Pesticide Analysis Using QuEChERS

Extraction:

A Comparison of Manual and Automated Approaches |

|

|

使用QuEChERS萃取的農藥分析:手動和自動方式的比較 |

|

|

By Tyler Trent and Tom Hartlein (中文翻譯:ABDC) |

|

Abstract/Introduction

摘要/簡介

QuEChERS is a Quick-Easy-Cheap-Effective-Rugged-Safe extraction method

that has been developed for the determination of pesticide residues in

agricultural commodities.

QuEChERS

是一個集合 快速-簡便-廉價-高效-耐用-安全等特點的萃取方法,

已經被發展用來做農產品裏的農藥殘留的測定.

The European

Standard is Method EN 15662:2008. While originally developed for plant matrices,

the technique has since been adapted to be used

in several applications and in many additional matrices.

歐洲標準是方法EN15662:2008.

雖然最初是為植物性基質而開發,這項技術已經被調整使其用於幾個應用以及很多增加的基質.

The rise in popularity of the technique

and the increase in sample testing loads have lead to automation as a possible

solution to increase productivity.

這項技術已普及化的崛起以及抽樣檢測負載的增加,

導致自動化成為一種可能提高生產效率的解決方案.

The method, as mentioned, is a simple and

fast extraction when compared to traditional semi volatile extraction

techniques.

這項方法,

如前所述,

相對於傳統的半揮發性萃取技術是一種簡單, 快捷的萃取.

However, it still requires dedicated

manpower, sample prep equipment, manual spiking, manual pipetting, and a wide

range of reagents and consumables.

但是,它仍然需要專門的人力,樣品製備設備,手動摻入標準品,手動移液,以及大範圍的試劑和耗材.

The analytical and practical challenges

of automating this technique will be discussed and a comparison of extraction

recoveries achieved both manually and by automation will be evaluated.

將這種技術加以自動化的分析和實務上的挑戰將被討論,

以及經由人工和自動化達到的回收率的比較將被評估.

Data will be presented that justifies

automation as a possible solution to increase sample throughput, reduce costs,

and improve the accuracy and precision of the extraction.

證明自動化可作為一種提高樣品通量, 降低成本,

增進萃取的準確度和精密度的可能解決方案的數據將被呈現.

Results/Discussion

結果/討論

Solvent Addition, Spiking and Preservation

Liquid handling is accomplished with a dual syringe

drive system, one equipped with a 25 mL syringe to handle

larger solvent volumes, and a 250 μl syringe to handle

smaller spiking volumes.

手動摻入標準品, 手動移液添加溶劑, 摻入標準品,

和保存液的操作處理是由一個雙注射筒驅動系統所完成,

一個配備25毫升注射筒驅動用於操作處理較大的溶劑量, 以及250微升注射筒用於操作處理較小的標準品摻入量.

Multiport ceramic distribution valves allow for the

user to connect multiple extraction solvents and spiking solutions to the

fluidic pathway without cross contamination.

多位置陶瓷分配閥允許用戶在連接多種萃取溶劑和各摻入標準品到這個流體通路時沒有交叉污染.

The syringe drive and valve are chemically compatible with virtually any

extraction solvent; but this study validated the accuracy and precision of

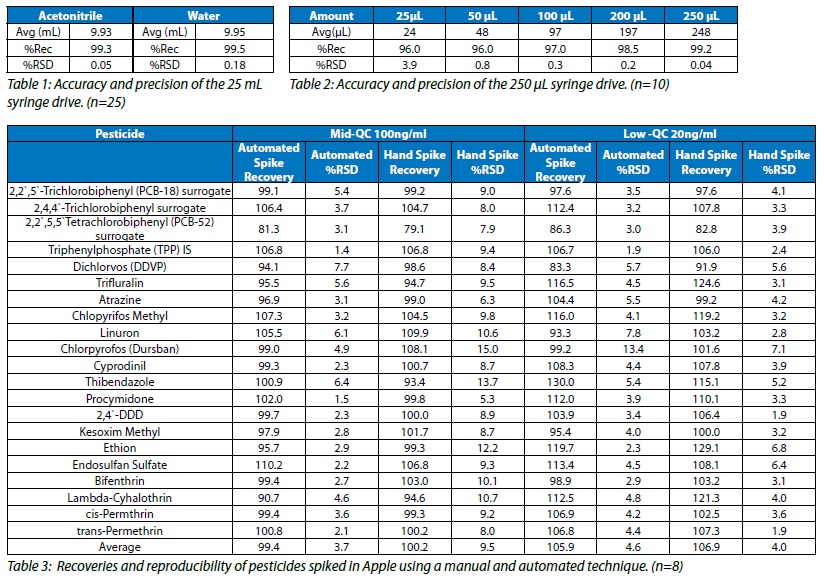

delivering water and acetonitrile.(Table 1)

注射器驅動器和閥門與幾乎所有的最萃取溶劑是化學相容的.但本項研究對輸送水和乙腈的準確度和精度進行了確效(表1)

The system was confirmed to deliver within 1% accuracy and have

repeatability of less than 1%RSD.

此系統確認具有1%以內的輸送精度,並具有小於1%RSD的可重複性.

The system can be programmed to deliver spike volumes of 25 μl, 50 μl, 75

μl, 100 μl, 150 μl, and 200 μl.

此系統可以被程式化設定,

以提供25微升, 50微升, 75微升, 100微升, 150微升, 200微升的摻入標準品.

Accuracy and precision of the spike volumes were calculated and recorded.(Table 2)

Sets of extractions were performed manually and by automation at

two spiking levels.(Table 3)

摻入標準品的準確度和精確度進行了計算和記錄(表2) 萃取的組合操作,在兩個摻入標準品的濃度下以手動和自動來進行(表3)

Salt/Buffer Addition

鹽/緩衝液的加入

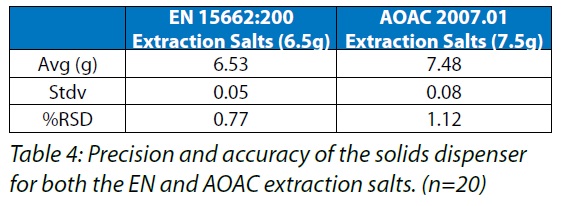

The salt delivery dispenser is equipped with a

“hopper” capable of holding over 2 Kg of premixed QuEChERS salts and the

container is sealed and kept under a blanket of dry gas during use.(Figure 1)

鹽的施放器配備了一個能夠容納超過2公斤的預混的QuEChERS鹽的"漏斗",而且這個容器被密封,並且在使用期間以乾燥氣體的夾套保持.(圖1)

Figure 1: Salt dispenser equipped with gravity fed hopper

圖1: 鹽的施放器配備了重力給料漏斗

The volume delivered can be adjusted to accommodate a delivery of between

4-10 g of salts. Tests were performed to confirm the precision and accuracy of

the salt dispenser.

輸送的體積可以調整,以適應4-10克之間的鹽的輸送.進行試驗以確認施放器的精密度和準確度.

The volume of the rotor was set to dispense 6.5g (EN15662:2008) and 7.5 g

(AOAC2007.01) of the salts and the dispenser was programmed to deliver 25 doses.

The doses were evaluated for accuracy and precision.(Table 4)

轉子的體積被設定為施放6.5克(EN15662:2008)和7.5克的鹽(AOAC2007.01),

程式設定施放器施放25劑.這些劑量進行了準確性和精確度的評估(表4)

Mechanical Mixer

機械混合器

There are several advantages to automating the mixing step, as well as the

dSPE cleanup portion of the extraction.

混合步驟的自動化有幾個優點,包括萃取中的dSPE的淨化部分

Besides the obvious labor saving, employing a

mechanical mixer for the QuEChERS extraction eliminates the variation of the

shaking techniques of different analysts, and improves the sample interaction

with the extraction solvents due to a more rapid and vigorous mix.

除了明顯的勞力節省,

採用機械混合器於QuEChERS萃取,

消除了不同的分析人員的震動技術的差異,

由於更迅速和激烈的混合,

增進了樣品與萃取溶劑交互作用.

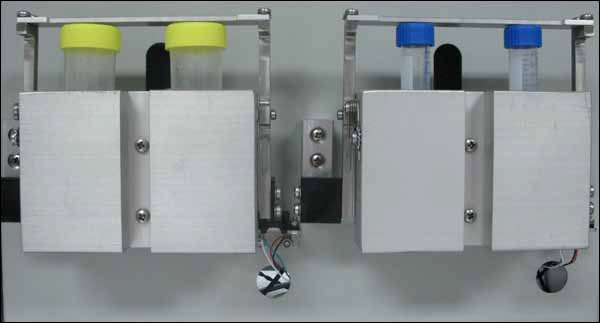

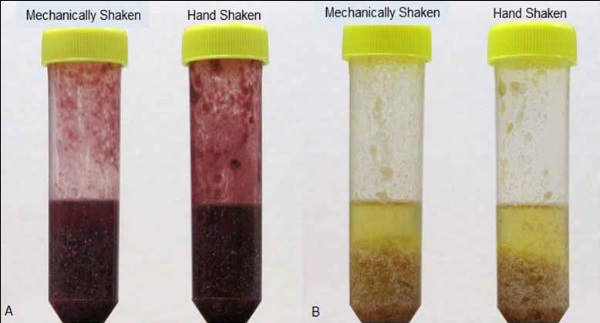

The automated shaker mechanism is capable of mixing up to 2-50 mL

centrifuge tubes and 2-15 mL centrifuge tubes simultaneously.(Figure 2)All

matrices that were mechanically mixed were equal to or better than samples that

were manually shaken.(Figure 3)

自動搖動機構是能夠同時混合到2-50毫升的離心管,

以及2-15毫升離心管(圖2) 所有用機械混合的基質,是相等於或比手動振盪的樣品更好(圖3)

Figure 2: Mechanical shaker

圖2:機械振盪器

Figure 3: Mechanical and hand shaken samples. - A:

Blackberry, B: Apple

圖3:機械及手動振盪樣本 - A:黑莓, B:蘋果

Several experiments were performed to confirm the reproducibility and

efficiency of the mixer. In the first experiment, an apple matrix was manually

spiked with a 50 ppb pesticide spiking solution.

進行幾個實驗以確認此混合器的再現性和效率.在第一個實驗中,

一個蘋果基質,

以手工摻入50ppb的農藥標準品溶液.

The samples were then extracted following the EN 15662:2008 extraction

method parameters. The extractions were performed using both a manual shaking

technique and the mechanical shaker for the mixing steps of the method.

然後按照

EN15662:2008的萃取方法的參數萃取樣品.同時使用的手動搖動技術和機械振盪器於方法中的混合步驟, 以進行樣品的萃取.

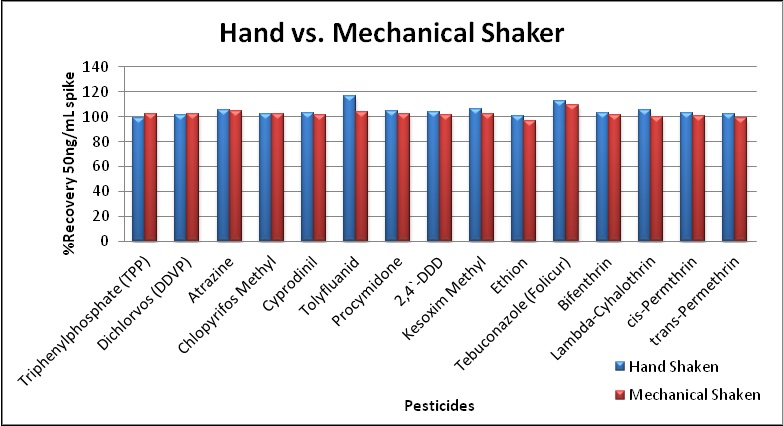

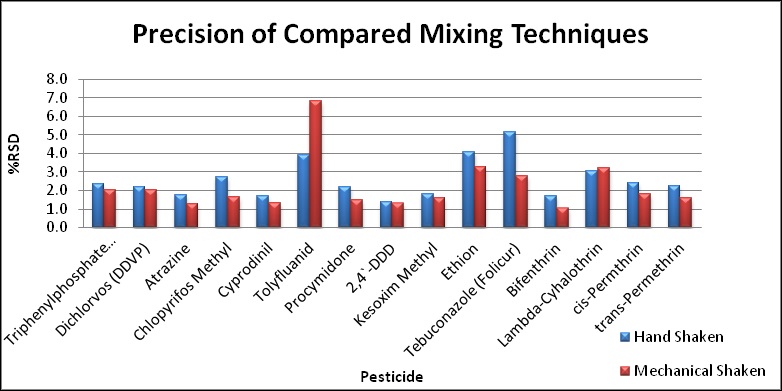

The sample extracts were analyzed and the spike recoveries were compared

for accuracy and precision.(Graphs 1-2)

樣品萃取液進行了分析,

以及比較了摻入標準品的回收率的準確度和精密度.(圖1-2)

Graph 1: Pesticides recoveries for 50 ppb

spiked apple matrix.

圖1:摻入50ppb標準品的蘋果基質的農藥的回收率

Graph 2: Precision of the mechanical shaker.

圖2:機械振盪器的精密度

Graph 1: Pesticides recoveries for 50 ppb spiked apple matrix.

Graph 2: Precision of the mechanical shaker

Automated Pipetting

自動移液

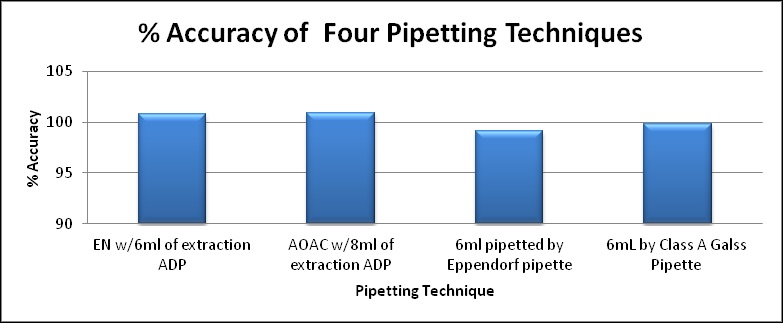

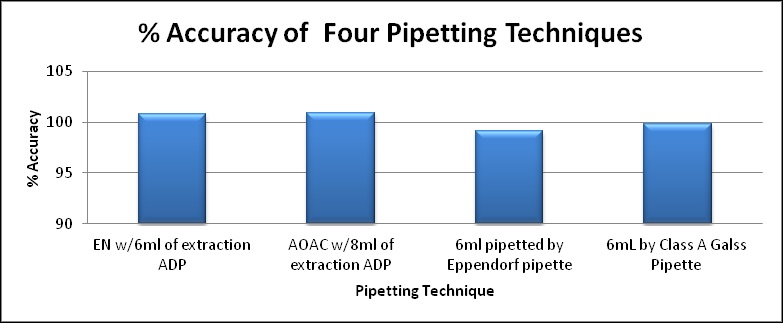

Experiments were conducted to evaluate the accuracy and precision of

robotically pipetting acetonitrile from a 50 mL centrifuge tube containing a

QuEChERS extract and dispensing it into a 15 mL centrifuge tube containing dSPE

cleanup media.

進行機械自動化地從含有QuEChERS萃取的50毫升離心管吸取乙腈,

施放到含有dSPE淨化媒介的15毫升離心管的準確度和精密度的評估實驗.

Additionally, aliquots were pipetted from the dSPE

cleanup vials and dispensed into a final screw cap storage vial to simulate the

two pipetting processes involved in the QuEChERS extraction.

此外, 從DSPE淨化小瓶吸取若干等分,

施放到最終的螺旋蓋儲存小瓶來模擬參與的QuEChERS萃取的兩個移液過程.

Automating the pipetting process for QuEChERS

samples is challenging due to the multi-layered matrix which could plug the

pipette tips. 由於多層基質可能堵塞移液管尖, QuEChERS樣品的自動化移液過程是具有挑戰性的.

To overcome this issue, a three prong approach was taken to ensure

accuracy, repeatability and reliability in the pipetting process.

為了克服這個問題,

採用三個同時運用的方法以確保移液過程中的準確性,

可重複性和可靠性.

First, through the use of our patent pending

VialVision(patent pending) system we are able to accurately determine the volume

of liquid that is available for aliquoting.

首先, 經由使用我們的專利申請中的 VialVision系統(專利申請中),

我們能夠準確地確定可用於分裝的液體體積.

Secondly, through the use of a conductive pipette tip we are able to

accurately detect the top layer of the extract. This allows us to determine the

exact depth at which pipetting can begin.

其次,經由導電性移液管尖的使用,我們能夠精確地檢測到萃取物的頂層.

這使我們能夠確定可以開始進行移液吸取的準確深度.

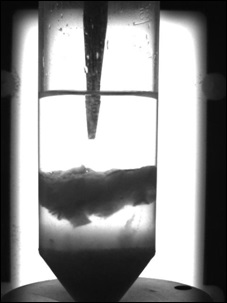

Lastly, by programming the robotic ADP probe to

follow the liquid down at a controlled speed during the pipetting process we can

reliably take the aliquot without fear of disturbing the underlying layer of the

sample matrix.(Figure 4)

最後, 經由程式控制機器自動化的ADP探頭使其在移液過程中, 以受控制的速度跟隨液體往下,我們可以可靠地取得等分試樣,

而不用擔心干擾樣品基體的襯底層的(圖4)

Figure 4: The ADP

during the pipetting process.

圖4:在移液過程中的ADP.

The appropriate amounts of sample, acetonitrile, and extraction salts were

added to the 50 mL centrifuge tubes. They were then shaken and spun down in a

centrifuge. 6 mL (EN 15662:2008) and 8 mL (AOAC 2007.01) aliquots were taken

from the 50mL extraction tubes and were transferred into empty extraction vials.

加入適量的樣品, 乙腈和萃取用的鹽到50mL離心管中.然後將它們振盪並且在離心機中離心下來.從50毫升萃取管取6毫升(EN15662:2008)和8毫升(AOAC2007.01)等分試樣,並且轉移到空萃取小瓶中.

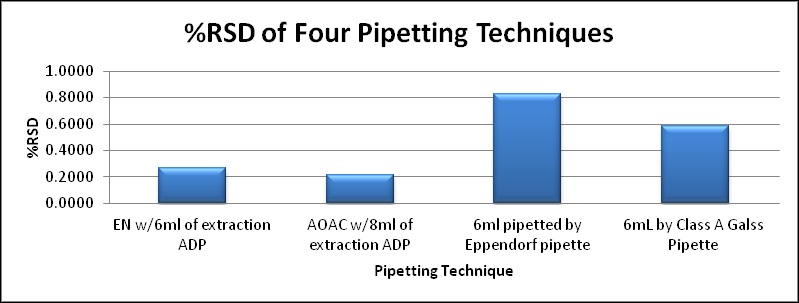

Graphs 3 illustrates the precision of the pipetting

process using both the ADP to pipette the aliquots and by pipetting manually

from the extraction tubes. The accuracy of the automated ADP technique was then

compared to two different styles of manual pipetting.(Graph 4)

圖3示出了使用

ADP以吸取等分試樣以及經由從萃取管手動移液兩者的精度.然後,自動ADP技術的精度再與兩種不同的方式的手動移液進行比較(圖四).

Graph 3: Pipetting precision of manual and

automated

pipetting techniques. (n=10)

圖3:手動和自動移液技術的移液精度.(N=10)

Graph 4: Pipetting accuracy using manual and

automated

pipetting techniques process. (n=10)

圖4:採用手動和自動移液技術的過程的移液準確度.(N=10)

The last experiment was designed to evaluate the

ADP performance when taking the aliquot from the dSPE cleanup vial and

transferring the aliquot to a final extract vial. A 4 mL aliquot was pipetted

using the ADP and transferred to the final extract storage vial.(Table 5)

最後一個實驗是設計用來評估ADP 從dSPE淨化小瓶吸取分裝等分以移轉到最終萃取瓶的性能.吸取4毫升分裝等分及移轉到最終萃取小瓶.(表5)

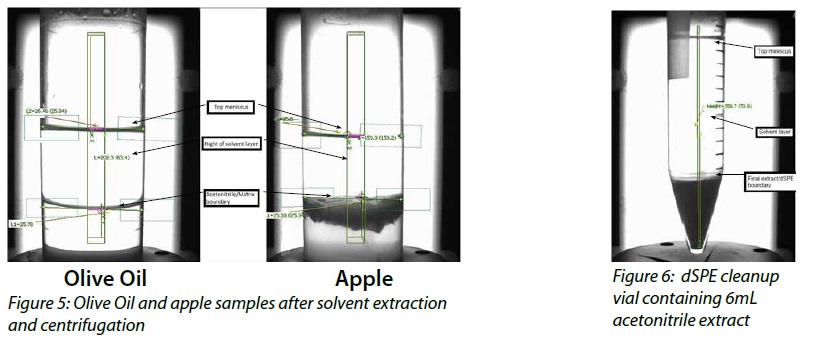

Liquid Level Sensing

液位感測

Automated pipetting can be a challenge when pipetting a limited amount of

extraction solvent from a vial without disturbing a secondary layer within.

當要從小瓶中吸取限量的萃取溶劑,

且不擾動其中的第二層時,

自動移液可以是一個挑戰.

Tekmar has overcome this obstacle through the use of VialVision, a system

that can determine the position of the layers in the vial and calculate the

available volume of the extraction.

Tekmar已經經由VialVision的使用克服了這個障礙. VialVision

是一個可以確定液層在小瓶中的位置, 並計算可取得的萃取液容積的系統.

The volume of the solvent layer can be determine to within 5% accuracy.

Based on these measurements, the system then warns the user if the aliquot to be

taken from the vial exceeds the volume of solvent available.溶劑層的體積可以在5%的精度內被確定. 根據這些測量結果, 系統會警告使用者,

如果要從小瓶取出的等分試樣超過可取得溶劑的體積.

Below are images captured by the VialVison system

of QuEChERS extracts after centrifugation.(Figure 5) Both samples are in 50 mL

conical centrifuge tubes, one sample is an olive oil matrix and the other is an

apple matrix.

下面是QuEChERS的萃取液離心分離後由VialVison系統所捕獲的圖像(圖5).

這兩種樣品均在50毫升錐形離心管中,一個樣品是橄欖油基質,另一個是一個蘋果基質。

Figure 6 is an image of the final extract after

dSPE cleanup and centrifuging.

圖6為dSPE淨化和離心後的最終萃取的圖像.

Conclusions

結論

This study demonstrates the feasibility of automating the QuEChERS

extraction using the AutoMate-Q40.

這項研究說明了採用AutoMate-Q40

進行QuEChERS萃取的自動化的可行性.

By automating the liquid handling, addition of salt/buffers, sample

mixing, pipetting, and liquid level sensing using the patent pending VialVision,

the extraction process is fast, easy and offers time and labor savings, while

improving consistency and repeatability of the extraction.

經由液體處理, 加鹽/緩衝液,樣品混合,移液的自動化,以及使用專利申請中的VialVision液位檢測,萃取過程是快速的,簡便的,並提供了時間和勞力的節省,同時增進了萃取的一致性和可重複性.

References

參考

1. European Committee for Standardization/Technical Committee CEN/TC275

(2008), Foods of plant origin:

Determination of pesticide residues using GC-MS and/or LC-MS/MS following

acetonitrile extraction/partitioning and cleanup by dispersive SPE

QuEChERS-method.

2. AOCA Official Method 2007.07 Pesticide Residues in Food by Acetonitrile

Extraction and Partitioning with Magnesium Sulfate. Gas Chromatography/Mass

Spectrometry and Liquid Chromatography/Tandem Mass Spectrometry, First Action

2007

3. M. Anastassiades: QuEChERS a mini-multiresidue method for the analysis

of pesticide residues in low-fat products