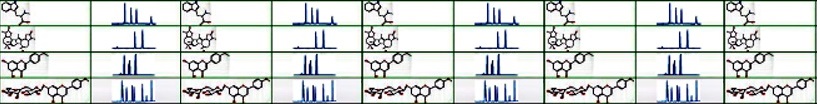

|

|

Preparative Chromatography Systems DAC/M/HPLC/SAC/Gels |

|

|

|

|

CPhI China 2016 & Circumstance

(More Photos ... )

CPhI China 2015 & Circumstance

(More Photos

... )

2016 Southwest Region Biopharmaceuticals separation and purification technology

exchange seminar

(More Photos ... )

Leading with Quality, Performance and Cost :

We(Gelai_ABDC) are a global technology and

marketing team, with continuous efforts for more than 20 years ,

cooperating

seamlessly with all users in research institutions, industry, universities, for

their practical demands, and successfully developed DAC M/HPLC systems with

independent intellectual properties.

http://www.cdgelai.com/

http://www.chromnet.net/

|

|

1. More than >500 large

& Total > 2100 systems

installed, with abundant high throughput,

high efficiency large-scale DAC-HPLC experiences for more

than 15 years. |

|

|

2. Dedicated optimized Dynamic Axial

Compression Column(DAC Column) design,

approaching high resolution from the analytical HPLC

column. |

|

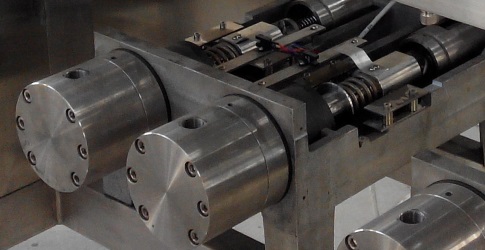

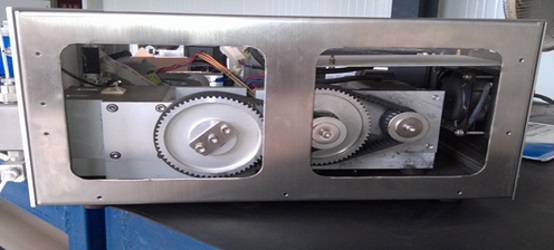

3. Middle/High pressure Gradient Pump(M/HPLC

Pumps) capability,

with

precision screw module that promise very stable & precise mobile phase output. |

|

4. 1/2 to 2/3 cost, very helpful to

optimized budgets controls, especially for cost management for acquiring more

equipment. |

|

Product catalogue

User Manual_Preparative_HPLCPump_GLP3000-500ml_ChineseToEnglish.pdf

User Manual_Preparative_HPLCPump_GLP3000-500ml_ChineseToEnglish.pdf

User Manual_UV Spectrophotometric Detector_UV-3292_ChineseToEnglish.pdf

User Manual_UV Spectrophotometric Detector_UV-3292_ChineseToEnglish.pdf

User Manual_FractionCollector_GL-LF096_ChineseToEnglish.pdf

User Manual_FractionCollector_GL-LF096_ChineseToEnglish.pdf

User Manual_ChromatographyWorkStation_ChineseToEnglish.pdf

User Manual_ChromatographyWorkStation_ChineseToEnglish.pdf

User Manual_SAC_Column_ChineseToEnglish.pdf

User Manual_SAC_Column_ChineseToEnglish.pdf

User Manual_SAC500 ChromatographyColumnSystem_ChineseToEnglish.pdf

User Manual_SAC500 ChromatographyColumnSystem_ChineseToEnglish.pdf

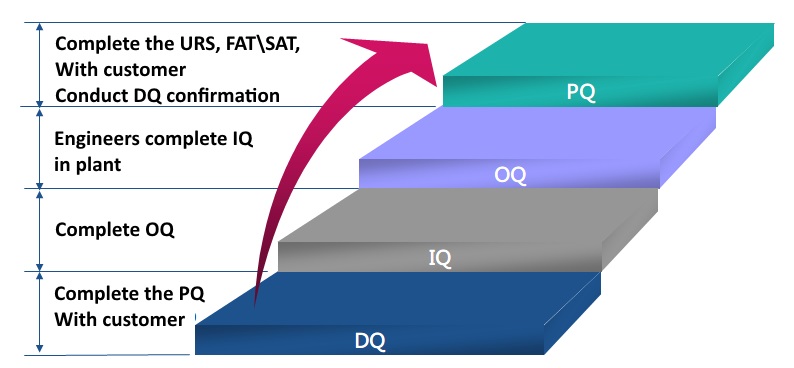

System Design Qualification &

Verification(DQ,IQ,OQ,PQ) :

Please contact for specific system configurations.

(Click

image for large images)mage for large images)

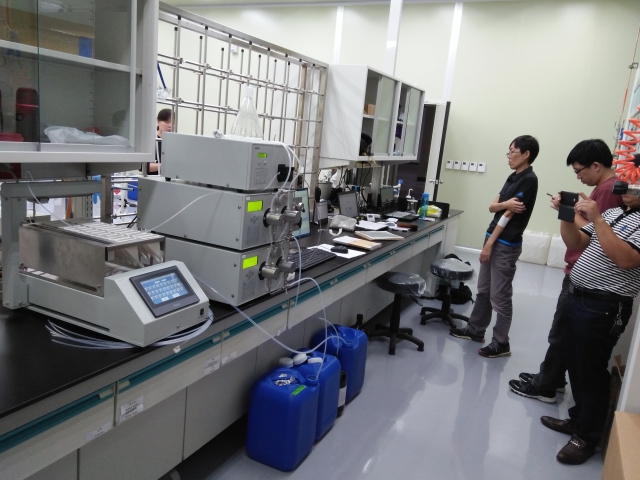

The Pump and Detector Assembling:

The DAC M/HPLC retains and scale-up the very

mature and stable separation technologies of the analytical High Performance

Liquid chromatography(HPLC) system, and has become the predominate purification

preparation methods with highest separation power and resolutions in many

fields, as biochemistry, biotechnology, pharmaceuticals, natural products,

organic synthesis, fine chemicals, preparation of standards, and food

ingredients fields, etc.

Factory Facility:

System Modules:

-

Diameter ID25.4mm, 41.4mm, 50mm, 77mm, 80mm,

100mm, unique semi-preparative/preparatory chromatography columns(prePacked

Column / SAC Column),

-

DAC-ID100mm, 150mm, 200mm, 400mm, 600m,

800m, 1000,1200mm, the Dynamic Axial Compression column systems(DAC Column)

-

GLP-100ml, 250ml, 500ml, 1000ml, 2000ml,

3000ml, 5000ml Preparative High-Pressure Gradient Solvent Delivering Pump

systems(M/HPLC Pumps)

and other ancillary products, forming a

complete set of chromatography systems from laboratory to mass

preparative

productions.

System Accuracy &

Optimizations:

Our Various types of accurate middle to high pressure Solvent Delivering

Pumps(M/HPLC Pumps), can respectively withstand nearly 6000-3000psi, with

extremely small flowing pulse <= 1Bar(0.1Mpa),

which means that the users can convert and scale-up most of the separation

conditions

form analytical HPLC to our preparative M/HPLC systems with DAC, SAC or pre-Packed columns.

Our DAC/SAC Columns is optimally designed with

patented Forced Fluid Path Distributing technology

both for the column inlet and outlet, making more uniform and stable fluid path

distributing.

As the most helpful technology and business

partner for advanced technology manufacturers and laboratories,

We offer the ability to closely integrate customized developments.

We develope and manufacture preparative

HPLC/MPLC systems with same or better functionality and durability, saving

nearly 1/2-2/3 cost for equipments and consumables.

Two Axial Compression Column Technologies :

1.Dynamic Axial Compression:

The column and packing module are intergarted and work

together.

The piston head

pressure is monitored continuously in chromatography process, and will be

dynamically pressed tighter along the axis in

response and sensitive to minor pressure declines.

It is an optimized closed loop feedback

control system that will always maintains uniform

column resolution and performance, until the packing material is contaminated

after a long period of time.

2. Static Axial Compression:

The column and packing module(Packing Station) are seperated and work

independently.

The

column is first filled with

chromatography media packing material in the

Packing Station

with required pressure.

The column is then taken apart from the Packing Station,

and

connect to a configured chromatography system to work.

In response to pressure declines, the column piston head

could be re-pressured manually by

a planetary gear reducer or by the extension of a build-in spring.

The planetary gear reducer column has no stroke limit and material fatigue

drawbacks as that from the build-in spring type column, and does not degrade the

column resolution and performance by itself.

The Advantages of our DAC Columns :

1. The solvent

manipulation and gradient alternations all may dynamically cause the packing

particles to swell or shrink. And hence only the DAC can response rapidly to

recover from these fluctuations.

2. The DAC always dynamically maintains pressure equilibrium in axial direction

of the DAC column.

When the packing bed loosing occurs, the piston will be

pressured immediately to maintain homogenous column packing bed to maintain

stable column efficiency, and to prevent peak from tailing and shape changes.

3. The DAC

mechanism is more stable and reproducibable, and produces best product purity

and recovery rate.

4. The column packing bed can sustain stable in very long

term,

5. Routine column inner diameter from 50mm to reache a

1200mm maximum.

6. Small

packing sphere sizes as 5 microns that will almost achieve the same separation

efficiency of the analytical columns.

7. The packing

functionality have been built in the DAC system for user's own packing in the

equipment location.

8. Composed of

durable parts for prolonged applications, including gas-driven magnification

pumps, durable transmission hydraulic oil, compression piston. etc.

Application consideration for SAC Columns :

1. In case that soft packing materials

or samples may be deformed or with properties variation under larger

pressure.

2. More than one column can be packed independly with one Packing Station that

is located in user or equipment manufacturer site, and can be connected independently to HPLC Pump systems for use.

Prominent Features

and Benefits of our SAC Column:

Gelai_ABDC_SAC_Introductions.pdf

Gelai_ABDC_SAC_Introductions.pdf

1. Global leading design and approach for

the embeded manual pressing device that performs advanced axial compression

functionality.

2. The Surface Finish of our column wall is

better than ≥

▽ 12 (ie, Ra ≤ 0.25μm) that ensuring

very good column concentricity(0.2μm), and is better than similar global

products.

We continuously and routinely cooperate with domestic and global institutions

for advanced technologies, such as the concentricity and precision polishing

technologies for column inner wall from key military units.

These efforts ensures out excellent product stability and performance.

3. Capabilities to maintain sufficiently

high internal pressure that prevent the sharp decline in column efficiency

caused by the collapsing of column bed.

In specific cases if the column bed have loosed and collapsed, the original

column pressure and column efficiency can be be restored without any tools by

just manually and gently twist on the top pressing device.

4. The column efficiency is high enough to

makes it easy to achieve linear amplification from analytical to preparation

scales. The unique column-end distribution piece design, have provided more

uniform chromatographic process for samples, with more symmetrical peak shapes.

5. With removable and both normal and

reverse directions applicable feasibilities that make user re-filling very easy.

The durable life time is much longer than other prepared column that are

implemented with fixed flange sealing mounting.

6. Eliminate the drawbacks of Spring compressed type SAC columns, such as lower

performance, large volume, and non-linear pressure decline along stroke

and spring fatigue along times.

7. The performance of SAC column is generally equal to that of DAC column in low ID ranges(<=80mmID).

8. We provide SAC column

packing services in our factories with very affordable costs.

NOTE: We can also, according to customer

requirements, manufacture customized or specialized columns that are packed with

user specified packings from various sources as Kromasil, HyperSil, Fuji, etc.

We also provide re-packing and other services for preparative columns provided

from customers .

Our Routine

SAC Specifications:

|

(1 inch) ID25.4mm *450mm

|

|

(2 inch) ID50mm *450mm |

|

(3 inch) ID80mm *450mm

|

|

(4 inch) ID100mm *450mm

|

|

Customized sizes & packings |

Using same pumps to covering from SAC to DAC columns:

The

Transmission Mode of our pump systems features ± 1% Flow Accuracy or even better

to ± 0.3% in the full Flow Flow range. This prominent perpormance makes it

possible for our users to select larger pumps(for example: 500ml/min) without

minor

additional cost in the begining for thier SAC columns(it may need only <= 100ml/min

pump),

and in the future, the pumps may

switch to connect to

a 100-150mm DAC columns as well.

GL3100 Laboratory Purification system

Binary High Pressure Gradient Elution

(Option up to Quaternary Gradient--4 pumps)

|

Pump System:

|

2 sets |

|

Flow range :

|

0-100ml/min

|

|

Solvent Delivering:

|

Screw drive, dual piston |

|

Pump Material:

|

316L stainless steel |

|

Maximum working pressure:

|

6000Psi |

|

Flow Accuracy:

|

± 1% Flow |

|

Repeatability:

|

RRSD≤0.5% |

|

|

|

|

Detector:

|

190-740nm |

|

Band:

|

190-740nm

|

|

Light source:

|

Deuterium lamp, Tungsten lamp

|

|

Wavelength accuracy:

|

± 1nm |

|

BandWidth:

|

8nm

|

|

Noise: 2 × 10-5AU

|

(254nm@1mL/min@methanol) |

|

Drift: 15 ×10-5AU/h |

(254nm@1mL/min@methanol) |

|

Detection Limit: 5 × 10-9g/mL

|

(254nm@1mL/min@methanol@naphthalene standard) |

|

|

|

|

Injector:

|

Manual injector with 10ml Loop |

|

|

|

|

Column:

/td>

|

25.4mm-80mm prePacked columns |

|

Sieve aperture:

|

3-5um |

|

Column Material:

|

316L stainless steel |

|

Stream Distributer:

|

Multi-point forced distribution |

|

Column Inner Wall Finish:

|

≤0.25μm(Surface Roughness) |

The system configuration can be customized: configurated

sizes can be adapted from milligram to gram-scale for research development and

production needs.

One of the new drug R&D laboratories

customer example:

Pilot scale purification system

Binary/Tertiary High/Middle Pressure Gradient Elution

|

Pump System:

|

3 sets |

|

Preparation DAC Column:

|

1 set

|

|

Detector:

|

1 set

|

|

The system configuration can be customized: configurated sizes are sutable

for required production scale from gram to kg-class level.

|

|

Solvent Delivering mode:

|

Dual piston reciprocating pump |

|

Transmission mode:

|

Screw drive

|

|

Pump Material:

|

316L stainless steel

|

|

Specifications and pressure range:

|

|

|

100ml/min pump head

|

6000psi

|

|

250ml/min pump head

|

5000psi

|

|

500 mL/min pump head

|

3500 psi

|

|

1000ml/min pump head

|

2000psi

|

|

2000ml/min pump head

|

1500psi |

|

5000ml/min pump head

|

1500psi

|

|

10000ml/min pump head

|

1500psi

|

|

20000ml/min pump head

|

1500psi |

The Transmission Mode:

Since we have integrated the international high-end

Precise Screw Transmission Mechanism that is adopted only in the high-end

instruments(the Varian(USA) also use this mode) with our own triple Close Loop

Servo Mechanism.

OOur pump systems have achieved smallest fluctuation of flow rate baseline than

other sources.

The Good system reproducibility, and low flow pulse features, is significantly

different from that of the Cam Transmission Mode from most other suppliers, and

have great advantages in terms of impulse control and precision, especially in

the high purity and gradient preparation practices.

|

Gelai Screw transmission |

|

|

|

|

Varian(USA) Screw transmission

|

Cam transmission |

|

|

Dynamic Axial

Compression system(DAC)

The DAC system is composed of column cylinder, Hydraulic cylinder, piston and

pneumatic motor, is an integrated column system with packing capability. The

users could option to equip with automatic homogenizing cans, moving trays and

other configurations.

There are 150mm, 200mm, 300mm, 450mm, 600mm, DAC 800mm etc. DAC column cylinder

in diameters.

|

DAC_ID_50mm |

DAC_ID_150mm

|

DAC_ID_500mm |

DAC Colum Miller

|

|

|

|

|

Advantages of the Dynamic Axial Compression system(DAC)

1.Pressure Tolerance and Adhesiveness:

Realize the inner surface

finish of ≥▽12, namely the Surface Roughness ≤0.25μm; the concentricity of the

piston and cylindrical reach 0.2um, the piston is sealed with imported

oblique-spring seals. These features enable the column tolerance to 6000psi high

pressure without the risk of leakage, and without wearing for 50 repeatedly

filling.

2. The Uniformity and

Reproducibility of stream distribution:

Both the DAC Column inlet

and outlet ends are optimally adopted with our patented

Forced Fluid Path

Distributing technology, that enable the sample solution and mobile phrase

stream to uniformly flow

through the column, and have good peak symmetry.

3.

The packing process is easy to learn

, that uses a short time with low air compressor demand.

90 kg pressure within the cylinder can be packed using 6kg air pressure.

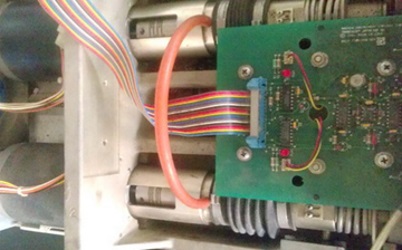

Detector system

|

|

|

Wavelength range |

190 ~ 740nm |

|

Cut-off filter |

370nm |

|

Light sources

|

Deuterium lamp, Halogen(optional) |

|

Wavelength accuracy |

± 1nm |

|

Noise |

2 × 10-5AU(254nm@1mL/min@methanol) |

|

Drift: |

15 ×10-5AU/h(254nm@1mL/min@methanol) |

|

Detection Limit

|

5 ×

10-9g/mL(254nm@1mL/min@methanol@naphthalene standard) |

Examples of customers:

|

A FDA-approved peptide workshop

|

|

|

|

|

GMP certificated peptide workshop

|

A new drug R&D center & A chemical plant |

|

|

|

GMP compliance system hardware |

|

|

-

Material Compliance:

Pump head, pipelines, column cylinder that

direct contact with the drug, are 316L stainless steel, and the other main

support structures are 304 stainless steel, with the provision of material proof

available.

-

Easy to clean,

without dead corner space: Corner

space positions in the system are arc designed, that is easy to clean and

resistant to all types of cleaning agents and disinfectants, without corrosion.

-

Stable: Good

equipment performance and system reproducibility.

|

|

|

|

|

Complete the URS, FAT\SAT, With customer.

Conduct DQ confirmation.

Engineers complete IQ in plant.

Complete OQ.

Complete the PQ With customer. |

|

System Warranty: Two years; Deuterium lamp & Check valve: 1 year,

with normal operation after installation.

Also Welcome

to our World Culture Resources

|