|

Ultrafiltration & Microfiltrations

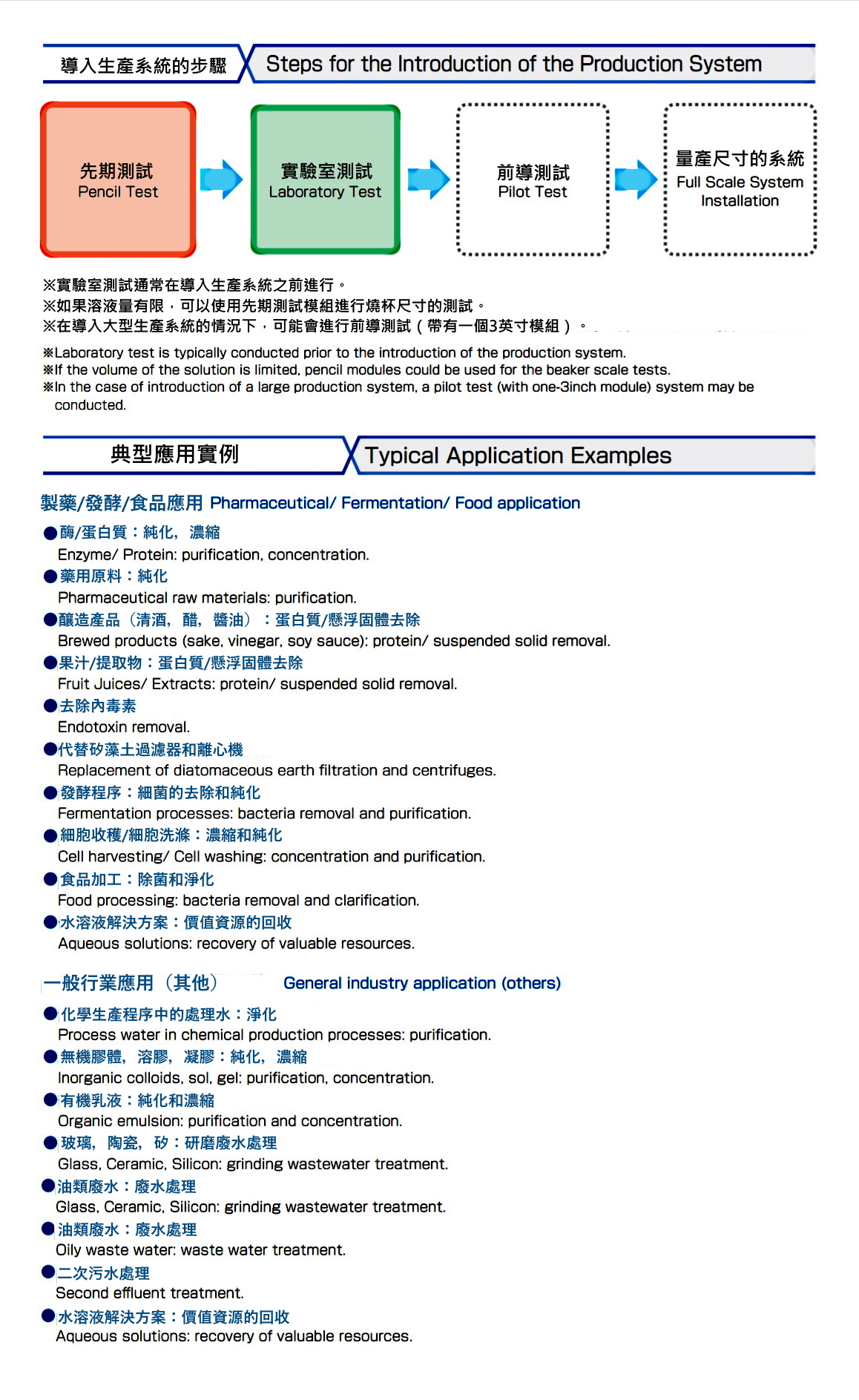

Pencil Test / Laboratory Test / Pilot Test / Full Scale

Knowledge base :

Membrane separation processes, Pore size and selectivity,

Ultrafiltration (UF),

Microfiltration

Ultrafiltration for a swimming pool |

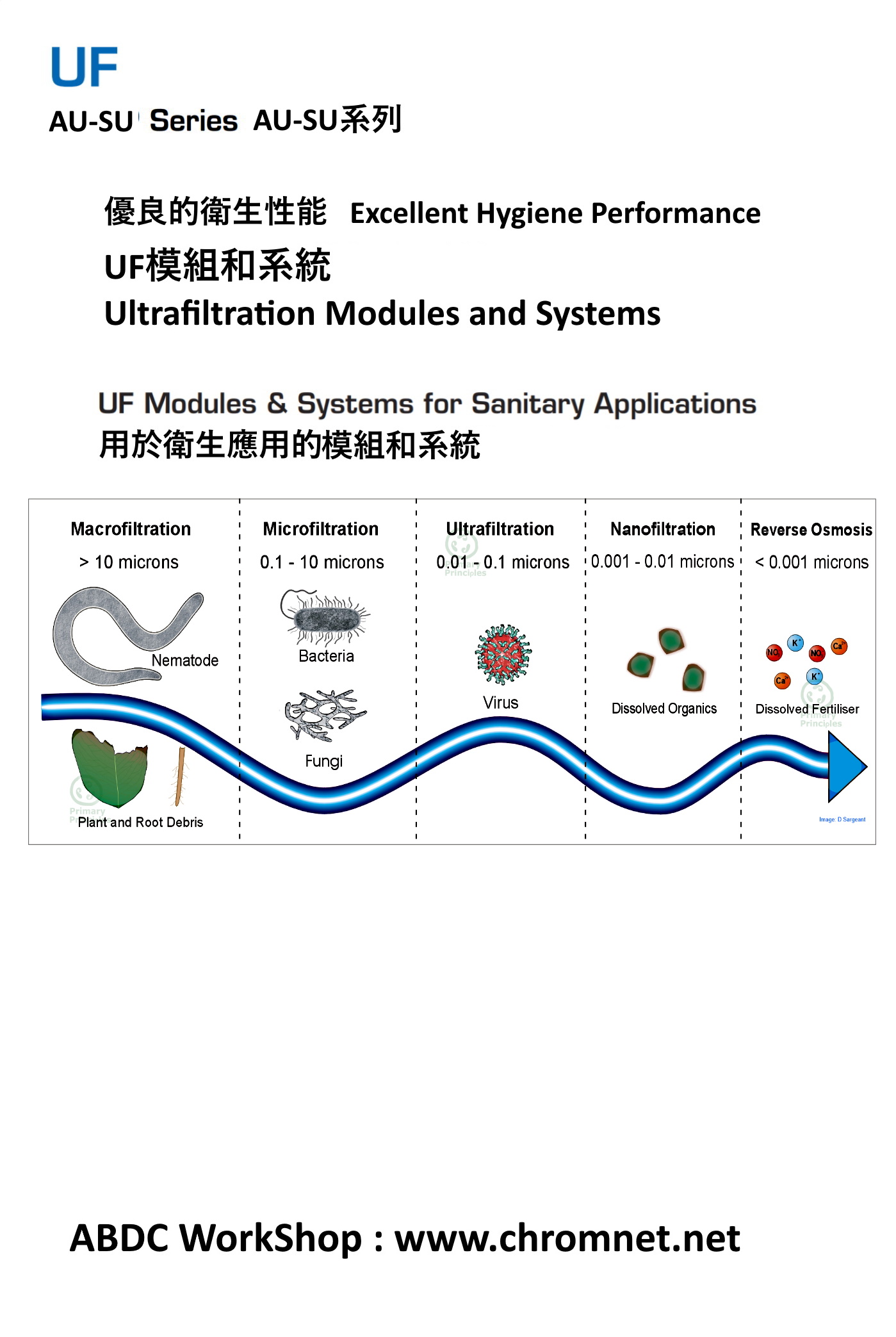

Membrane separation processes have a very important role in the separation industry. Nevertheless, they were not considered technically important until the mid-1970s. Membrane separation processes differ based on separation mechanisms and size of the separated particles. The widely used membrane processes include microfiltration, ultrafiltration, nanofiltration, reverse

osmosis, electrolysis, dialysis, electrodialysis, gas separation, vapor permeation, pervaporation, membrane distillation,

and membrane contactors. All processes except for pervaporation involve no phase change. All processes except (electro)dialysis are pressure driven. Microfiltration and ultrafiltration is widely used in food and beverage processing (beer microfiltration, apple juice ultrafiltration), biotechnological applications and pharmaceutical industry (antibiotic production,

protein purification), water purification and wastewater treatment, the microelectronics industry, and others. Nanofiltration and reverse osmosis membranes are mainly used for water purification purposes. Dense membranes are utilized for gas separations (removal of CO2 from natural gas, separating N2 from air, organic vapor removal from air or a nitrogen stream) and sometimes in membrane distillation. The later process helps in the separation of azeotropic compositions reducing the costs of distillation processes.

|

|

Pore size and selectivity

The pore sizes of technical membranes are specified differently depending on the manufacturer. One common distinction is by nominal pore size. It describes the maximum pore size distribution[4] and gives only vague information about the retention capacity of a membrane. The exclusion limit or "cut-off" of the membrane is usually specified in the form of NMWC (nominal molecular weight cut-off, or MWCO, molecular

weight cut off, with units in Dalton). It is defined as the minimum molecular weight of a globular molecule that is retained to 90% by the membrane. The cut-off, depending on the method, can by converted to so-called D90, which is then expressed in a metric unit. In practice the MWCO of the membrane should be at least 20% lower than the molecular weight of the molecule that is to be separated.

Using track etched mica membranes Beck and Schultz demonstrated that hindered diffusion of molecules in pores can be described by the Renkin equation.

|

Ranges of membrane based separations |

|

Filter membranes are divided into four classes according to pore size:

| Pore size |

Molecular mass |

Process |

Filtration |

Removal of |

| > 10 |

|

"Classic" filter |

|

|

| > 0.1 μm |

> 5000 kDa |

microfiltration |

< 2 bar |

larger bacteria, yeast, particles |

| 100-2 nm |

5-5000 kDa |

ultrafiltration |

1-10 bar |

bacteria, macromolecules, proteins, larger viruses |

| 2-1 nm |

0.1-5 kDa |

nanofiltration |

3-20 bar |

viruses, 2- valent ions[8] |

| < 1 nm |

< 100 Da |

reverse osmosis |

10-80 bar |

salts, small organic molecules |

|

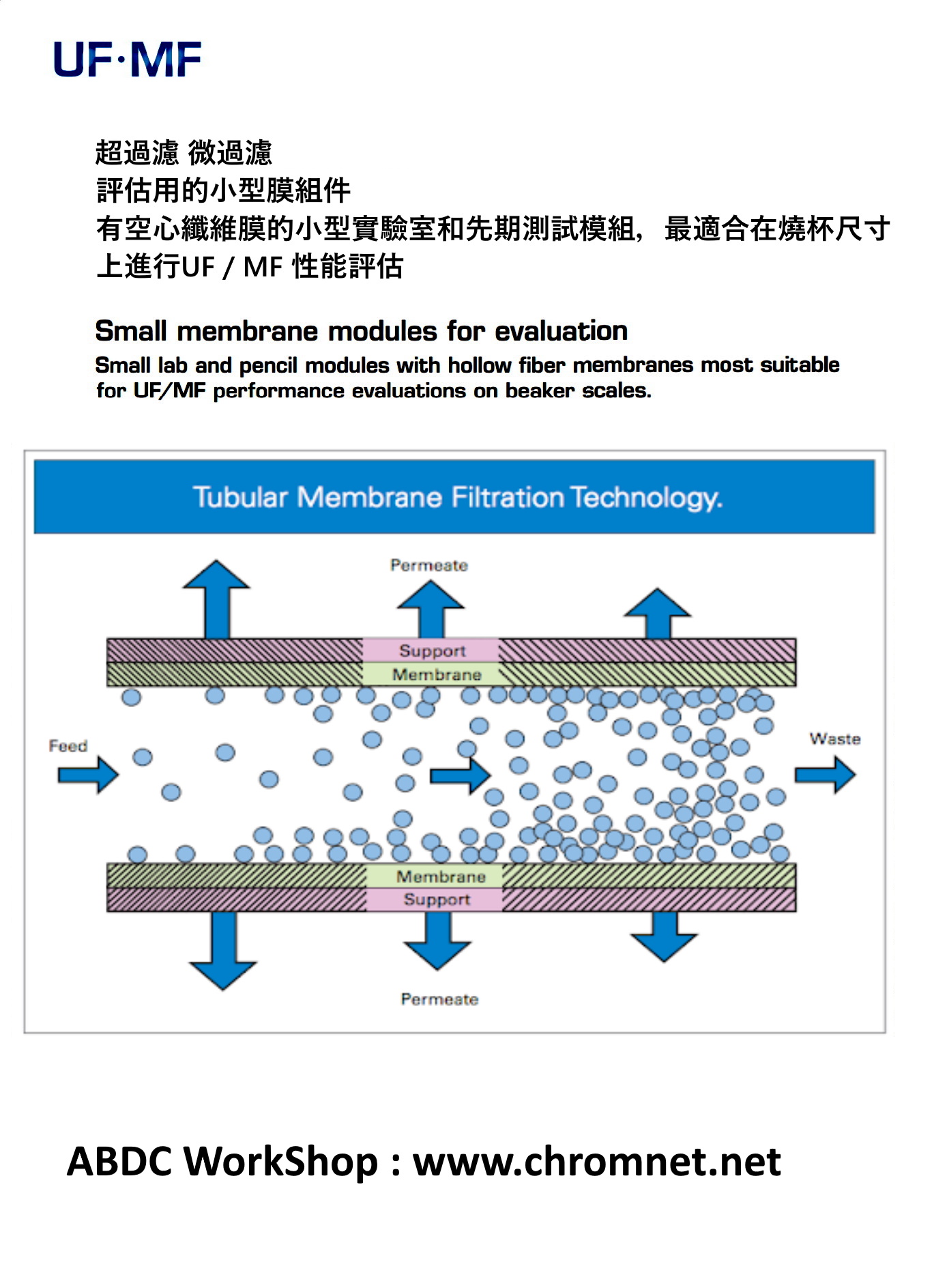

Diagram of cross-flow filtration

|

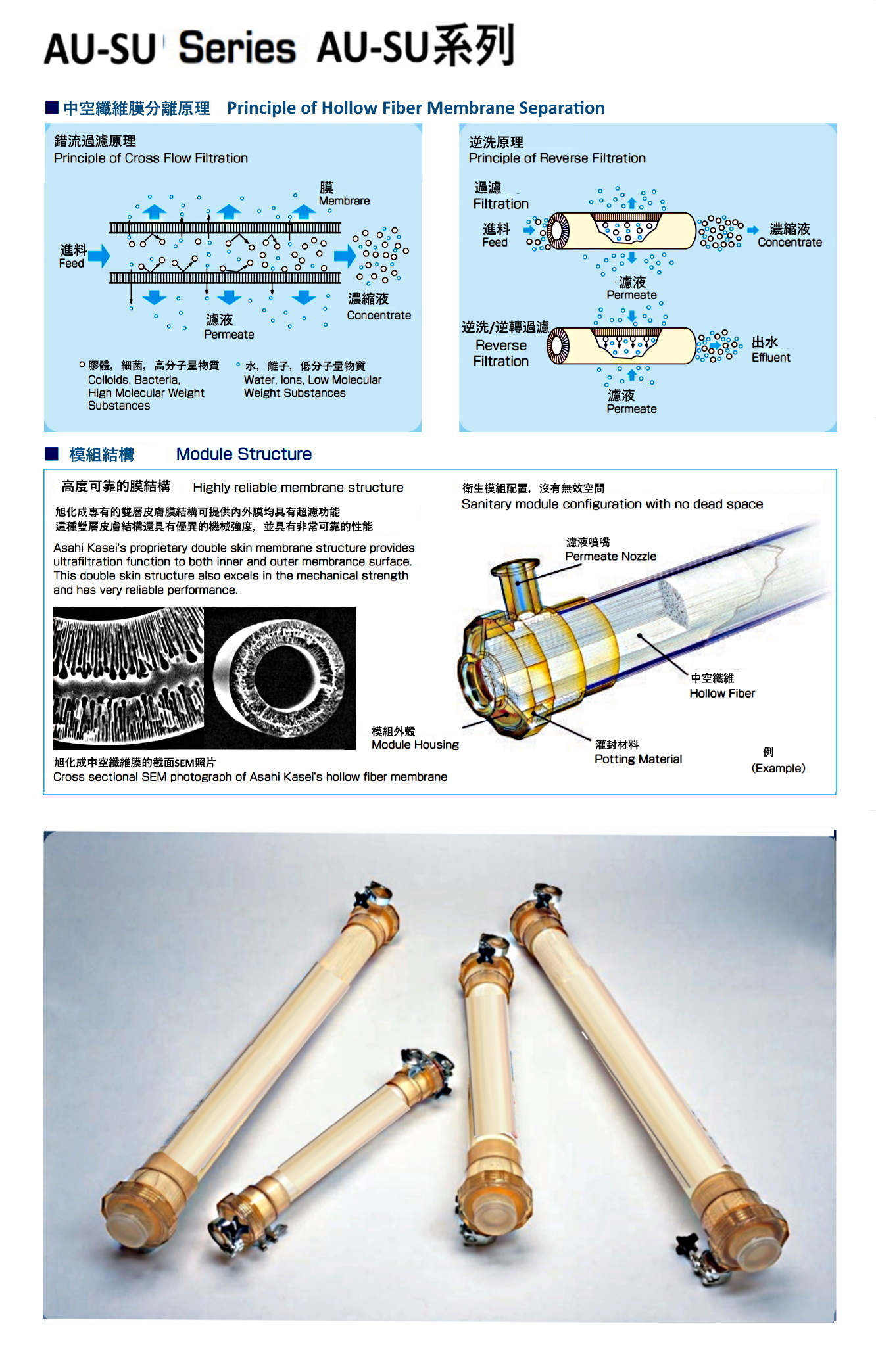

Cross-flow filtration

In chemical engineering, biochemical

engineering and protein

purification, crossflow

filtration (also known as tangential

flow filtration) is a type of filtration (a

particular unit operation). Crossflow filtration is

different from dead-end filtration in

which the feed is passed through a membrane or

bed, the solids being trapped in the filter and

the filtrate being

released at the other end. Cross-flow filtration gets its name because the majority of the feed flow travels tangentially across the

surface of the filter, rather than into the filter.

|

|

Ultrafiltration (UF) is a variety of membrane filtration in which forces like pressure or concentration gradients lead to a separation through a semipermeable

membrane. Suspended solids and solutes of high molecular weight are retained in the so-called retentate, while water and low molecular weight solutes pass through the membrane in the permeate (filtrate). This separation

process is used in industry and research for purifying and concentrating macromolecular (103 - 106 Da) solutions, especially protein solutions.

Ultrafiltration is not fundamentally different from microfiltration. Both of these separate based on size exclusion or particle capture. It is fundamentally different from membrane gas separation, which separate based on different amounts of absorption and different rates of diffusion.

Ultrafiltration membranes are defined by the molecular weight cut-off (MWCO) of the membrane used. Ultrafiltration is applied in cross-flow or dead-end mode.

Using track etched mica membranes Beck and Schultz demonstrated that hindered diffusion of molecules in pores can be described by the Renkin equation.

|

Hollow fibre module |

|

The process characteristics of a UF system are highly dependent on the type of membrane used and its application. Manufacturers' specifications of the membrane tend to limit the process to the following typical specifications:

|

Hollow Fibre |

Spiral-wound |

Ceramic Tubular |

Plate and Frame |

| pH |

2–13 |

2–11 |

3–7 |

|

| Feed Pressure (psi) |

9–15 |

<30–120 |

60–100 |

|

| Backwash Pressure (psi) |

9–15 |

20–40 |

10–30 |

|

| Temperature (°C) |

5–30 |

5–45 |

5–400 |

|

| Total Dissolved Solids (mg/L) |

<1000 |

<600 |

<500 |

|

| Total Suspended Solids (mg/L) |

<500 |

<450 |

<300 |

|

| Turbidity (NTU) |

<15 |

<1 |

<10 |

|

| Iron (mg/L) |

<5 |

<5 |

<5 |

|

| Oils and Greases (mg/L) |

<0.1 |

<0.1 |

<0.1 |

|

| Solvents, phenols (mg/L) |

<0.1 |

<0.1 |

<0.1 |

|

|

Process design variables

|

Fundamental design heuristics

A few important design heuristics and their assessment are discussed below:

- When treating raw contaminated fluids, hard sharp materials can wear and tear the porous cavities in the micro-filter, rendering it ineffective. Liquids must be subjected to pre-treatment before passage through the micro-filter.[20] This may be achieved by a variation of macro separation processes such as screening, or granular media filtration.

- When undertaking cleaning regimes the membrane must not dry out once it has been contacted by the process stream.

[21] Thorough water rinsing of the membrane modules, pipelines, pumps and other unit connections should be carried out until the end water appears clean.

Microfiltration modules are typically set to operate at pressures of 100 to 400 kPa.[22] Such pressures allow removal of materials such as sand, slits and clays, and also bacteria and protozoa.

When the membrane modules are being used for the first time, i.e. during plant start-up, conditions need to be well devised. Generally a slow-start is required when the feed is introduced into the modules, since even slight perturbations above the critical flux will result in irreversible fouling.[23]

Like any other membranes, microfiltration membranes are prone to fouling. (See Figure 4 below) It is therefore necessary that regular maintenance be carried out to prolong the life of the membrane module.

- Routine 'backwashing', is used to achieve this. Depending on the specific application of the membrane, backwashing is carried out in short durations (typically 3 to 180 s) and in moderately frequent intervals (5 min to several hours). Turbulent flow conditions with Reynolds numbers greater than 2100, ideally between 3000 - 5000 should be used.[24] This should not however be confused with 'backflushing', a more rigorous and thorough cleaning

technique, commonly practiced in cases of particulate and colloidal fouling.

- When major cleaning is needed to remove entrained particles, a CIP (Clean In Place) technique is used.

[25] Cleaning agents/detergents, such as sodium

hypochlorite, citric acid, caustic soda or even special enzymes are typically used for this purpose. The concentration of these chemicals is dependent on the type of the membrane (its sensitivity to strong chemicals), but also the type of matter (e.g. scaling due to the presence of calcium ions) to be removed.

Another method to increase the lifespan of the membrane may be feasible to design two microfiltration membranes in series. The first filter would be used for pre-treatment of the liquid passing through the membrane, where larger particles and deposits are captured on the cartridge. The second filter would act as an extra "check" for particles which are able to pass through the first membrane as well as provide screening for particles on the lower spectrum of the range.

|

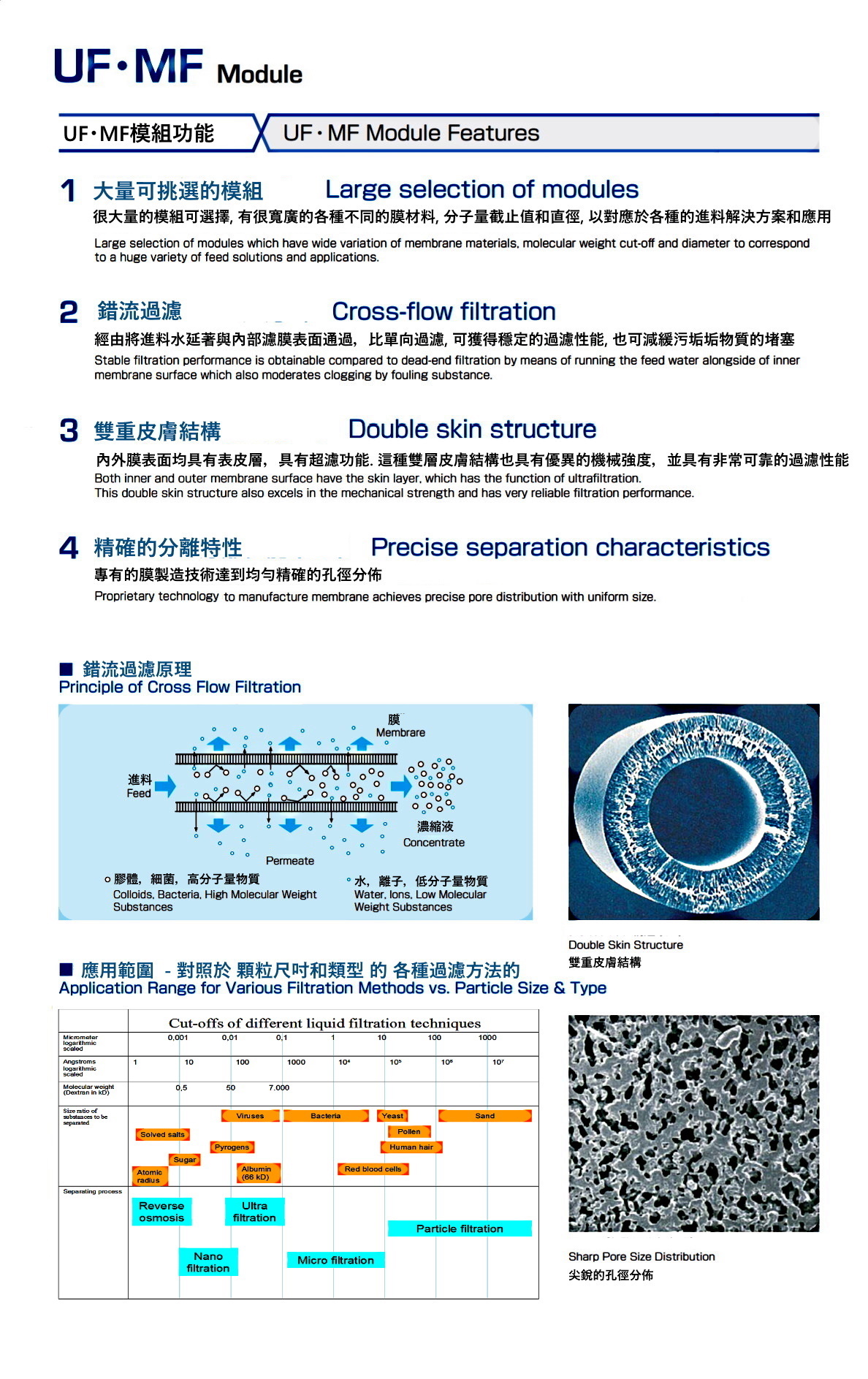

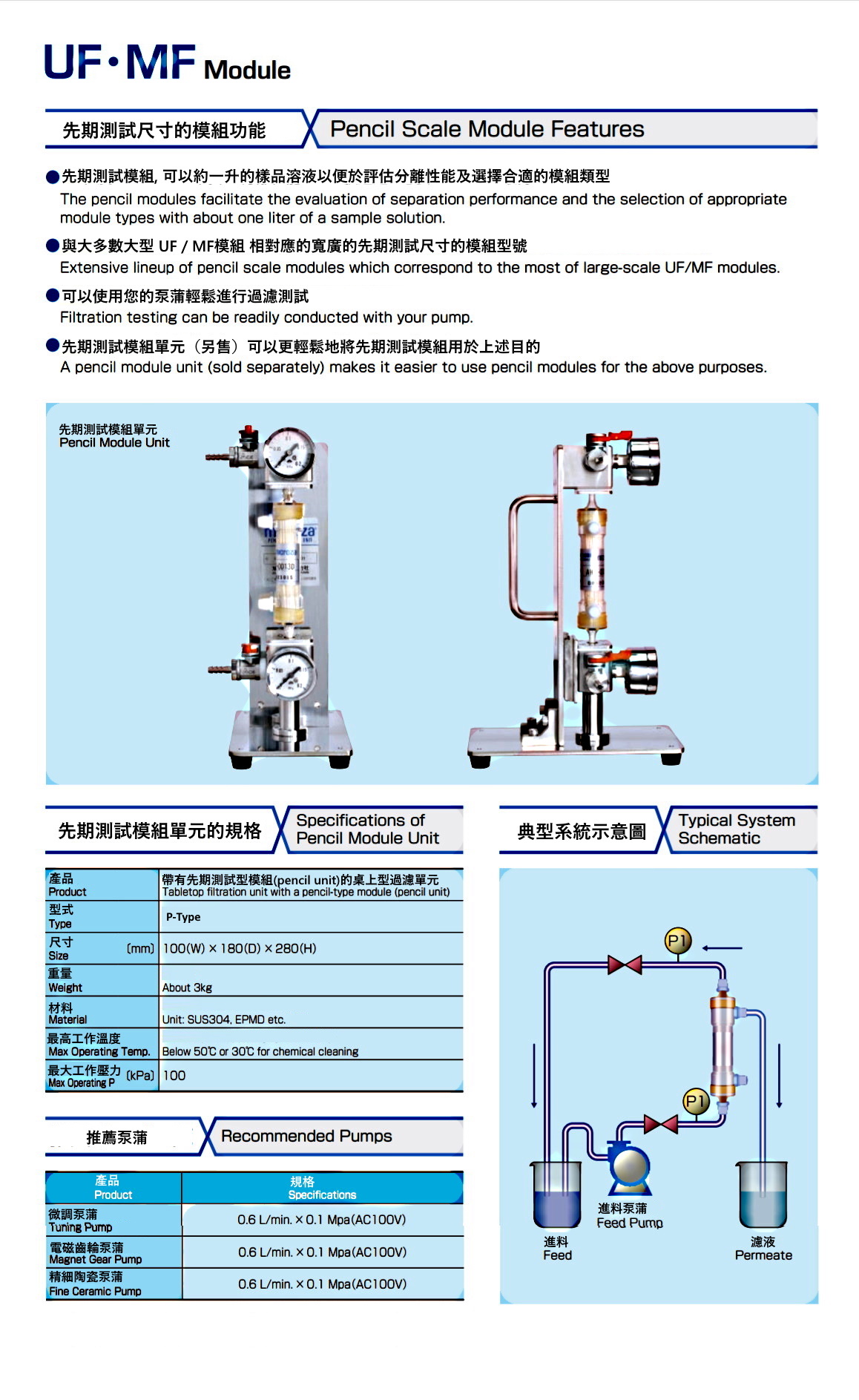

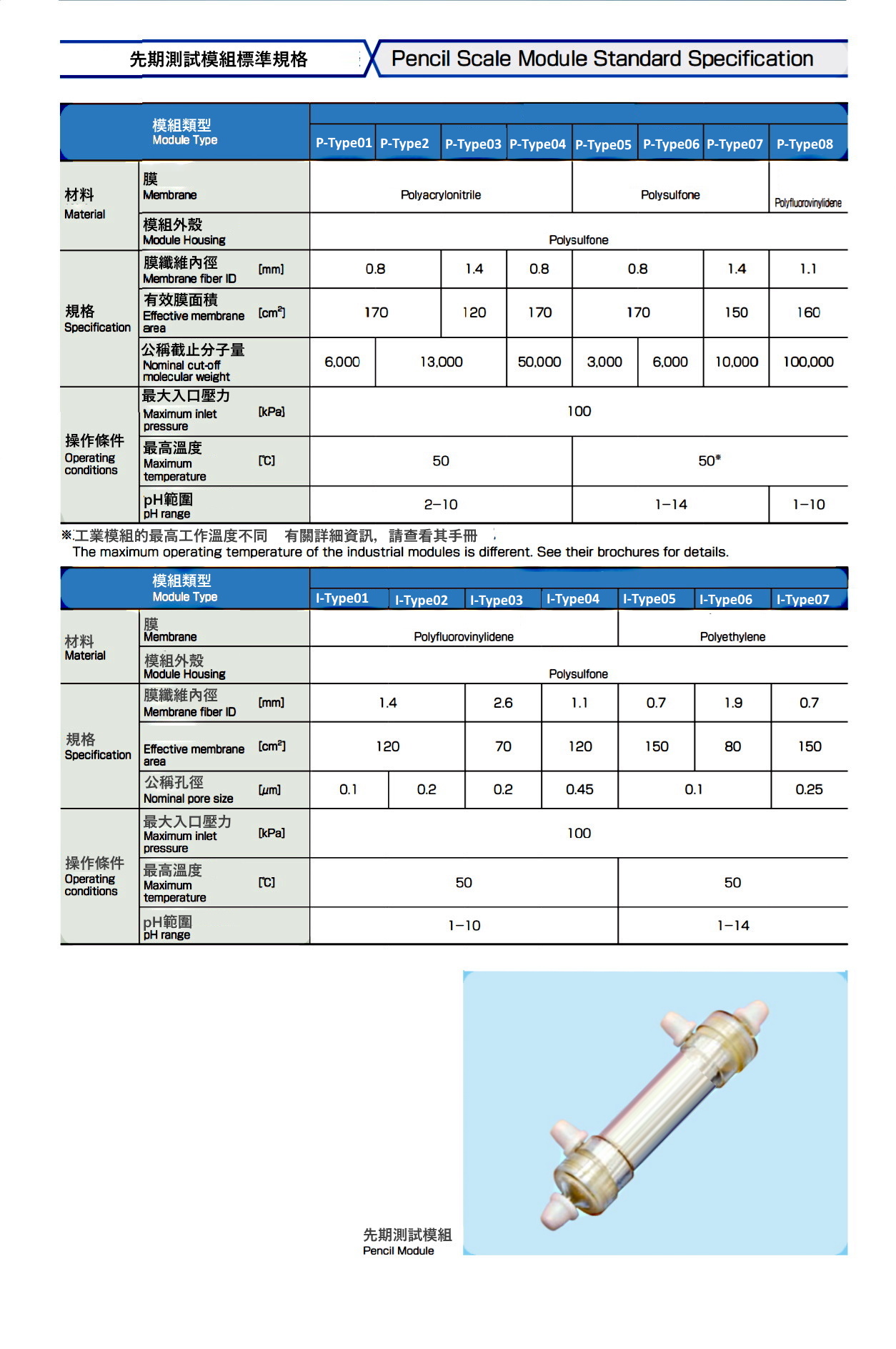

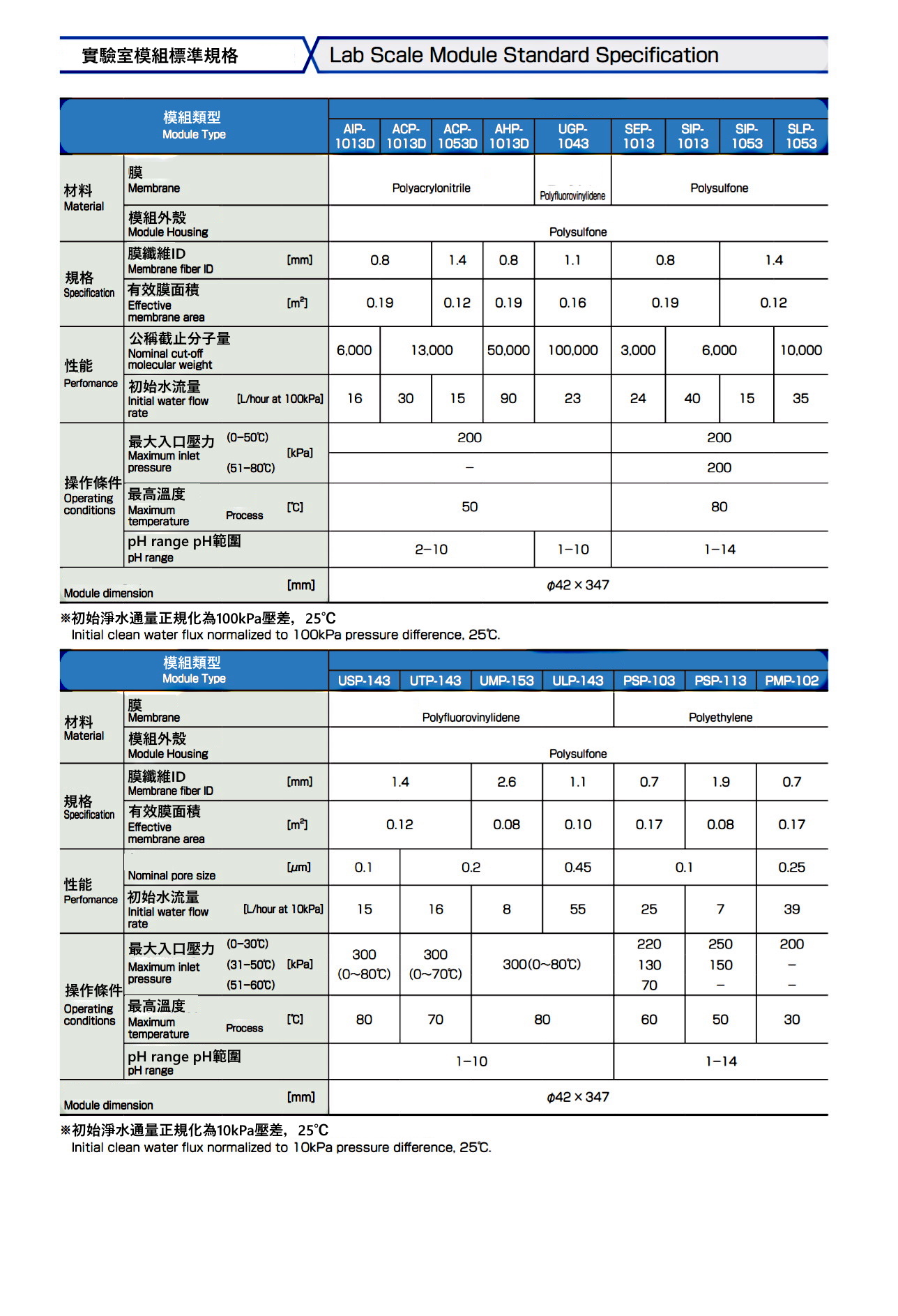

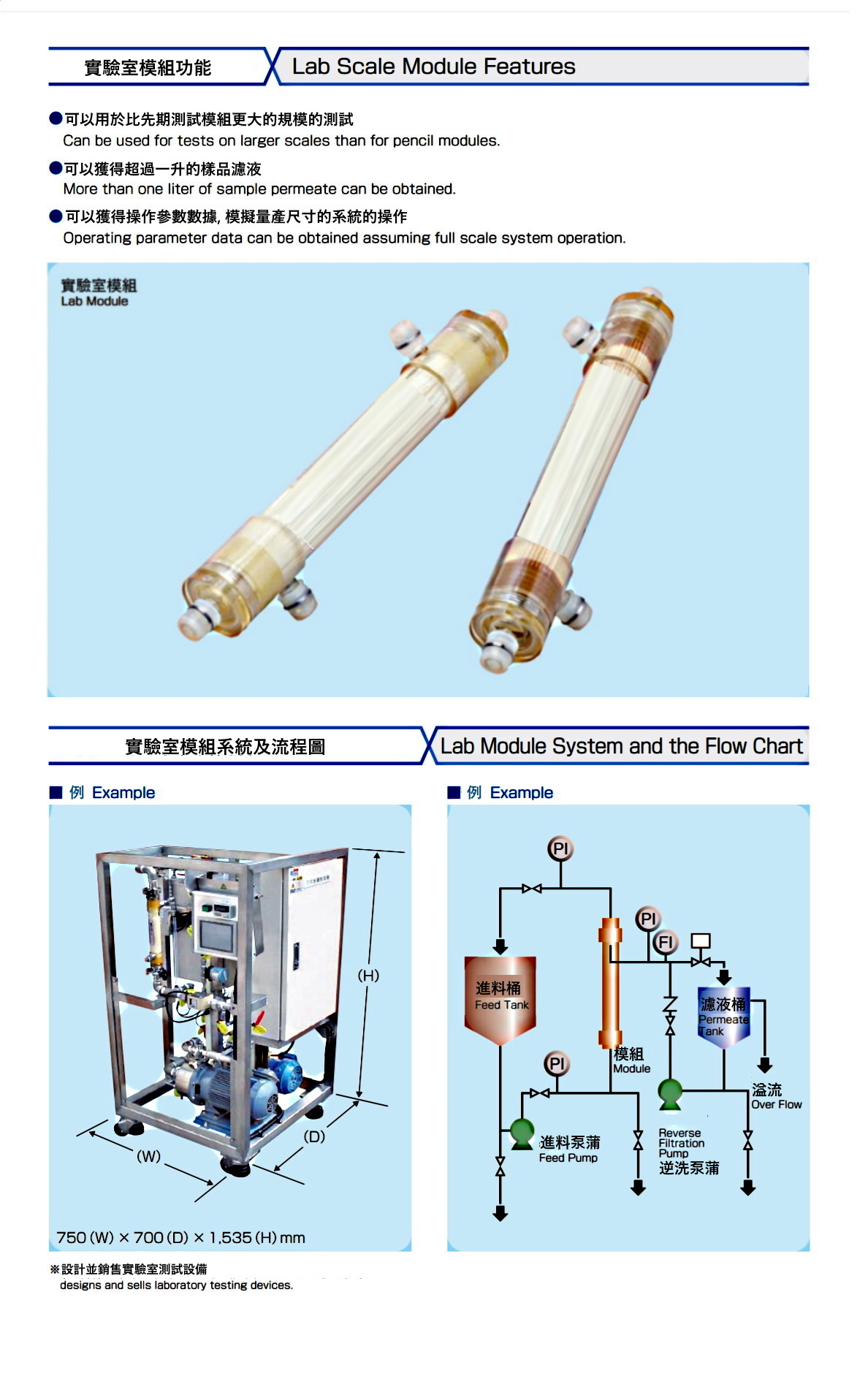

Leading with Quality, Performance and Cost

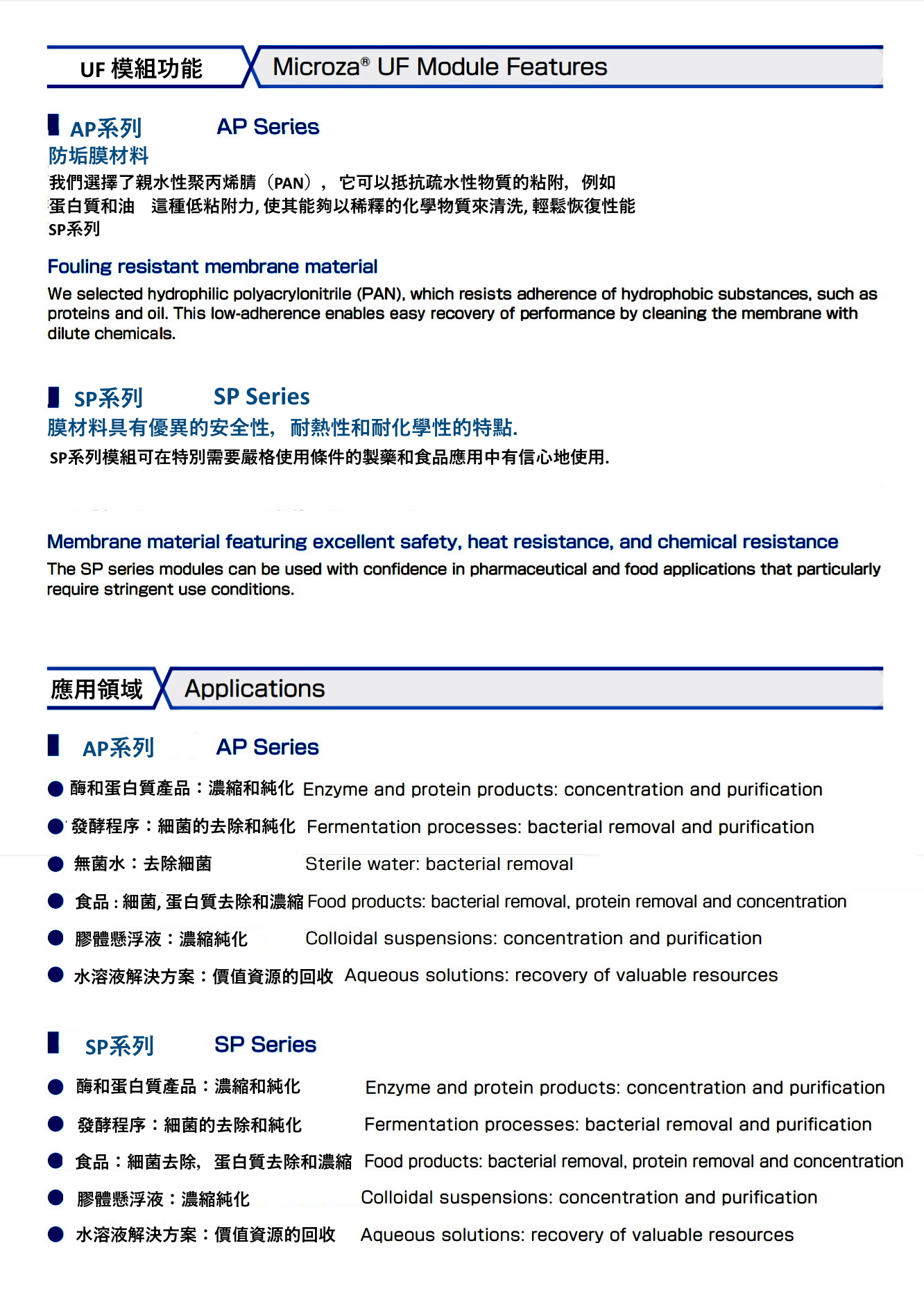

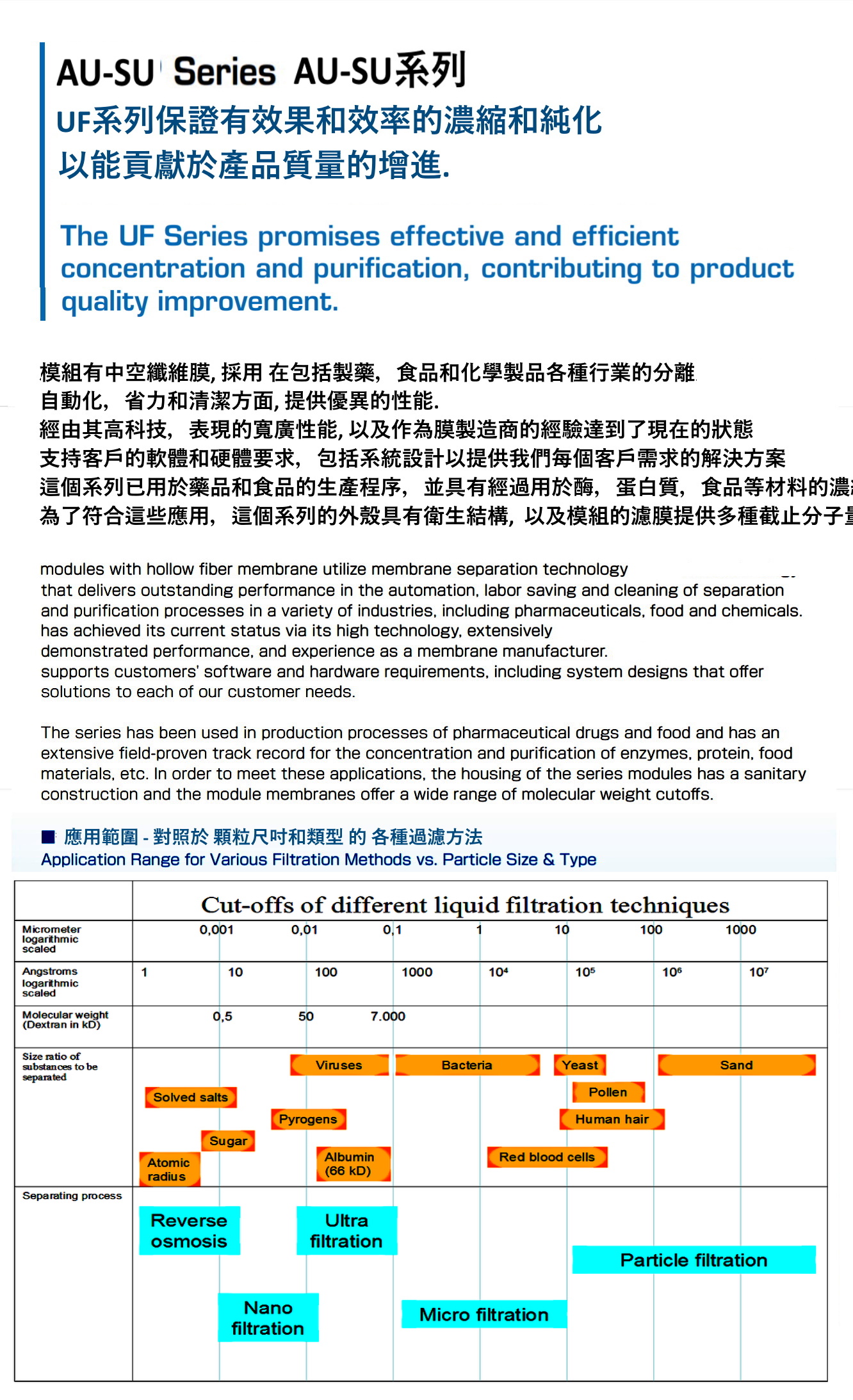

Microza is a filtration module containing unique hollow fiber membranes developed by Asahi Kasei for filtration systems. Several types of hollow fiber membranes are available, and in various organic polymers. Liquid filtration takes place through the pores, or gaps, in the hollow fiber wall structure. Microza membranes have sharp pore size distributions that provide superior and stable filtration performance.

Microza is a propriety brand if the the Asahi Kasei Group, a diversified group of companies led by Asahi Kasei Corp., with operations in the Material, Homes, and Health Care business sectors. With more than 35,000 employees around the world, the Asahi Kasei Group serves customers in more than 100 countries. Asahi Kasei is “Creating for Tomorrow” with all operations sharing a common mission of contributing to life and living for people around

the world. Founded in 1922 established the Asahi Fabric Co., Ltd. , Asahi Kasei Group has Growth as a diversified chemical manufacturer.

......

Highly Efficient, Precise Filtration, Durable ModuleDeployed in various liquid separation, filtration, and purification processes, is a filtration module containing unique hollow fiber membranes developed by Asahi Kasei for filtration systems. Several types of hollow fiber membranes are available, and in various organic polymers. Liquid filtration takes place through the pores, or gaps, in the hollow fiber wall structure. membranes have

sharp pore size distributions that provide superior and stable filtration performance. There are two categories of hollow fiber membranes; 1- microfiltration (MF) membranes and 2 - ultrafiltration (UF) membranes. These are available in a variety of product types and system configurations to meet variant filtration requirements. has an established track record for high performance in a wide variety of applications. These are not limited to the chemicals and precision electronics industries, but are also applicable and receiving very high ratings in municipal water, wastewater, food, pharmaceutical, energy, and environmental applications.

|

|