|

Product

Description Product

Description

The P-16+ stylus profiler is a surface metrology analysis solution

used in a wide range of applications and industries

, from R&D departments and universities to production and process monitoring.

This surface analysis solution's precise force control provides excellent

vertical resolution, precision, and reliability measurements.

This surface analysis solution delivers automated step height analysis,

surface contour, waviness and roughness measurements with detailed 2D

or 3D analysis of topography for a variety of surfaces and materials.

P-16+探針式表面量測儀,

是一個應用及工業範圍很廣的表面量測

分析解決方案, 從研究開發部門及大學研究所, 到產品製造, 製程監控等.

此方案的精準的力量的控制, 提供了優越的垂直解析度

, 精準度及可靠度的量測. 此方案, 為各種不同的表面及材料

, 帶來具有詳細的二維及三維的量測分析, 的自動化的梯度高度分析

, 表面輪廓, 紋波, 粗糙度等的量測.

Application

- Semiconductor

CMP monitoring and bump metrology

- Material

Science

Thin film thickness, roughness and stress analysis

- Data

Storage

Thin film head structure definition and disk edge

roll-off

- Optoelectronics

Microlens and diffuser shape

- MEMS

Etch rates and trench depth analysis

應用:

半導體, 材料科學,

資料儲存體, 光電, 微機電元件等.

RELATED INFORMATION (下載)

P-16+

PRODUCT OVERVIEW

(產品概要介紹)

THE P-16+ and P-16 OF+ (open frame) surface profilers

provide complete, detailed two- and three-dimensional analysis of surface topography for a variety of surfaces

including semiconductor wafers, C4 bumps, thin-film heads and disks, MEMS, opto-electronics, thin film/chemical

coatings, biomedical devices and flat panel displays.

P-16+ 以及 P-16+ OF(開架式)表面量測儀, 提供完整,

詳細的各種不同C4焊接點, 薄型薄膜頭及碟片微機電元件, 光電, 薄型薄膜/化學鍍膜, 生醫器件 及平板顯示器等.

This tool uses a diamond stylus for advanced profiling

applications on a Windows® XP operating system. With its

intuitive menus, the P-16+ system provides measurement

data such as step height, surface roughness, microwaviness,

and overall substrate form, with excellent vertical

resolution, precision, and reliability.

這個工具用一個鑽石的探針及 Window 作業系統, 於進階剖面量測應用,以其直覺的選單, P-16+ 以優越的垂直解析度,

精準度及可靠度, 提供如梯度高度, 表面粗糙度,微小波紋度,以及整體的基材的形狀等的量測數據.

The system’s three

different measurement head configurations offer flexibility

for a wide range of vertical topography, with top and side

view optics for simple sample positioning.

此系統的三個不同的量測頭的組態,

對於寬廣範圍的垂直測繪提供了彈性,

且以上視及側視的光學方式作簡單的樣品定位.

Two special

hardware configurations allow the open frame version to accommodate either large substrates up to 19 inches in

length or full access to a 300 mm diameter wafer.

二個不同的硬體組態,

使得開架式的版本可以適用長度至10英吋的大基材,

或是達 300 mm 直徑的晶圓的全部但圍的讀取.

|

PRODUCT DESCRIPTION

Classic Contact Profiling(傳統接觸式表面量測)

Offers long-scan capability up to 200 mm and vertical range up to

1 mm for large topography variations. While scanning, the stylus

remains in constant contact with the sample surface by means of

a user-specified force. 3D scans can also be generated with lateral

line-to-line spacing of 1 μm or larger.

提供達

200 mm的長-掃描的能力,以及垂直凡圍達到 1mm,

用於大的形狀差異的量測. 在掃描的時後,

探針以使用者指定的力量,

與樣品的表面維持恆定的接觸. 三維的掃描,

也能夠以側邊 ,1微米或大些的掃描線與掃描線間格來產生.

Step Height Repeatability(梯度高度的可重復性)

A step height repeatability of 6Å or 0.1% (1σ) allows the precise

determination of step heights, surface roughness and waviness,and curvature. This performance is ensured with ultra-low-noise

electronics, and a low-mass, low-inertia capacitive sensor with

sub-Angstrom resolution.

6Å or 0.1% (1σ)

的梯度高度的可重復性, 可得到精準的梯度高度,

表面粗糙度, 波紋度及灣曲程度的量測.

這個性能, 以超低雜訊的電子元組件, 低質量,

低慣性, 具有"次-埃"

等級解析度的電容式感測器, 來加以確保.

Variable Measurement Head Configurations

(可變換的量測頭的組態)

Available in three different measurement head

configurations, the Microhead 5 SR offers classical stylus control with

programmable force and standard vertical ranges.

可取得

3種不同的量測頭的組態, Microhead 5 SR

提供的是傳統的可程控力量探針控制及標準的垂直方向範圍.

The Microhead

5 LF low-force measurement head delivers precision measurements on soft surfaces by using

sub-milligram forces

as low as 0.05 mg, and a lower vertical range.

Microhead 5

LF 低-力量 量測頭,

提供的是在軟性表面的精準量測,

所用的為可低到0.05 mg 的 sub-milligram

級的力量, 以及低(短)的垂直方向範圍.

In addition, the

Microhead 5 XR provides an extended vertical range of 1 mm

and forces as low as 0.5 mg.

此外,

Microhead 5 XR 量測頭, 則提供的是可括充到 1mm

的垂直方向範圍, 以及可低到0.5 mg 探針力量.

Top and Side View Optics(上視及側視光學部份)

All three Microhead options also offer top and side view optics,

allowing the operator to automatically switch between a topdown

view for fast stylus positioning and navigating over the sample, and an angled view for easy monitoring of the stylus as

it scans over target features.

所有的

Microhead 量測頭, 都提供上視及側視光學部份,

讓使用者可以在用於快速探針位置定位於及在樣品上移動的上視方式,

與用於容易監視掃描目標特徵中的探針的

角度側視方式, 之間自動切換.

Hardware Stage Configuration(硬體平台的組態)

The P-16 OF+ version has two additional sample stage configurations. The XLS stage provides full access to a 9.5 x 9.5

inch area and can accommodate square or rectangular samples

having a length up to 19 inches. The 300 mm stage configuration

allows full wafer access to 300 mm wafer.

P-16 OF+

版本, 有兩個增加樣品平台組態. XLS平台提供達9.5 x 9.5

英吋面積的完整存取, 以及可以用在長度達

19 英吋 的方型或長方型樣品. 其 300mm

的平台組態, 可允許達300mm 晶圓的完整存取. |

|

|

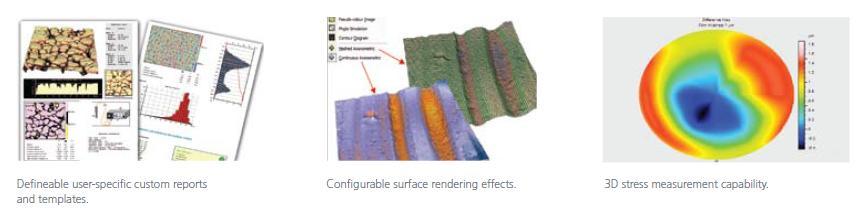

Apex Software

This software processes over 40 key surface parameters to analyze

depth, step height, roughness, waviness, slope, flatness, radius of

curvature, stress, bearing ratio, distance, volume and peak count

distribution (other parameters).

這個軟體可處理超過

40 個以上關鍵的表面參數,

以便用於分析深度, 梯度深度, 粗糙度,

波紋度, 斜率, 平整度, 灣曲半徑, 應力,

磨損比, 距離, 體積, 以及尖峰(凸起)數量的分佈(其他參數).

In addition, it isolates roughness

and waviness components from the raw data trace using a variety

of standard filters including Cubic Spline and Gaussian.

此外,

它(軟體)使用各種標準的過濾演算法,

包括三次方取線規函數, 高斯函數,

從原始數據的蹤跡裏, 將粗糙度與波紋度分離出來.

Since data is

saved as raw data, the user can always go back and add or exclude

parameters of interest. Apex has a simple and intuitive format that

allows for an easy creation of customized reports while also having

the support for multiple language offerings.

因為數據是以原始數據的型態儲存,

使用者一直都能夠回溯,

加入或排除感興趣的參數. Apex

有一個簡單直覺的格式,

允許可以容意地產生報表,

同時也提供多國語言的支援.

POWERFUL OPTIONS(強而有力的附加項目)

A variety of options are available to significantly enhance the

capabilities of the P-16+ and P-16 OF+ system beyond single-scan

2D measurements and trace analysis:

有各種附加項目可取得,

以明顯地加強 P-16+ 及 P-16 OF+

系統的能力, 使超出單-掃描 2

維量測及微小軌跡的分析.

Productivity Package(生產力補充包)

The productivity package includes Pattern Recognition combined

with sequence software for improved overall throughput and enduser/

fab productivity.

Pattern Recognition enhances automation of

data acquisition by automatically positioning the sample and taking

measurements with minimum operator intervention. The Sequence

software enhances throughput by automatically scanning up to

1000 programmed sites per recipe. 生產力補充包,

包括有與序列結合的圖案模式辨識軟體,

用於增進整體產能及終端使用者或製造廠的生產力.

圖案模式辨識,

經由自動樣品的定位及最少操作者介入的量測過程,

增強了數據擇取的自動化.

序列軟體,

經由自動掃描每個測定設計方法, 高達1000

個可程式設定的位置, 增強了產能.

|

3D Imaging(三維影像建構)

Enables three-dimensional imaging and viewing of surface

topography in photo-realistic, color-coded, and rotatable 3D

or top-down contour maps. Allows comprehensive analysis of

scanned features as they appear in 3D and in 2D by examining

cross-sections.

以

合理相片, 顏顏編碼,

以及可旋轉的三維或由上到下的輪廓地圖,

來觀看量測表面,

使能夠進行三維影像的建構.

2D or 3D Stress Analysis(二維或三維的應力分析)

Calculates the stress on substrates by comparing substrate

bow before and after processing. Measures and computes the

average, minimum, and maximum stress in MPa. 3D Stress is

available only with Apex software.

比較處理程序的前後的灣曲程度,

可計算出基材上的應力情況.量測並計算其應力的平均值,

最小值及最大值(單為MPA).三維的應力只在Apex軟體裏.

Combined Statistics(結合的統計)

A program that calculates statistics for multiple data sets.

一個計算多數資料集合的程式.

Offline Analysis Software(離線分析軟體)

Allows data to be analyzed on a remote computer. Also, recipes

and sequences can be created and edited.

允許數據可以在遠端電腦上分析.

各種測定設計方法及序列設定也可以在遠端電腦上被產生與編輯.

SECS/GEM II

Full SEMI E30 compliant SECS/GEM allows upload of data to

a host computer for archiving and host monitoring. Provides

bi-directional transfer of recipes and sequences for remote,

automatic instrument setup.

完全符合

SEMI E30 compliant SECS/GEM 規範,

允許上傳數據到主機電腦上,

作為建檔備存及備存控管.

在遠端控制的自動儀器設定時, 提供雙向的測定設計方法及序列設定的傳輸.

|

BENEFITS(優點)

• Extensive list of standard features including

Apex 2D, 20-site sequence and dual view optics

• Advanced multi-language Apex surface analysis

software for improved user-friendliness and

larger worldwide acceptance

• Optional productivity package for increased

automation and throughput

• Fast, accurate location of measurement features

with minimum operator intervention

• Unmatched repeatability and reproducibility

for reliable measurements

• Long-scan capability and vertical range for

flexibility in large topography variations

• Semi S2-0703, S8-0705 and S14-0704

compliance. RoHS compliance for computer

and all peripherals

可以列出很多的標準特點,

包括 Apex 2D, 20 位置的序列, 及雙視向光學.

先進的多國語言的Apex表面分析軟體,

增進使用者親合力及全世界的接受度.

選購的生產力補充包,

增加自動化及生產力.

以最少的使用者介入,

快速,準確的找到所要量測的特徵.

用於可靠的量測,

無與倫比的重複性與在現性.

長-掃描的能力及垂直方向的範圍,

用於得到大的型貌量測差異所需的彈性.

符合

Semi S2-0703, S8-0705 and S14-0704 規範.

符合 RoHS 的電腦及週邊的 規範

|

APPLICATIONS(應用)

Semiconductors(半導體)

CMP dishing, pattern-dependent erosion, surface topography

characterization, and oxide planarity for greater device

performance and yield loss reduction. Measures height,

co-planarity and roughness of bumps for flip chip technology.

Performs etch depth monitoring on open geometries with

automated analysis and simple process set-ups.

化學機械研磨,

圖案模式侵蝕, 表面特徵量測,

氧化物平整度等(量測),

用於得到更好的設備器件的性能及產率漏失的減少.

Data Storage(資料儲存體)

Thin film head wafers and sliders, hard disks, optical and

magnetic media. Wafer applications include plating thickness,

coil heights, and CMP planarity. Slider applications include

pole-tip recession analysis, air bearing cavities, and laser texture

bump characterization that includes bump height, width, and

depth analysis.

MEMS and Opto-Electronic(微機電)

MEMS and Opto-Electronics step heights, micro-lens height and

curvature, and DWDM etch depths.

微機電及光電元件結構的梯度高度,

微透鏡的高度及曲率, 以及DWDM

濾波長多工器的蝕刻深度等.

Other Applications(其他應用)

Hybrid circuits and ceramic substrates, paper and foil finishes,

polished and machined surfaces, coated or painted surfaces,

and precision-machined surfaces of any kind.

混合電路及陶磁基材,

紙張及錫箔的磨光, 拋光及機械加工的表面,

披覆或塗佈的表面,以及任何經過精密機械加工的表面.

|

KLA-TENCOR SERVICE/SUPPORT

Customer service is an integral part of KLA-Tencor’s portfolio that enables our customers to accelerate yield. Our vast

customer service organization collaborates with worldwide customers to achieve the required productivity and performance

at the lowest cost. K-T Services includes comprehensive contracts, time and materials, spares, asset management, customer

training, and yield consulting

客戶服務是

KLA-Tencor’s 使我們的客戶加速產能的整體的一部份.

我們龐大的客戶服務組織,

與世界各地的客戶協力合作,

使能夠以最低的成本,

達倒所需要的生產力的性能. KLA-TENCOR 的服務包括,

一般性企約, 時間及材料, 備料,資產管理,

客戶訓練, 及產率咨詢等.

|

KLA-Tencor Corporation

One Technology Drive

Milpitas, CA 95035

phone 408.875.3000

www.kla-tencor.com |

|

Product

Description

Product

Description