-500-05 |

Preparative DAC column, ID100mm

|

1 |

|

|

GL3000-500-06 |

Dynamic mixer(DT optional)

|

1 |

|

|

GL3000-500-07 |

Fraction collector(optional, Valve/XY)

|

1 |

|

|

GL3000-500-08 |

Online Filter(optional, GL50)

|

1 |

|

|

GL3000-500-09 |

Equipment Framework(optional)

|

1 |

|

|

GL3000-500-010 |

Embedded Industrial PC |

|

|

|

GL3000-500-011 |

GL3000 chromatography workstation software |

1 |

|

|

GL3000-500-012 |

Dedicated Tool kit |

1 |

|

|

GL3000-500-013 |

Installation Startup Kit

|

1 |

|

|

GL3000-500-014 |

Others |

1 |

|

|

2-2. GL3000-1L system

(recommended column: DAC150) |

|

|

|

Code

|

Remarks

|

Number

|

|

|

GL3000-1L-01 |

GL3000-1L/min Preparative high pressure pump for mobile phase streams |

2 |

|

|

GL3000-1L-02 |

GL3000-1Lmin Preparative high pressure pump for Sample loading or mobile phase streams |

1 |

|

|

GL3000-1L-03 |

UV-3292 UV/VIS detector

|

1 |

|

|

GL3000-1L-04 |

Preparative flow cell |

1 |

|

|

GL3000-1L-05 |

Preparative DAC column, ID150mm

|

1 |

|

|

GL3000-1L-06 |

Dynamic mixer(DT optional)

|

1 |

|

|

GL3000-1L-07 |

Fraction collector(optional, Valve/XY)

|

1 |

|

|

GL3000-1L-08 |

Online Filter(optional, GL50)

|

1 |

|

|

GL3000-1L-09 |

Equipment Framework(optional)

|

1 |

|

|

GL3000-1L-010 |

Embedded Industrial PC |

1 |

|

|

GL3000-1L-011 |

GL3000 chromatography workstation software |

1 |

|

|

GL3000-1L-012 |

Dedicated Tool kit |

1 |

|

|

GL3000-1L-013 |

Installation Startup Kit

|

1 |

|

|

GL3000-1L-014 |

Others |

1 |

|

|

2-3. GL3000-2L system

(recommended column: DAC200) |

|

|

|

Code

|

Remarks

|

Number

|

|

|

GL3000-2L-01 |

GL3000-2L/min Preparative high pressure pump for mobile phase streams |

2 |

|

|

GL3000-2L-02 |

GL3000-2L/min Preparative high pressure pump for Sample loading or mobile phase

streams |

1 |

|

|

GL3000-2L-03 |

UV-3292 UV/VIS detector

|

1 |

|

|

GL3000-2L-04 |

Preparative flow cell |

1 |

|

|

GL3000-2L-05 |

Preparative DAC column, ID200mm

|

1 |

|

|

GL3000-2L-06 |

Dynamic mixer(DT optional)

|

1 |

|

|

GL3000-2L-07 |

Fraction collector(optional, Valve/XY)

|

1 |

|

|

GL3000-2L-08 |

Online Filter(optional, GL50)

|

1 |

|

|

GL3000-2L-09 |

Equipment Framework(optional)

|

1 |

|

|

GL3000-2L-010 |

Embedded Industrial PC |

1 |

|

|

GL3000-2L-011 |

GL3000 chromatography workstation software |

1 |

|

|

GL3000-2L-012 |

Dedicated Tool kit |

1 |

|

|

GL3000-2L-013 |

Installation Startup Kit

|

1 |

|

|

GL3000-2L-014 |

Others |

1 |

Modules introductions:

|

|

GL3000- Preparative high pressure pump Features:

(500mL/min, 1L/min, 2L/min) |

|

|

|

1. Using the latest 32-bit RISC central ultra- high speed computing and 32 bit

DSP stepping drive control processors for core control. |

|

|

2. It is based on all digital frequency-based systems, advanced motor drive system and

friendly user display interface, making operation and control of the device more

convenient. |

|

|

3. Dual screw dual piston control, with the pump can be configured to isocratic, gradient

mode. |

|

|

4. High-precision screw drive model with high flow rate precision, good system

reproducibility and very low flow pulse features. |

|

|

5. Advanced pump head and check valve design ideas, a unique blend of the world's most

advanced experiences, allowing our users to guarantee the flow rate accuracy and

reproducibility specifications in various conditions. |

|

|

6. When working on the preparative high-pressure gradient mode, the

PC/Master module can control more than

one pumps of the same type, and can monitor gradient curve gradient method

through the PC/Master for verifications. |

|

|

7. A variety of communication modes, standard RS232, RS485, Ethernet interface, are selectable

for the preparative high-pressure pump control, which has greater advantages for

high purity sample preparation of

requirements. |

Technical specifications:

|

|

Stream infusion type |

Dual piston elution. |

|

|

Pump head material |

316L Stainless Steel/Other options |

|

|

Maximum operating pressure |

500

mL/min pump head: 3000Psi(210 Kgf/cm2, Bar)

1L/min pump head: 2000psi(140 Kgf/cm2, Bar)

2L/min pump head: 1500psi(105 Kgf/cm2, Bar) |

|

|

Flow rate range |

500mL/min pump head: 1-500mL/min

1L/min pump head: 0-1Lmin

2L/min pump head: 0-2Lmin |

|

|

Flow rate accuracy |

±1%, @1-99% flow rate range & MeOH: H2O (80%: 20)

|

|

|

Flow repeatability

|

RSD ≤1%

|

|

|

Display

|

192 × 64 pixels LCD screen |

|

|

System Protection |

Slow start and stop, auto-stop maximum pressure setting, data auto-stored

|

|

|

System Connection |

1/4 or 1/8 tubing connections |

|

|

Control |

Multiple communication modes, standard RS232, RS485, Ethernet interface for

high-pressure infusion pump control |

|

|

Power supply |

220V ± 10%, 50Hz, 400W |

|

|

Dimensions |

580mm × 360mm × 210mm (Length × Width × Height) |

|

|

Transmission type |

Precision dual-actuators precision ball screw drive that is produced by the

HIWIN (Taiwan) with high precision, small pulses, good performance. Our pressure

can be displayed in bar that may sense to our very small pressure fluctuations

within 2bar. |

|

|

UV3292 SpectroDetector Features: |

|

|

|

1. Adopt all digital output design. After its signal is through 24 bit A/D, the

single-chip microcomputer finishes the process of data conversion and zero

setting, and the processed result will get the RS 232 interface. |

|

|

2. The gratting, directly fixed on the motor shaft of stepping motor, through

the procedure of single-chip microcomputer to take sine conversion, can control

the motor to choose the wavelength.Replace the traditional sine bar

organization, and further improve the reliability and stability of the system;

wavelength can be corrected once the system is started.

|

|

|

3. Programming control to wavelength. |

|

|

4. Flow-stopped automatic spectral scanning |

|

|

5. Flow cell has the "Z" style design and is processed by thermostatically

processing so that the noise and drift of equipment can be improved to the large

extent.

|

|

|

6. Light path is designed of double light beam so as to further minimize

drifting impact from the surrounding change.

|

|

|

7. Optical path can be adjusted through replacing flow cell and changing

corresponding system parameters, so it can be transferred from analytical style

to semi preparative and even to big preparative style easily. |

|

|

8. The simulative analog output port is equipped.

|

|

|

9. It can be controlled through RS-232 interface by chromatographic work

station. |

Technical specifications:

|

|

Wavelength range |

190~740nm |

|

|

Edge filter |

370nm

|

|

|

Light source |

Deuterium lamp, halogen tungsten lamp (optional) |

|

|

Band width |

8nm |

|

|

Wavelength precision |

±1nm |

|

|

Noise |

2*10-5AU (254nm@1ml/min @methanol)

|

|

|

Drift |

15*10-5AU/h 254nm@1ml/min @methanol)

|

|

|

Minimum testing concentration |

5*10-9g/ml (254nm@1ml/min@methanol@Naphthalene standard) |

|

|

Testing range |

0~2.5AU |

|

|

Display LCD |

2*16 English

|

|

|

GLP information |

working time of light source, times of light kindled

|

|

|

Dimension |

4600mm*330mm*180mm |

|

|

Dynamic Axial Compression Column Features:

(DAC Column) |

|

|

|

The DAC Summary:

It is the only one technology that is universally

recognizedto be able to maintain good separation effect under various column

chromatography scales, and it is also the best column packing technology in the

preparative chromatographic field,

The advanced DAC(Dynamic axial compression column) have its own functions, as

self-packing, column pressure maintain, and self-release-packing.

The DAC packed column bed fully meets the continuity, uniformity, stability, and

tightness requirements.

The mechanism of DAC column is through the up and down movement of the piston to

pack, maintain column pressure and release packing.

The piston surrounding is equipped with a specially designed seal rings that

allow the piston to freely slide up and down, while maintaining high sealing

pressure . Piston motion and pressure is maintained by the uniform and stable

hydraulic pressure.

The separation effects of DAC columns with various diameters approach or even

equivalent to the analytical column.

|

|

|

Performance & Features: |

|

|

|

1 |

Adopt advanced structure design, flexible and convenient operation, small volume

and good appearance. |

|

2 |

The packing material filling process is easy to learn, the packing time is

short, with low supported compressed air requirement, that just 6kg air pressure

is sufficient for up to 90 kg packing pressure within the column. The column

performance is nearly close to that of analytical column.

|

|

3 |

DAC tech can pressurize the chromatographic column bed constantly, and

effectively avoid the collapse of column head and loose column bed. |

|

4 |

Pressure endurance, Adhesiveness: the inner surface finish of ≥ ▽ 12, namely,

the surface roughness ≤0.25μm; concentricity between column head and cylinder

reaches 0.2um, column head sealing is made of imported oblique seals spring

seals, that make the column with high pressure endurance to 6000psi without

leakage and 50 times of refilling without wear. |

|

5 |

The distribution uniformity and reproducibility: column head, column bottom are

equipped with multi-point distribution technology components(our patent), that

will enable product solution and mobile phase to uniformly flush through the

column cylinder, with good peak symmetry. 6.Long service time. Once

chromatographic column is polluted, to discharg packing and then re-packing is

very easy and convenient. Pepeatly re-packing is also possible, which largely

prolongs the service life of chromatographic column.

|

|

6 |

Long service time. Once chromatographic column is polluted, to discharg packing

and then re-packing is very easy and convenient. Pepeatly re-packing is also

possible, which largely prolongs the service life of chromatographic column. |

|

7 |

The same packing system supports the filling of various specifications of columns whose inner diameter are less than

or equal to those of DAC dynamic axial compression columns.

|

|

8 |

The packed chromatographic column can be separated from packing system and be

used independently. Moreover, the stability of column bed and original column

performance can also be kept, and it is convenient to move to use. |

|

9 |

Adopt overpressure protection to guarantee the users' safety completely.

10.Sales price is only one third of or even lower than the similar imported

products. |

|

10 |

Sales price is only one third of or even lower than the similar imported

products |

|

|

|

Fraction collector Features:

(Valve 1In-7Out / XY24,48,96 wells) |

|

|

|

1. Automatic fraction collector has an all-digital design, whose signal is

processed by PLC and then the results will reach the RS232/485 interface. |

|

|

2. The equipment has programming control, combining with chromatograph can

finish the collection easily. |

|

|

3. The change of every peak is monitored with controlled collections by

chromatographic work station.

|

|

|

4. Both Valve-Switching and X-Y Movement types are available. 4. One collection

position is open all the time for and the others can be switched freely. |

|

|

5. Buttons on the front panel are can also be easily manual operated for peak

collections.

|

Technical specifications:

|

|

Channels(Valve type, GL-LF08-Valve) |

1 input

to 7 output channels

|

|

|

Number of Fractions

(X-Y type, GL-LF08-XY):

|

96, 48, 24 wells |

|

|

Collection Tube Volumes(X-Y type, GL-LF08-XY) |

50mL/96wells, 100mL/48wells, large volumes/24wells

|

|

|

Temperature control |

Room temperature, or optional for 2-8 degrees(C) |

|

|

Fraction Modes |

Manual or programmed fraction collection by peak slope, level, and time bands. |

|

|

Control |

PLC programmable control protocol. |

|

|

GL3000 Preparative Chromatography Workstation software Features: |

|

|

|

Chromatographic work station, matched with chromatograph, is the computer system

that can process chromatograph signal to be data.

The software focuses on intelligent process for spectrogram data, tries to

minimize the process knowledge of spectrogram data which should be mastered by

users, and transfers the knowledge to be clear and easy for users to understand,

so users will not see those baffling parameters in the chromatographic data

processor, (such as “Peak starting slope”, “parameter changing time”, “baseline

drift”, etc.)

It has overall professional functions, and when some special processing effect

is needed, there are still some simple and convenient adjustment methods.

Meanwhile, this software pursues succinct and compact interface layout, and

offers some functions like federated calculation, print by batch, result

summarizing, coherent operation, automatic save, and spectrogram management to

enhance daily analytical efficiency.

The above aspects mentioned make this software rich in function and convenient

in operation.

Another

distinguished characteristic of this software is that the close combination with

Microsoft office, like how to create analytical report in WORD, quantitative

result (or collection of several times’ quantitative results) which can be

delivered to EXCEL through clipping board, and

analytical records which can be saved in ACCESS database directly, etc.

When preparative chromatograph is put to use in

production, manual short line and notes can be generated on peak at any time.

|

|

|

|

3.The Industrial-scale Preparative Liquid Chromatography system.

System Overview:

In accordance with the

scale of industrial production, the system is equipped with GL3000-3L,

GL3000-5L, GL3000-10L, GL3000-20L, or GL3000-30L pump, and UV detector, on-line

mixer, on-line filters and chromatography workstation.

Recommended with ID300mm, ID450mm, ID600mm, ID800mm, or ID1000mm DAC dynamic

axial compression column systems.

In addition, this system is also have options, as pump for automatic sample

loading, automatic fraction collector, integrated platform (Industrial PC) and

other configurations.

And is suitable for all kinds of chromatography model including normal phase,

reverse-phase, ion exchange, etc.

It is suitable for hundreds of grams and kilograms grade product separations.

|

|

3-1. GL3000-3L system

(recommended column: DAC300) |

|

|

|

Code

|

Remarks

|

Number

|

|

|

GL3000-3L-01 |

GL3000-3L/min Preparative high pressure pump for mobile phase streams |

2 |

|

|

GL3000-3L-02 |

GL3000-3Lmin Preparative high pressure pump for Sample loading or mobile phase streams |

1 |

|

|

GL3000-3L-03 |

UV-3292 UV/VIS detector

|

1 |

|

|

GL3000-3L-04 |

Preparative flow cell |

1 |

|

|

GL3000-3L-05 |

Preparative DAC column, ID300mm

|

1 |

|

|

GL3000-3L-06 |

Dynamic mixer(DT optional)

|

1 |

|

|

GL3000-3L-07 |

Fraction collector(optional, Valve/XY)

|

1 |

|

|

GL3000-3L-08 |

Online Filter(optional, GL100)

|

1 |

|

|

GL3000-3L-09 |

Equipment Framework(optional)

|

1 |

|

|

GL3000-3L-010 |

Embedded Industrial PC |

1 |

|

|

GL3000-3L-011 |

GL3000 chromatography workstation software |

1 |

|

|

GL3000-3L-012 |

Dedicated Tool kit |

1 |

|

|

GL3000-3L-013 |

Installation Startup Kit

|

1 |

|

|

GL3000-3L-014 |

Others |

1 |

|

|

3-2. GL3000-5L system

(recommended column: DAC450) |

|

|

|

Code

|

Remarks

|

Number

|

|

|

GL3000-5L-01 |

GL3000-5L/min Preparative high pressure pump for mobile phase streams |

2 |

|

|

GL3000-5L-02 |

GL3000-5L/min Preparative high pressure pump for Sample loading or mobile phase

streams |

1 |

|

|

GL3000-5L-03 |

UV-3292 UV/VIS detector

|

1 |

|

|

GL3000-5L-04 |

Preparative flow cell |

1 |

|

|

GL3000-5L-05 |

Preparative DAC column, ID450mm

|

1 |

|

|

GL3000-5L-06 |

Dynamic mixer(DT optional)

|

1 |

|

|

GL3000-5L-07 |

Fraction collector(optional, Valve/XY)

|

1 |

|

|

GL3000-5L-08 |

Online Filter(optional, GL100)

|

1 |

|

|

GL3000-5L-09 |

Equipment Framework(optional)

|

1 |

|

|

GL3000-5L-010 |

Embedded Industrial PCembedded Industrial PC |

1 |

|

|

GL3000-5L-011 |

GL3000 chromatography workstation software |

1 |

|

|

GL3000-L-012 |

Dedicated Tool kit |

1 |

|

|

GL3000-L-013 |

Installation Startup Kit

|

1 |

|

|

GL3000-5L-014 |

Others |

1 |

|

|

3-3. GL3000-10L system

(recommended column: DAC600) |

|

|

|

Code

|

Remarks

|

Number

|

|

|

GL3000-10L-01 |

GL3000-10L/min Preparative high pressure pump for mobile phase streams |

2 |

|

|

GL3000-10L-02 |

GL3000-10Lmin Preparative high pressure pump for Sample loading or mobile phase streams |

1 |

|

|

GL3000-10L-03 |

UV-3292 UV/VIS detector

|

1 |

|

|

GL3000-10L-04 |

Preparative flow cell |

1 |

|

|

GL3000-10L-05 |

Preparative DAC column, ID600mm

|

1 |

|

|

GL3000-10L-06 |

Dynamic mixer(DT optional)

|

1 |

|

|

GL3000-10L-07 |

Fraction collector(optional, Valve/XY)

|

1 |

|

|

GL3000-10L-08 |

Online Filter(optional, GL100)

|

1 |

|

|

GL3000-10L-09 |

Equipment Framework(optional)

|

1 |

|

|

GL3000-10L-010 |

Embedded Industrial PC |

1 |

|

|

GL3000-10L-011 |

GL3000 chromatography workstation software |

1 |

|

|

GL3000-10L-012 |

Dedicated Tool kit |

1 |

|

|

GL3000-10L-013 |

Installation Startup Kit

|

1 |

|

|

GL3000-10L-014 |

Others |

1 |

|

|

3-4. GL3000-20L system

(recommended column: DAC800) |

|

|

|

Code

|

Remarks

|

Number

|

|

|

GL3000-20L-01 |

GL3000-20L/min Preparative high pressure pump for mobile phase streams |

2 |

|

|

GL3000-20L-02 |

GL3000-20L/min Preparative high pressure pump for Sample loading or mobile phase

streams |

1 |

|

|

GL3000-20L-03 |

UV-3292 UV/VIS detector

|

1 |

|

|

GL3000-20L-04 |

Preparative flow cell |

1 |

|

|

GL3000-20L-05 |

Preparative DAC column, ID800mm

|

1 |

|

|

GL3000-20L-06 |

Dynamic mixer(DT optional)

|

1 |

|

|

GL3000-20L-07 |

Fraction collector(optional, Valve/XY)

|

1 |

|

|

GL3000-20L-08 |

Online Filter(optional, GL100)

|

1 |

|

|

GL3000-20L-09 |

Equipment Framework(optional)

|

1 |

|

|

GL3000-20L-010 |

embedded Industrial PCembedded Industrial PC |

1 |

|

|

GL3000-20L-011 |

GL3000 chromatography workstation software |

1 |

|

|

GL3000-20L-012 |

Dedicated Tool kit |

1 |

|

|

GL3000-20L-013 |

Installation Startup Kit

|

1 |

|

|

GL3000-20L-014 |

Others |

1 |

Modules introductions:

|

|

GL3000- Preparative high pressure pump Features:

(3L/min, 5L/min, 10L/min, 20L/min, 30L/min) |

|

|

|

1. Using the latest 32-bit RISC central ultra- high speed computing and 32 bit

DSP stepping drive control processors for core control. |

|

|

2. It is based on all digital frequency-based systems, advanced motor drive system and

friendly user display interface, making operation and control of the device more

convenient. |

|

|

3. Dual screw dual piston control, with the pump can be configured to isocratic, gradient

mode. |

|

|

4. High-precision screw drive model with high flow rate precision, good system

reproducibility and very low flow pulse features. |

|

|

5. Advanced pump head and check valve design ideas, a unique blend of the world's most

advanced experiences, allowing our users to guarantee the flow rate accuracy and

reproducibility specifications in various conditions. |

|

|

6. When working on the preparative high-pressure gradient mode, the

PC/Master module can control more than

one pumps of the same type, and can monitor gradient curve gradient method

through the PC/Master for verifications. |

|

|

7. A variety of communication modes, standard RS232, RS485, Ethernet interface, are selectable

for the preparative high-pressure pump control, which has greater advantages for

high purity sample preparation of

requirements. |

Technical specifications:

|

|

Stream infusion type |

Dual piston elution. |

|

|

Pump head material |

316L Stainless Steel/Other options |

|

|

Maximum operating pressure |

3L/min pump head: 1500psi(105 Kgf/cm2, Bar)

5L/min

pump head: 1500psi(105 kgf/cm2, Bar)

10L/min pump head: 1500psi(105 Kgf/cm2, Bar)

20L/min pump head: 1500psi(105 Kgf/cm2, Bar)

30L/min pump head: 1500psi(105 Kgf/cm2, Bar) |

|

|

Flow rate range |

3L/min pump head: 0-3Lmin

5L/min pump head: 0-5Lmin

10L/min pump head: 0-10Lmin

20L/min pump head: 0-20Lmin

30L/min pump head: 0-30Lmin |

|

|

Flow rate accuracy |

±1%, @1-99% flow rate range & MeOH: H2O (80%: 20)

|

|

|

Flow repeatability

|

RSD ≤1%

|

|

|

Display

|

192 × 64 pixels LCD screen |

|

|

System Protection |

Slow start and stop, auto-stop maximum pressure setting, data auto-stored

|

|

|

System Connection |

1/2 or 3/8 tubing connections |

|

|

Control |

Multiple communication modes, standard RS232, RS485, Ethernet interface for

high-pressure infusion pump control |

|

|

Power supply |

220V ± 10%, 50Hz, 1200W |

|

|

Dimensions |

650mm × 460mm × 300mm (Length × Width × Height) |

|

|

Transmission type |

Precision dual-actuators precision ball screw drive that is produced by the

HIWIN (Taiwan) with high precision, small pulses, good performance. Our pressure

can be displayed in bar that may sense to our very small pressure fluctuations

within 2bar. |

|

|

UV3292 SpectroDetector Features: |

|

|

|

1. Adopt all digital output design. After its signal is through 24 bit A/D, the

single-chip microcomputer finishes the process of data conversion and zero

setting, and the processed result will get the RS 232 interface. |

|

|

2. The gratting, directly fixed on the motor shaft of stepping motor, through

the procedure of single-chip microcomputer to take sine conversion, can control

the motor to choose the wavelength.Replace the traditional sine bar

organization, and further improve the reliability and stability of the system;

wavelength can be corrected once the system is started.

|

|

|

3. Programming control to wavelength. |

|

|

4. Flow-stopped automatic spectral scanning |

|

|

5. Flow cell has the "Z" style design and is processed by thermostatically

processing so that the noise and drift of equipment can be improved to the large

extent.

|

|

|

6. Light path is designed of double light beam so as to further minimize

drifting impact from the surrounding change.

|

|

|

7. Optical path can be adjusted through replacing flow cell and changing

corresponding system parameters, so it can be transferred from analytical style

to semi preparative and even to big preparative style easily. |

|

|

8. The simulative analog output port is equipped.

|

|

|

9. It can be controlled through RS-232 interface by chromatographic work

station. |

Technical specifications:

|

|

Wavelength range |

190~740nm |

|

|

Edge filter |

370nm

|

|

|

Light source |

Deuterium lamp, halogen tungsten lamp (optional) |

|

|

Band width |

8nm |

|

|

Wavelength precision |

±1nm |

|

|

Noise |

2*10-5AU (254nm@1ml/min @methanol)

|

|

|

Drift |

15*10-5AU/h 254nm@1ml/min @methanol)

|

|

|

Minimum testing concentration |

5*10-9g/ml (254nm@1ml/min@methanol@Naphthalene standard) |

|

|

Testing range |

0~2.5AU |

|

|

Display LCD |

2*16 English

|

|

|

GLP information |

working time of light source, times of light kindled

|

|

|

Dimension |

4600mm*330mm*180mm |

|

|

Dynamic Axial Compression Column Features:

(DAC Column) |

|

|

|

The DAC Summary:

It is the only one technology that is universally

recognizedto be able to maintain good separation effect under various column

chromatography scales, and it is also the best column packing technology in the

preparative chromatographic field,

The advanced DAC(Dynamic axial compression column) have its own functions, as

self-packing, column pressure maintain, and self-release-packing.

The DAC packed column bed fully meets the continuity, uniformity, stability, and

tightness requirements.

The mechanism of DAC column is through the up and down movement of the piston to

pack, maintain column pressure and release packing.

The piston surrounding is equipped with a specially designed seal rings that

allow the piston to freely slide up and down, while maintaining high sealing

pressure . Piston motion and pressure is maintained by the uniform and stable

hydraulic pressure.

The separation effects of DAC columns with various diameters approach or even

equivalent to the analytical column.

|

|

|

Performance & Features: |

|

|

|

1 |

Adopt advanced structure design, flexible and convenient operation, small volume

and good appearance. |

|

2 |

The packing material filling process is easy to learn, the packing time is

short, with low supported compressed air requirement, that just 6kg air pressure

is sufficient for up to 90 kg packing pressure within the column. The column

performance is nearly close to that of analytical column.

|

|

3 |

DAC tech can pressurize the chromatographic column bed constantly, and

effectively avoid the collapse of column head and loose column bed. |

|

4 |

Pressure endurance, Adhesiveness: the inner surface finish of ≥ ▽ 12, namely,

the surface roughness ≤0.25μm; concentricity between column head and cylinder

reaches 0.2um, column head sealing is made of imported oblique seals spring

seals, that make the column with high pressure endurance to 6000psi without

leakage and 50 times of refilling without wear. |

|

5 |

The distribution uniformity and reproducibility: column head, column bottom are

equipped with multi-point distribution technology components(our patent), that

will enable product solution and mobile phase to uniformly flush through the

column cylinder, with good peak symmetry. 6.Long service time. Once

chromatographic column is polluted, to discharg packing and then re-packing is

very easy and convenient. Pepeatly re-packing is also possible, which largely

prolongs the service life of chromatographic column.

|

|

6 |

Long service time. Once chromatographic column is polluted, to discharg packing

and then re-packing is very easy and convenient. Pepeatly re-packing is also

possible, which largely prolongs the service life of chromatographic column. |

|

7 |

The same packing system supports the filling of various specifications of columns whose inner diameter are less than

or equal to those of DAC dynamic axial compression columns.

|

|

8 |

The packed chromatographic column can be separated from packing system and be

used independently. Moreover, the stability of column bed and original column

performance can also be kept, and it is convenient to move to use. |

|

9 |

Adopt overpressure protection to guarantee the users' safety completely.

10.Sales price is only one third of or even lower than the similar imported

products. |

|

10 |

Sales price is only one third of or even lower than the similar imported

products |

|

|

|

Fraction collector Features:

(Valve 1In-7Out / XY24,48,96 wells) |

|

|

|

1. Automatic fraction collector has an all-digital design, whose signal is

processed by PLC and then the results will reach the RS232/485 interface. |

|

|

2. The equipment has programming control, combining with chromatograph can

finish the collection easily. |

|

|

3. The change of every peak is monitored with controlled collections by

chromatographic work station.

|

|

|

4. Both Valve-Switching and X-Y Movement types are available. 4. One collection

position is open all the time for and the others can be switched freely. |

|

|

5. Buttons on the front panel are can also be easily manual operated for peak

collections.

|

Technical specifications:

|

|

Channels(Valve type, GL-LF08-Valve) |

1 input

to 7 output channels

|

|

|

Number of Fractions

(X-Y type, GL-LF08-XY):

|

96, 48, 24 wells |

|

|

Collection Tube Volumes(X-Y type, GL-LF08-XY) |

50mL/96wells, 100mL/48wells, large volumes/24wells

|

|

|

Temperature control |

Room temperature, or optional for 2-8 degrees(C) |

|

|

Fraction Modes |

Manual or programmed fraction collection by peak slope, level, and time bands. |

|

|

Control |

PLC programmable control protocol. |

|

|

GL3000 Preparative Chromatography Workstation software Features: |

|

|

|

Chromatographic work station, matched with chromatograph, is the computer system

that can process chromatograph signal to be data.

The software focuses on intelligent process for spectrogram data, tries to

minimize the process knowledge of spectrogram data which should be mastered by

users, and transfers the knowledge to be clear and easy for users to understand,

so users will not see those baffling parameters in the chromatographic data

processor, (such as “Peak starting slope”, “parameter changing time”, “baseline

drift”, etc.)

It has overall professional functions, and when some special processing effect

is needed, there are still some simple and convenient adjustment methods.

Meanwhile, this software pursues succinct and compact interface layout, and

offers some functions like federated calculation, print by batch, result

summarizing, coherent operation, automatic save, and spectrogram management to

enhance daily analytical efficiency.

The above aspects mentioned make this software rich in function and convenient

in operation.

Another

distinguished characteristic of this software is that the close combination with

Microsoft office, like how to create analytical report in WORD, quantitative

result (or collection of several times’ quantitative results) which can be

delivered to EXCEL through clipping board, and

analytical records which can be saved in ACCESS database directly, etc.

When preparative chromatograph is put to use in

production, manual short line and notes can be generated on peak at any time.

|

|

|

|

4.Common spare and service parts

|

|

High pressure column seal ring |

|

Column filter |

|

|

|

|

|

|

|

|

|

|

|

Part No.

|

Description

|

Quantity |

|

Part No. |

Description |

Quantity |

|

|

GLO-ZM-001 |

25.4mm |

1 |

|

GL-ZG-001 |

25.4mm |

1 |

|

|

GLO-ZM-002 |

41.4mm |

1 |

|

GL-ZG-002 |

41.4mm |

1 |

|

|

GLO-ZM-003

|

50mm |

1 |

|

GL-ZG-003 |

77mm |

1 |

|

|

GLO-ZM-004

|

77mm

|

1 |

|

GL-ZG-004 |

100mm |

1 |

|

|

GLO-ZM-005

|

80mm

|

1 |

|

GL-ZG-005 |

150mm |

1 |

|

|

GLO-ZM-006

|

100mm |

1 |

|

GL-ZG-006 |

200mm |

1 |

|

|

GLO-ZM-007

|

150mm

|

1 |

|

GL-ZG-007 |

450mm |

1 |

|

|

GLO-ZM-008

|

200mm |

1 |

|

GL-ZG-008 |

600mm |

1 |

|

|

GLO-ZM-009

|

400mm |

1 |

|

GL-ZG-009 |

800mm |

1 |

|

|

GLO-ZM-010

|

600mm

|

1 |

|

GL-ZG-010 |

1000mm |

1 |

|

|

GLO-ZM-011

|

800mm |

1 |

|

|

|

|

|

|

GLO-ZM-012 |

1200mm |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High pressure pump seal ring |

|

Pump check valve |

|

|

|

|

|

|

|

|

|

|

|

Part No.

|

Description

|

Quantity |

|

Part No. |

Description |

Quantity |

|

|

GL-GM-001 |

50mL |

1 |

|

GL-BD-001 |

50mL |

1 |

|

|

GL-GM-002 |

100mL |

1 |

|

GL-BD-002 |

100mL |

1 |

|

|

GL-GM-003 |

250mL |

1 |

|

GL-BD-003 |

250mL |

1 |

|

|

GL-GM-004 |

500mL |

1 |

|

GL-BD-004 |

500mL |

1 |

|

|

GL-GM-005 |

1L |

1 |

|

GL-BD-005 |

1L |

1 |

|

|

GL-GM-006 |

2L |

1 |

|

GL-BD-006 |

2L |

1 |

|

|

GL-GM-007 |

3L |

1 |

|

GL-BD-007 |

3L |

1 |

|

|

GL-GM-008 |

5L |

1 |

|

GL-BD-008 |

5L |

1 |

|

|

GL-GM-009 |

10L |

1 |

|

GL-BD-009 |

10L |

1 |

|

|

GL-GM-010 |

20L |

1 |

|

GL-BD-010 |

20L |

1 |

|

|

GL-GM-011 |

30L |

1 |

|

GL-BD-011 |

30L |

1 |

|

|

Low pressure pump seal ring |

|

|

|

|

|

|

|

|

|

|

|

|

|

Part No.

|

Description

|

Quantity |

|

Part No. |

Description |

Quantity |

|

|

GL-DM-001 |

50mL |

1 |

|

GL-DZ-001 |

50mL |

1 |

|

|

GL-DM-002 |

100mL |

1 |

|

GL-DZ-002 |

100mL |

1 |

|

|

GL-DM-003 |

250mL |

1 |

|

GL-DZ-003 |

250mL |

1 |

|

|

GL-DM-004 |

500mL |

1 |

|

GL-DZ-004 |

500mL |

1 |

|

|

GL-DM-005 |

1L |

1 |

|

GL-DZ-005 |

1L |

1 |

|

|

GL-DM-006 |

2L |

1 |

|

GL-DZ-006 |

2L |

1 |

|

|

GL-DM-007 |

3L |

1 |

|

GL-DZ-007 |

3L |

1 |

|

|

GL-DM-008 |

5L |

1 |

|

GL-DZ-008 |

5L |

1 |

|

|

GL-DM-009 |

10L |

1 |

|

GL-DZ-009 |

10L |

1 |

|

|

GL-DM-010 |

20L |

1 |

|

GL-DZ-010 |

20L |

1 |

|

|

GL-DM-011 |

30L |

1 |

|

GL-DZ-011 |

30L |

1 |

|

|

|

|

|

|

|

|

|

|

|

Manual injection valve |

|

Deuterium lamp |

|

|

|

|

|

|

|

|

|

|

|

Part No.

|

Description

|

Quantity |

|

Part No. |

Description |

Quantity |

|

|

GLP-JY-001 |

Parts for 3725i-038/Rheodyne manual injection valve |

|

GLP-DA-001 |

Deuterium lamp |

|

|

|

|

|

|

|

|

|

|

|

|

Quantitative sample loop |

|

Flow cell |

|

|

|

|

|

|

|

|

|

|

|

Part No.

|

Description

|

Quantity |

|

Part No. |

|

Quantity |

|

|

GP-DL-001 |

2mL |

1 |

|

GL-LT-001 |

Semi preparative

flow cell |

1 |

|

|

GP-DL-002 |

5mL |

1 |

|

GL-ZL-002 |

Preparative flow cell |

1 |

|

|

GP-DL-003 |

10mL |

1 |

|

|

|

|

|

|

GP-DL-004 |

20mL |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plunger rod |

|

Stainless steel tubing |

|

|

|

|

|

|

|

|

|

|

|

Part No.

|

Description

|

Quantity |

|

Part No. |

Description

|

Quantity |

|

|

GL-ZS-001 |

50mL |

1 |

|

GL-BX-001 |

316L 1/16” |

1 |

|

|

GL-ZS-002 |

100mL |

1 |

|

GL-BX-002 |

316L 1/8" |

1 |

|

|

GL-ZS-003 |

250mL |

1 |

|

GL-BX-003 |

316L 1/4" |

1 |

|

|

GL-ZS-004 |

500mL |

1 |

|

|

|

|

|

|

GL-ZS-005 |

1L |

1 |

|

Peek connector |

|

|

GL-ZS-006 |

2L |

1 |

|

|

|

|

|

|

GL-ZS-007 |

3L |

1 |

|

Part No. |

Description

|

Quantity |

|

|

GL-ZS-008 |

5L |

1 |

|

GL-JT-001 |

316L 1/16” |

1 |

|

|

GL-ZS-009 |

10L |

1 |

|

GL-JT-002 |

316L 1/8" |

1 |

|

|

GL-ZS-010 |

20L |

1 |

|

GL-JT-003 |

316L 1/4" |

1 |

|

|

GL-ZS-011 |

30L |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Packing Materials |

|

Reagents |

|

|

|

|

|

|

|

|

Part No.

|

Description

|

Quantity |

|

Part No. |

Description

|

Quantity |

|

|

YMC, Calesil, Fuji, and global major brands, ... |

|

by orders. |

|

Three. Sample separation service

|

|

We set up a customer product separation center, with a Chromatography team with

a number of application engineers, experienced in the API, Chinese medicine

monomer, peptide drugs, etc. and dedicated for our customer services for more

than 12 years.

We provide fast separation and purification solutions and products purification

and service for you.

We offer a variety cooperation modes to reduce the risk and cost of your product

research and development process. |

|

|

|

|

|

|

|

Four. Customer Examples

|

|

After more than 12 years of unremitting efforts, we have more than 400 large

high-precision and high-performance systems installed in China (with total

market share > 1/3), and USA. With more than major 150 customers, including the

well-known pharmaceutical companies and research institutions, we have acquired

customer recognition and praise in the chromatography industry field. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|