|

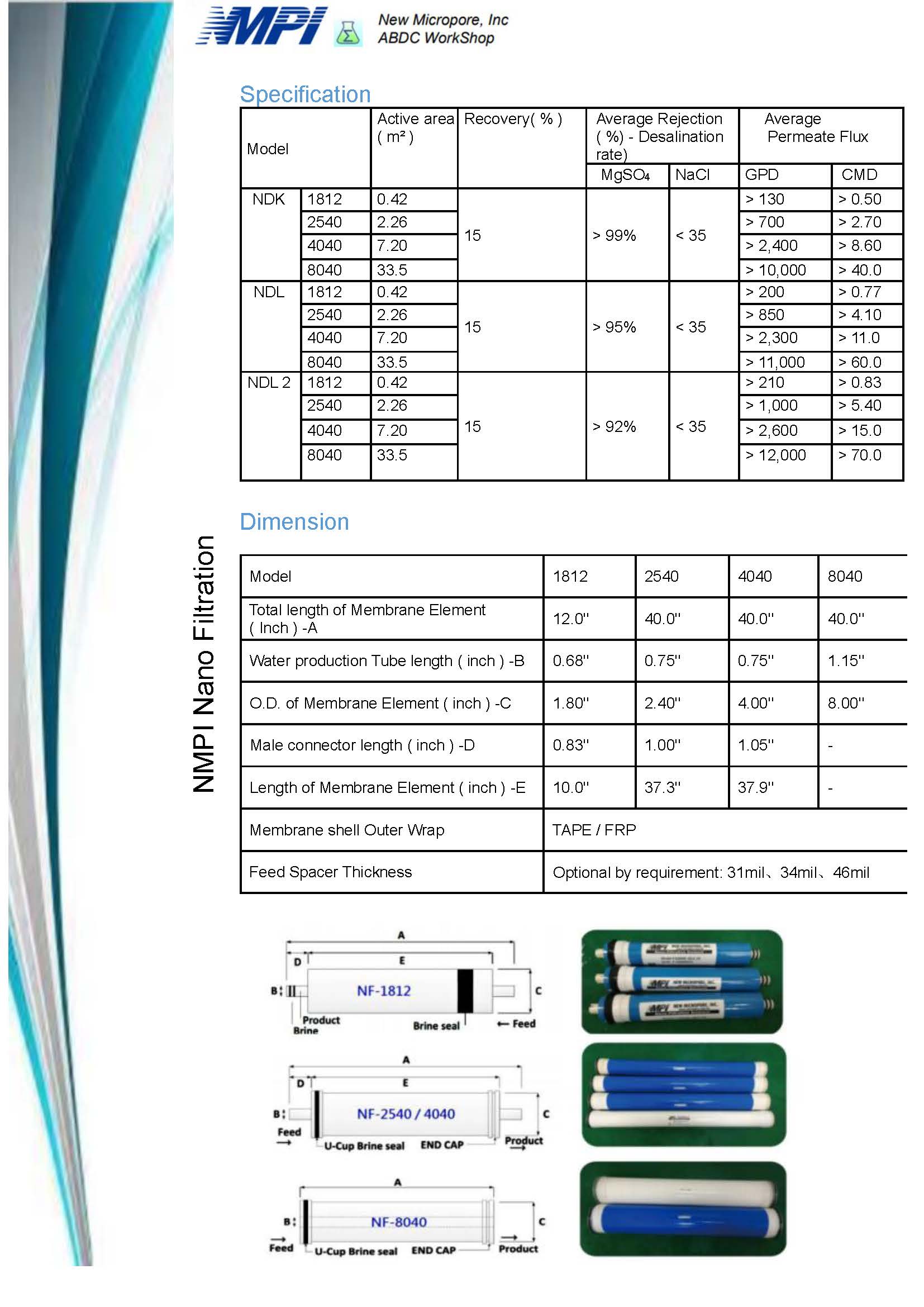

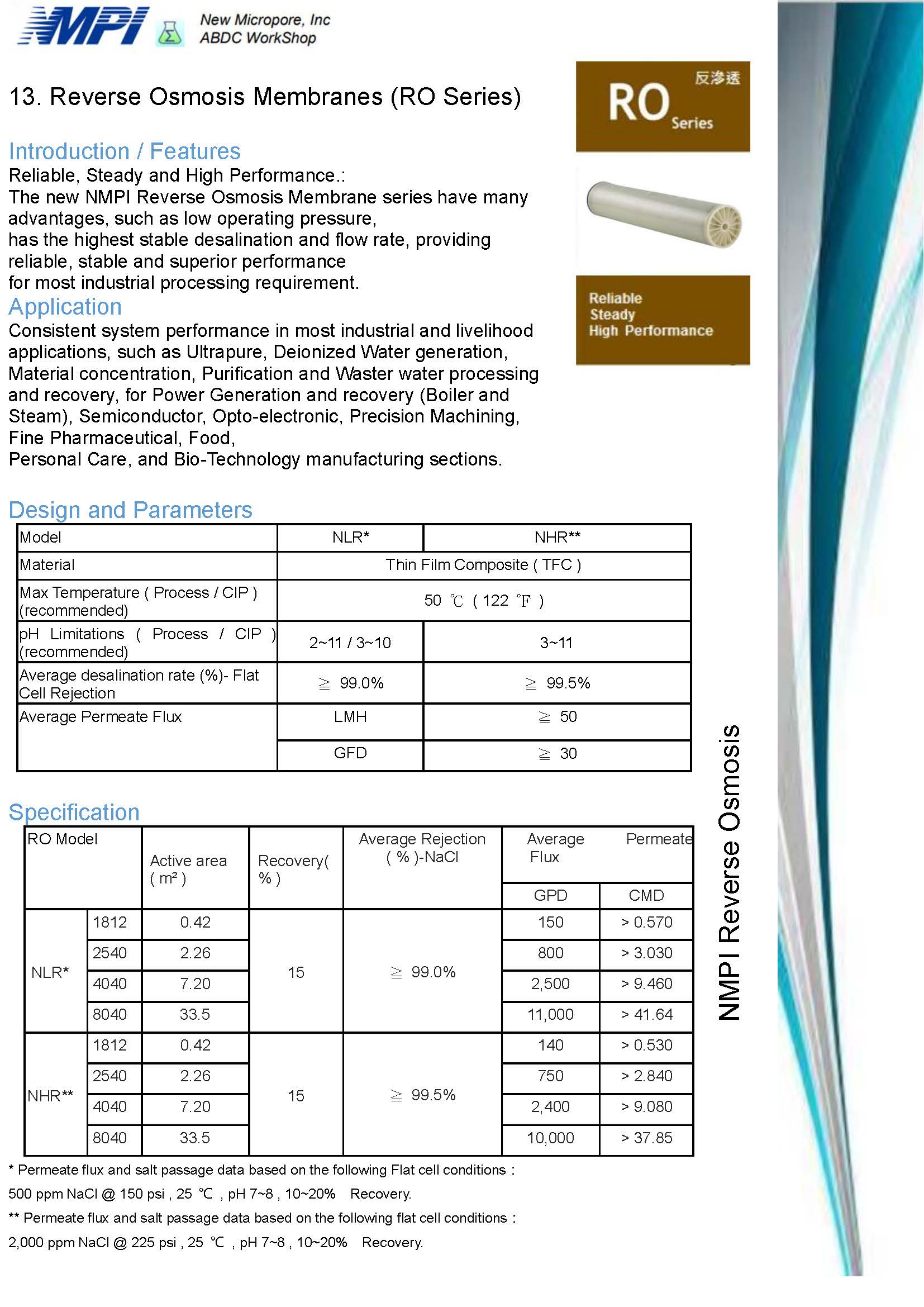

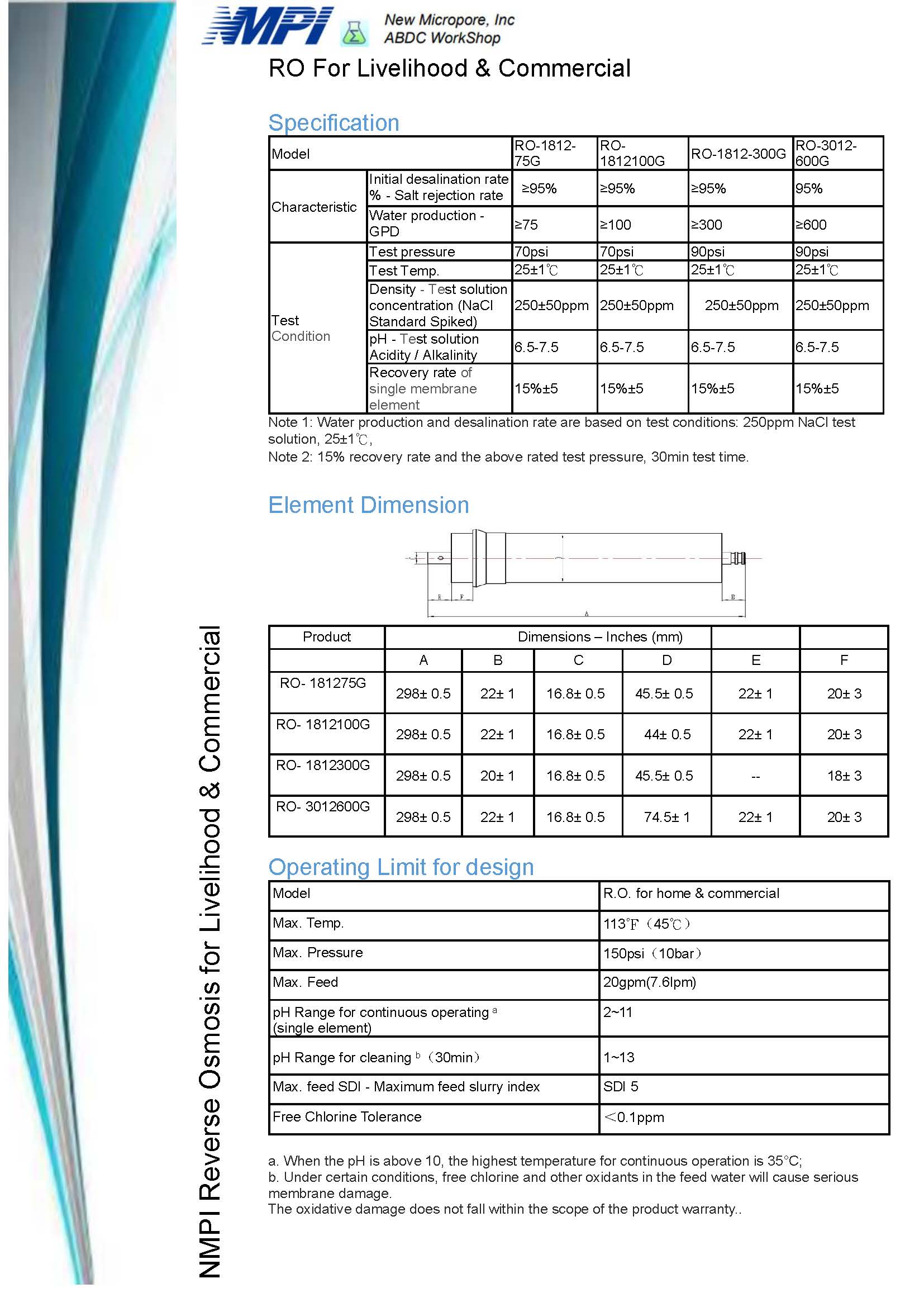

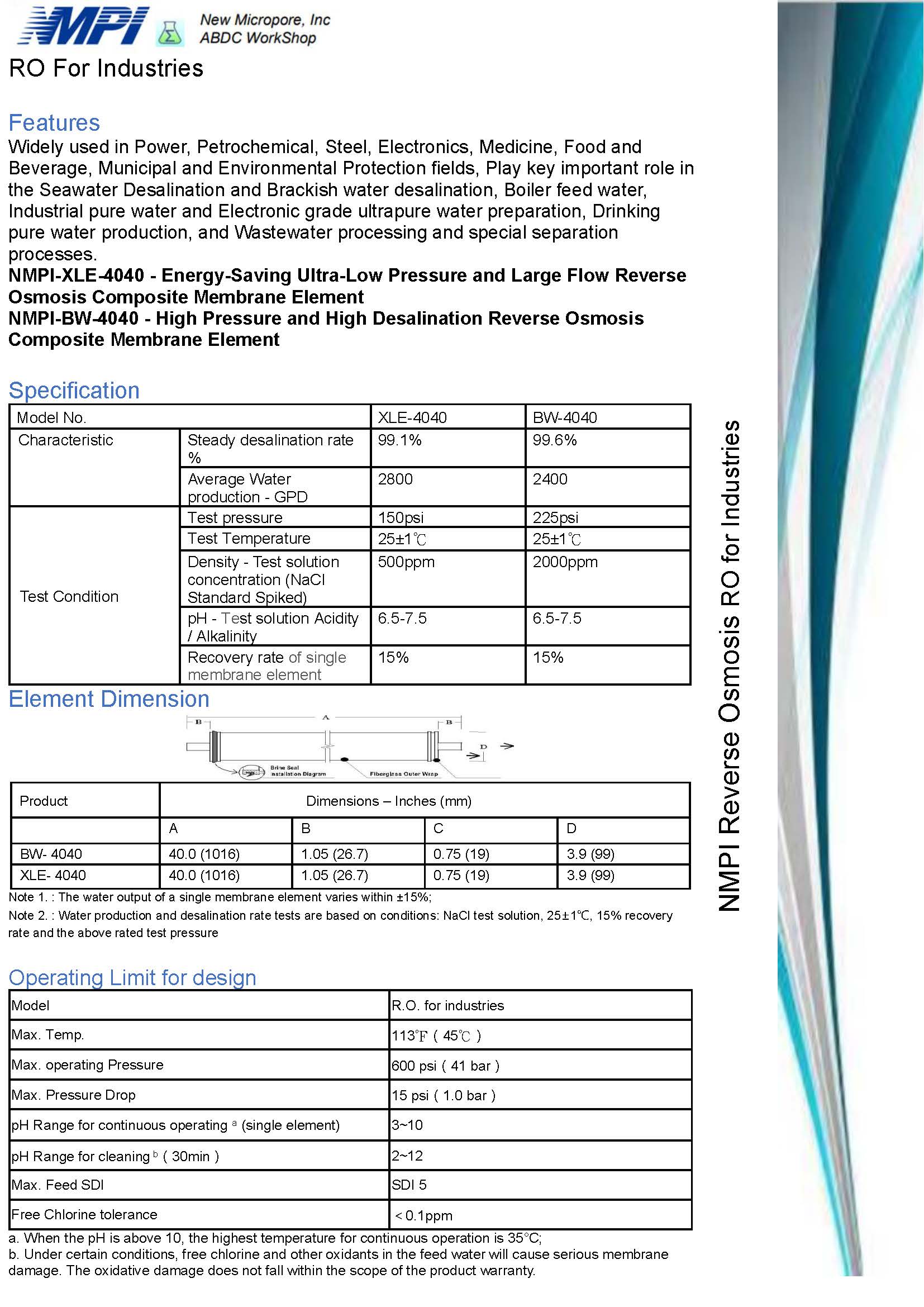

Ultrafiltration & Nanofiltrations

UF Series / Spiral-Wound / Submerged UF (S-UF) Flat Membrane Bio-Reactor System(MBR) Nano Filtration (NF Series)Reverse Osmosis Membranes (RO Series)Lab Scale Test Kit

Knowledge base :

Membrane separation processess, Pore size and selectivity, Ultrafiltration (UF)), Nanofiltration, Reverse Osmosis

Ultrafiltration for a swimming pool |

Membrane separation process have a very important role in the separation industry. Nevertheless, they were not considered technically important until the mid-1970s. Membrane separation processes differ based on separation mechanisms and size of the separated particles. The widely used membrane processes include microfiltration, ultrafiltration, nanofiltration, reverse

osmosis, electrolysis, dialysis, electrodialysis, gas separation, vapor permeation, pervaporation, membrane distillation,

and membrane contactors. All processes except for pervaporation involve no phase change. All processes except (electro)dialysis are pressure driven. Microfiltration and ultrafiltration is widely used in food and beverage processing (beer microfiltration, apple juice ultrafiltration), biotechnological applications and pharmaceutical industry antibiotic production,

protein purification), water purification and wastewater treatment, the microelectronics industry, and others. Nanofiltration and reverse osmosis membranes are mainly used for water purification purposes. Dense membranes are utilized for gas separations (removal of CO2 from natural gas, separating N2 from air, organic vapor removal from air or a nitrogen stream) and sometimes in membrane distillation. The later process helps in the separation of azeotropic compositions reducing the costs of distillation processes.

|

|

Pore size and selectivity

The pore sizes of technical membranes are specified differently depending on the manufacturer. One common distinction is by nominal pore sizee. It describes the maximum pore size distribution[4] and gives only vague information about the retention capacity of a membrane. The exclusion limit or "cut-off" of the membrane is usually specified in the form off NMWC (nominal molecular weight cut-off, orr MWCo, molecular

weight cut off, with units in Dalton). It is defined as the minimumm molecular weight of a globular molecule that is retained to 90% by the membrane. The cut-off, depending on the method, can by converted to so-calledd D900, which is then expressed in a metric unit. In practice the MWCO of the membrane should be at least 20% lower than the molecular weight of the molecule that is to be separated.

Using track etched mica membranes Beck and Schultz demonstrated that hindered diffusion of molecules in pores can be described by the Renkin equation.

|

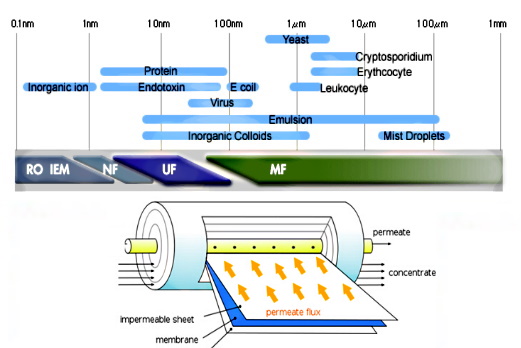

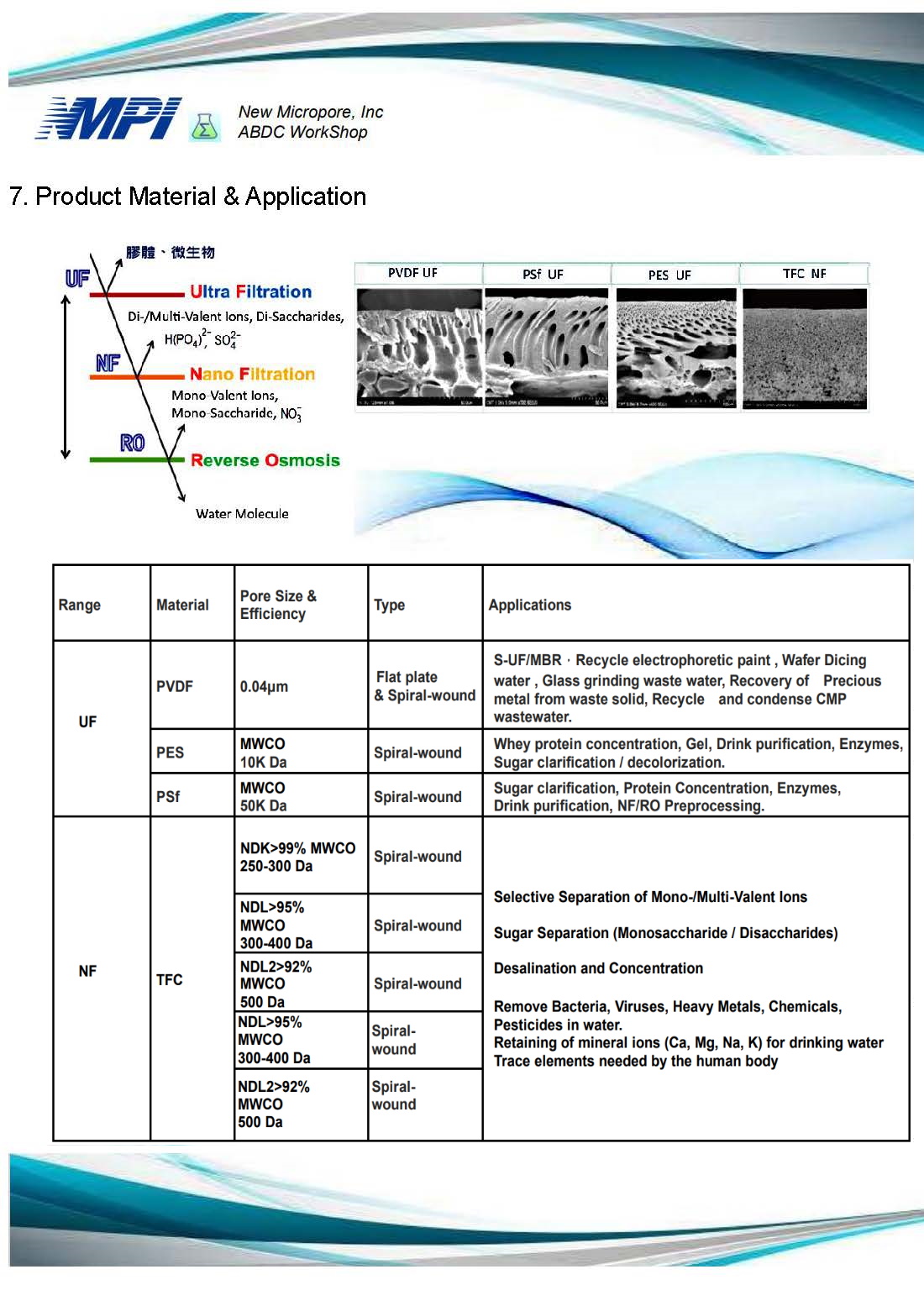

Ranges of membrane based separationss |

|

Filter membranes are divided into four classes according to pore size:

| Pore sizee |

Molecular masss |

Processs |

Filtration |

Removal off |

| > 10 |

|

"Classic" Filter |

|

|

| > 0.1 μm |

> 5000 kDa |

microfiltration |

< 2 bar |

larger bacteria, yeast, particles |

| 100-2 nm |

5-5000 kDa |

ultrafiltration |

1-10 bar |

bacteria, macromolecules, proteins, larger viruses |

| 2-1 nm |

0.1-5 kDa |

nanofiltration |

3-20 bar |

viruses, 2- valent ions |

| < 1 nm |

< 100 Da |

reverse osmosis |

10-80 bar |

salts, small organic molecules |

|

Diagram of cross-flow filtration

|

Cross-flow filtration

In chemical engineering, biochemical

engineering andd protein

purification, crossflow

filtration (also known ass tangential

flow filtration) is a type off filtration (a

particularr unit operation). Crossflow filtration is

different fromm dead-end filtration in

which the feed is passed through aa membrane or

bed, the solids being trapped in thee filter and

thee filtrate being

released at the other end. Cross-flow filtration gets its name because the majority of the feed flow travels tangentially acrosss the

surface of the filter, rather than into the filter.

|

|

Ultrafiltration (UF)is a variety off membrane filtration in which forces likee pressuree orr concentration gradients lead to a separation through aa semipermeable

membrane. Suspended solids andd solutes of highh molecular weightt are retained in the so-called retentate, while water and low molecular weight solutes pass through the membrane in thee permeate (filtrate). Thiss separation

process is used in industry and research for purifying and concentrating macromolecular (1003 - 1006 Da) solutions, especially protein solutions.

Ultrafiltration is not fundamentally different fromm microfiltration. Both of these separate based on size exclusion or particle capture. It is fundamentally different fromm membrane gas separation, which separate based on different amounts off absorption and different rates off diffusion.

Ultrafiltration membranes are defined by thee molecular weight cut-off (MWCO) of the membrane used. Ultrafiltration is applied in cross-flow or dead-end mode.

Using track etched mica membranes Beck and Schultz demonstrated that hindered diffusion of molecules in pores can be described by the Renkin equation.

|

Hollow fibre modulee |

|

Thee process characteristics of a UF system are highly dependent on the type of membrane used and its application. Manufacturers' specifications of the membrane tend to limit the process to the following typical specifications:

|

Hollow Fibree |

Spiral-woundd |

Ceramic Tubularr |

Plate and Framee |

| pHH |

2–133 |

2–111 |

3–77 |

|

| Feed Pressure (psi) |

9–155 |

<30–1200 |

60–1000 |

|

| Backwash Pressure (psi) |

9–155 |

20–400 |

10–300 |

|

| Temperature (°C)) |

5–300 |

5–455 |

5–4000 |

|

| Total Dissolved Solids (mg/L) |

<10000 |

<6000 |

<5000 |

|

| Total Suspended Solids (mg/L) |

<5000 |

<4500 |

<3000 |

|

| Turbidity (NTU) |

<155 |

<11 |

<100 |

|

| Iron (mg/L) |

<55 |

<55 |

<55 |

|

| Oils and Greases (mg/L) |

<0.11 |

<0.11 |

<0.11 |

|

| Solvents, phenols (mg/L) |

<0.11 |

<0.11 |

<0.11 |

|

|

|

Nanofiltration is a membrane

filtration-based method that usess nanometerr sized

through-pores that pass through the membrane. Nanofiltration membranes have pore sizes from 1-10 nanometers, smaller than that used in microfiltration andd ultrafiltration,

but just larger than that in reverse osmosiss. Membranes used are predominantly created from polymer thin films..[1] Materials

that are commonly used includee polyethylene terephthalate or metals such ass aluminumm.[2] Pore

dimensions are controlled by pH, temperature and time during development with pore densities ranging from 1 to 106 pores per cmm2.

Membranes made from polyethylene terephthalate and other similar materials, are referred to as "track-etch" membranes, named after the way the pores on the membranes are made..[3] "Tracking" involves bombarding the polymer thin film with high energy particles. This results in making

tracks that are chemically developed into the membrane, or "etched" into the membrane, which are the pores. Membranes created from metal such as alumina membranes, are made by electrochemically growing a thin layer of aluminum oxide from aluminum metal in an acidic medium.

Historically, nanofiltration and other membrane technology used for molecular separation was applied entirely on aqueouss systems. The original uses for nanofiltration were water treatment and in particularr water softening. Nanofilters can "soften" water by retaining scale-forming, hydrated divalent ions (e.g. Ca2++, Mg2++) while passing smaller hydrated monovalent ions.[4]][5]

In recent years, the use of nanofiltration has been extended into other industries such as milk and juice production. Research and development in solvent-stable membranes has allowed the application for nanofiltration membranes to extend into new areas such ass pharmaceuticals, fine chemicals, and flavour and fragrance industries.[4]

Range of applications

|

Industry

|

Usess

|

|

Fine chemistry and Pharmaceuticalss

|

Non-thermal solvent recovery and managementt

Room temperature solvent exchangee

|

|

Oil and Petroleum chemistry

|

Removal of tar components in feedd Purification of gas condensatess

|

|

Bulk Chemistry

|

Product Polishingg, Continuous recovery of homogeneous catalystss

|

|

Natural Essential Oils and similar productss

|

Fractionation of crude extractss

Enrichment of natural compounds Gentle Separationss

|

|

Medicinee

|

Able to extract amino acids and lipids from blood and other cell culture..

|

|

Mechanisms through

which solutes in nanofiltration transport through the membrane.. |

Reverse osmosis production train, North Cape Coral

Reverse Osmosis Plant |

Reverse Osmosis (RO)is a water purification process that uses a partially permeable membrane to

separate ions,

unwanted molecules and

larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic pressure,

a colligative property that

is driven by chemical potential differences

of the solvent, a thermodynamic parameter.

Reverse osmosis can remove many types of dissolved and suspended chemical species as

well as biological ones (principally bacteria) from water, and is used in both industrial processes and the production of potable water.

The result is that the solute is

retained on the pressurized side of the membrane and the pure solvent is

allowed to pass to the other side. To be "selective", this membrane should not allow large molecules or ions through the pores (holes),

but should allow smaller components of the solution (such as solvent molecules, i.e., water, H2O)

to pass freely..[1].

|

Leading with Quality, Performance and Cost

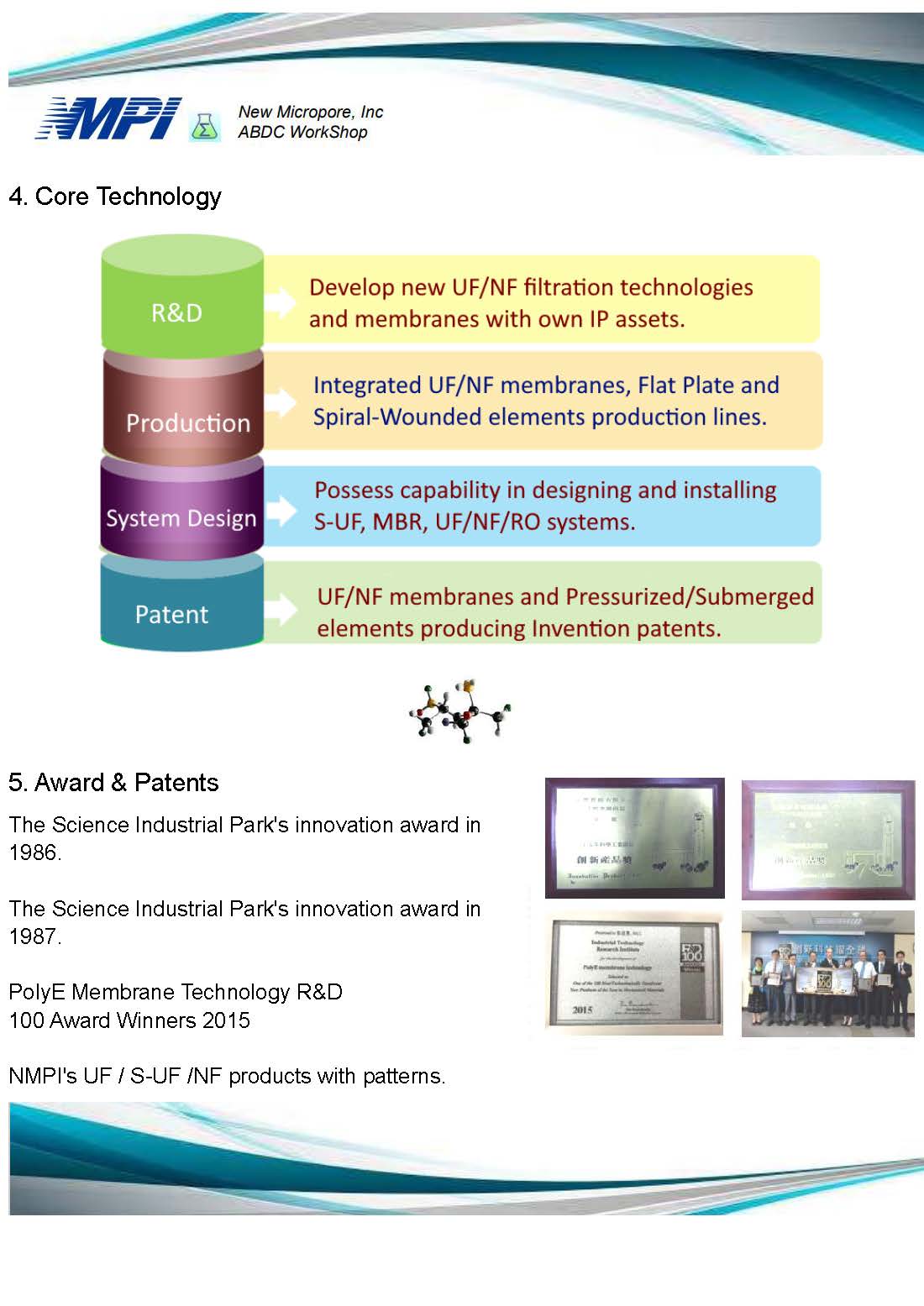

Established in 1984, the New Micropore Inc.(NMPI) is dedicated to the R&D and Manufacturing and Innovation of the Ultrafiltration, Nanofiltration, and Reverse Osmosis membrane materials and various modules, filtration equipment systems and related products. providing customers with Pure water, Material Concentration, Separation and Purifications, Water Recycling, Wastewater treatment, membranes and systems, NMPI has decades of operating experiences in basic membrane materials and membrane equipment applications, adhering to the high quality requirements of the products with membrane material products produced in line with ISO9001. NMPI products are widely used in wide ranges of industries, as for Semiconductor, optoelectronics, electronics, Food, Biotechnology,

Public Engineering, Chemical industry and other fields. The products are diversified and sold all over the world, and have been well received by customers for many years. being an professional membrane material, equipment of total solutions provider with full range of services, with most helpful cooperation and development with all our customers and partners! NMPI develops new UF/NF filtration technologies and membranes with own IP assets, obtaining invention patents in producing UF/NF membranes and Pressurized or Submerged elements. NMPI possess complete capability in designing and installing S-UF, MBR, UF/NF/RO systems, and have built integrated production lines for UF/NF membranes, Flat Plate and Spiral-Wounded filtration elements and modules, . ......

NMPI CatalogueDeployed in various liquid separation, filtration, and purification processes, our routinely produced UF / NF / RO filtration element / module / equipments developed by NMPI are suitable for your applications for most requyirements, where customized design, priduction and implemntation are available for dedicated optimization purposes.

INDEX of NMPI Catalog

|

|