|

|

在層析的領域裏, 模擬移動床(SMB)技術是高性能液相層析的一個變異體.它是用來分離一些用其他方法很難或是不可能解開的粒子或化合物.

傳統上,SMB技術用在油及能源工業中, 它已經非常重要地商業化到油工業.接著, 在食品工業方面, SMB技術以分離糖蜜中的果糖及葡萄糖為起劃下重要的標記. 在此之後(1990年代SMB層析技術已逐漸增加其在活性藥物成份(APIs) 的純化及回收等的普及程度.

近年來, 隨著層析的核心及週邊技術不斷地提升, SMB技術也有了一些重要創新發展. 包括:

1.結合超臨界流體層析(SFC)與模擬移動床(SMB)的SFC-SMB技術.

2.多分離管逆流溶劑梯度純化(MCSGP)技術等.

我們(ABDC)基於近20年的 HPLC/GPC軟硬體的研發經驗,

與本地,大陸,日本及歐美等最有規模及經驗的SMB技術核心及週邊技術研發生產工廠及技術服務團隊均能密切溝通合作.

使我們在 製備型液相層析儀(Process-Preparative HPLC),DNA 合成儀(DNA Synthesisizer),

動態軸向壓縮製備充填(DAC Packing), 模擬移動床層析系統(SMB), 多分離管逆流溶劑梯度純化技術(MCSGP), 超臨界流體層析(SFC),

以及超臨界流體模擬移動床層析系統(SFC-SMB) 等互為基礎及應用技術項目, 有特別完整的整合應用服務的能力.

除了column填料以外, SMB及SFC的核心關鍵零組件在於精密的製備型HPLC PUMP及製備型層析管 ,

而週邊的電控閥件及控制軟硬體則為必須的輔助條件. 這些, ABDC均有良好的, 全球規模級的協力廠商, 以及完全自主能力的控制軟硬體客製化研發能力.

我們同時結合本地,大陸,日本及歐美等的專業團隊, 我們能為您研發製造完整體系的Process-Preparative HPLC, DNA 合成儀,

DAC, SMB, MCSGP, SFC, 以及SFC-SMB系統. 功能及耐用度相同或更好, 節省購置及設備及耗材成本1/2--2/3.

我們提供您一般進口廠商所沒有的, 最密切完整的客製化, 系統及週邊整合及發展化能力! 是科技先進大廠及先進實驗室, 建構全自動化的生產及品管檢測,

最有幫助的技術及事業合作伙伴.

歡迎洽詢討論您現階段需求及未來的發展規劃 !

相關技術,包括:

1.模擬移動床(SMB):

http://en.wikipedia.org/wiki/Simulated_moving_bed

2.多分離管逆流溶劑梯度純化(MCSGP)技術:

http://en.wikipedia.org/wiki/Multicolumn_countercurrent_solvent_gradient_purification

3.超臨界流體模擬移動床層析(SFC-SMB)技術.

http://www.greenchemistrygroup.org/pdf/2008/MI1545Johannsen.pdf

http://www.tscfa.org.tw/upload/ecr/54_4_1.pdf

各項相關說明介紹如下:

Simulated moving bed(模擬移動床層析系統)

http://en.wikipedia.org/wiki/Simulated_moving_bed

http://en.wikipedia.org/wiki/Simulated_moving_bed

In chromatography,the simulated moving bed (SMB) technique

is a variant of high performance liquid chromatography. It is used to separate

particles and/or chemical compounds that would be difficult or impossible to

resolve otherwise. This increased separation is brought about by a

valve-and-column arrangement that is used to lengthen the stationary phase

indefinitely.

在層析的領域裏, 模擬移動床(SMB)技術是高性能液相層析的一個變異體.

它是用來分離一些用其他方法很難或是不可能解開的粒子或化合物. 這增加的分離能力是由一種用來無限延長固定相的長度的切換閥及分離管的排列所帶來的.

In the moving bed technique of preparative chromatography the feed entry and

the analyte recovery are simultaneous and continuous, but because of practical

difficulties with a continuously moving bed, simulated moving bed technique was

purposed.

在製備型層析的移動床技術中, 進料及分離產物的回收是同時且連續的, 但由於連續移動床實際上有各種困難,模擬移動床技術於是成為實際的目標.

In the simulated moving bed technique instead of moving the bed, the sample

inlet and the analyte exit positions are moved continuously, giving the

impression of a moving bed.[1] in [2]

在模擬移動床技術中, 並不是去實際移動分離固定相床體, 而是連續地移動樣品進入口及分離產物的出口位置, 產生一個移動中的分離固定相床體的印像.

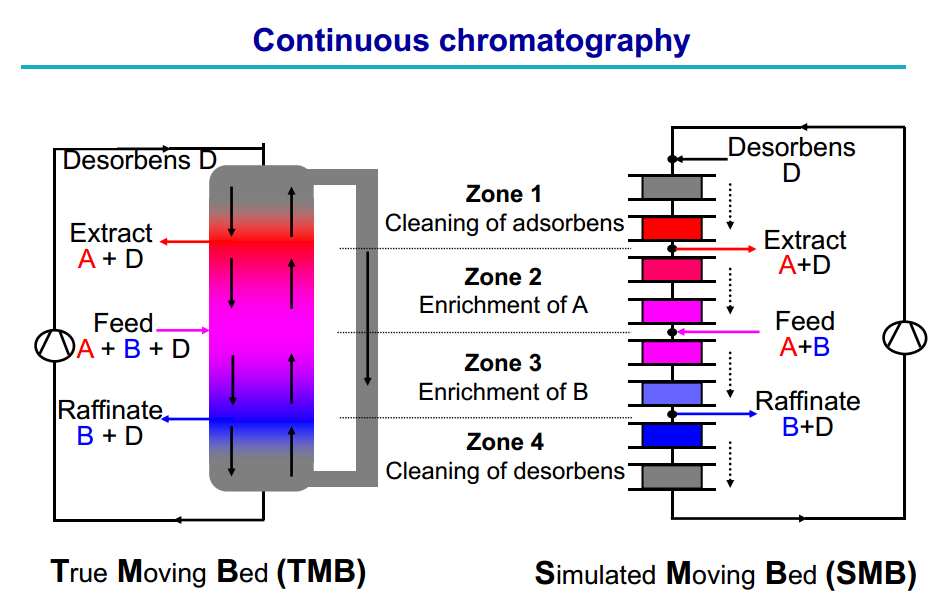

True moving bed chromatography (TMBC) is only a theoretical concept. Its

simulation, SMBC is achieved by the use of a multiplicity of columns in series

and a complex valve arrangement, which provides for sample and solvent feed, and

also analyte and waste takeoff at appropriate locations of any column, whereby

it allows switching at regular intervals the sample entry in one direction, the

solvent entry in the opposite direction, whilst changing the analyte and waste

takeoff positions appropriately as well.[3]

真實移動床層析(TMBC)只是一個理論上的觀念. 它的模擬, 也就是模擬移動床層析(SMBC)是由一個序列連接的多支分離管以及複雜的切換閥來達到的.

這些閥及分離管用於在任何分離管的適當位置進行樣品及溶劑的進料,以及分離產物及廢料的取出,

因此能夠以規律的間格在一個方向切換樣品的進入點,在相反的方向切換溶劑的進入點, 而適當地改變分離產物及廢液取出口的位置也是一樣的.

Ref 3 explains that the advantage of the SMBC is high speed, because a system

could be near continuous, whilst its disadvantage is that it only separates

binary mixtures. It does not say, but perhaps it can be assumed that this is

equivalent with the separation of a single component from a group of compounds.

With regard to efficiency it compares with simple chromatography technique like

continuous distillation does with batch distillation.

參考來源[3]說明了模擬移動床層析(SMBC)的優點是速度很快,因為它是接近於連續的系統, 但也因此只能分離二元的混合物. 雖然不能這樣說,

但或許它可以被設想成說是相當於從一群化合物中分離出一個單一的成份. 在關於其與一般層析技術的效率比較方面,就像是連續蒸餾與批次蒸餾的比較.

Contents(內容) 1.

Construction(建構)

Specifically, an SMB system has two or more identical columns, which are

connected to the mobile phase pump, and each other, by a multi-port valve. The

plumbing is configured in such a way that:

a) all columns will be connected in series, regardless of the valve's

position;

b) each different position of the valve will reconnect the columns to one

another in one possible sequential arrangement of the columns; and

c) all possible positions of the valve will arrange the columns in every

possible sequential order. For example, consider a case where two HPLC columns,

A and B, are connected to one another, and the mobile-phase pump, via a

six-port, two-position valve (e.g. a Rheodyne 7000).

特別的是,一個模擬移動床系統(SMB)有兩支和更多支的分離管, 以多孔位閥連接到移動相的PUMP,以及互相連接. 管路的連接組態方式是:

(a)不管閥的位置如何, 所有的分離管是以序列連接.

(b)閥的每個不同的位置的設定,將以一種可能存在的順序,重新連接這組分離管.

(c)所有閥的可能的不同位置的設定,將排列出這組分離管的美一個可能存在的順序. 例如說,考慮有2支HPLC分離管互相連接的情況,

包括其移動PUMP,經由一個六通閥及2位置切換閥(例如,Rheodyne 7000)

One valve position will distribute the flow in the manner

Pump-->Column A-->Column B-->Waste,

while the other position will distribute the flow in the manner

Pump-->Column B-->Column A-->Waste.

Consequently, switching of the valve will "leapfrog" the columns over

one another.

If elution across two columns in series is not adequate to resolve two

compounds in a given run, the eluent can then be made to go through 3, 4, 5...

columns in additional runs by carefully timed switching. This increases the

number of theoretical plates until separation can be attained.

採用其中一個閥的位置後, 其流通方式為: PUMP -> A分離管 -> B分離管 -> 廢液.

而切換到另一個閥的位置後, 其流通方式為: PUMP -> B分離管 -> A分離管 -> 廢液.

其結果就是,閥位置的切換直接成為2個分離管在流路位置的"跳蛙式”變換.

假如在這2個串接的分離管作沖滌仍然不足以在一個程序中分離2個化合物,

那麼就可以讓沖滌液,以小心的時間切換方式,在增加的程序中,通過串接的第3,4,5個分離管. 這樣可以增加理論板數值,直到得出所須分離的效果.

Advantages(優點)

When affinity differences between molecules are very small, it is sometimes

not possible to improve resolution via mobile- or stationary-phase changes. In

these cases, the multi-pass approach of SMB can separate mixtures of those

compounds by allowing their small retention time differences to accumulate.

當不同的分子之間的親和力很小時, 有時很難經由改變移動相或固定相來增進解度. 在這些情況下,

這種SMB的多次通過的方法就能夠藉由累積小量的滯流時間差來分離這些化合物.

At industrial scale an SMB chromatographic separator is operated

continuously, requiring less resin and less solvent than batch chromatography.

The continuous operation facilitates operation control and integration into

production plants. Low eluent comsumption High product concentration High

productivity Continuous process .

在工業化的規模時, 模擬移動床(SMB)層析分離設備是連續操作的,比起批次層析,需要更少的樹酯及更少的溶劑. 此連續操作的特性,

使其操作控制及整合建構能進到製造工廠裏.

Drawbacks(缺點)

The drawbacks of the SMB are higher investment cost compared to single column

operations, a higher complexity, as well as higher maintenance costs. But

these drawbacks are effectively compensated by the better yield and a much lower

solvent consumption as well as a much higher productivity compared to simple

batch separations.

For purifications, in particular the isolation of an intermediate single

component or a fraction out of a multicomponent mixture, the SMB is not suited

in general. It can only separate two fractions from each other and it does not

implement linear solvent gradients as required for the purification of

biomolecules.

與單分離管操作來比較, 模擬移動床(SMB)的缺點是比較高的投入成本, 比較複雜以及同樣較高的維護成本.

但是這些缺點可以很有效地被比較好的產出率,比較低很多的溶劑消耗以及很高的產能所補償了.

不過對於純化方面, 特別是中間體單一成份或多成份混合物的一部份, SMB般說來是不適合的. 它只能在兩種成份之間進行分離,

而且它不使用如在生物分子的純化的線性溶劑梯度.

Applications(應用)

In size exclusion chromatography, where the separation process is

driven by entropy, it is not possible to increase the resolution attained by a

column via temperature or solvent gradients. Consequently, these separations

often require SMB, to create usable retention time differences between the

molecules or particles being resolved.

SMB is also very useful in the pharmaceutical industry, where

resolution of molecules having different chirality must be done on a very large

scale.

For the production of Fructose e.g. in High fructose corn syrup or

amino-acids, biological-acids, etc. industrial scale chromatography is used.

在斥濾層析(SEC-GPC/GFC)裏,分離程序是由物質的熵來驅動的, 它是不可能經由溫度或溶劑梯度來增加分離解析度的. 因此,

其分離經常需用到SMB,以能夠在要被解析的分子或粒子之間創造出有用的滯留時間差.

SMB 在製藥工業也非常有用, 這裏具有對掌性差異的分子的解析必需要大規模地進行.

從高果糖玉米糖漿或氨基酸, 生物酸等生產果糖等, 需用到工業規模的層析法.

Orochem Technologies Inc, a Chicago-based chemical technology company has

advanced the application of SMB for the purification of a variety of different

molecules like omega-3 fatty acids, sugars, biofuels and APIs.[4]

Orochem Technologies 公司, 一家以Chicago為基礎的化學科技公司,

已經進一步將SMB應用於一些各種分子的純化,像omega-3脂肪酸,糖, 生質燃料以及API(Active pharmaceutical

intermediate molecules.

Multicolumn countercurrent solvent gradient

purification

(多分離管逆流溶劑梯度純化)

http://en.wikipedia.org/wiki/Multicolumn_countercurrent_solvent_gradient_purification

http://en.wikipedia.org/wiki/Multicolumn_countercurrent_solvent_gradient_purification

Multicolumn Countercurrent Solvent Gradient Purification

(MCSGP) is a form of chromatography that is used to separate or purify

biomolecules from complex mixtures. It was developed at the Swiss Federal

Institute of Technology Zurich by Aumann and Morbidelli.[1]

The process consists of two to six chromatographic

columns which are connected to one another in such a way that as the mixture

moves through the columns the compound is purified into several fractions.

多分離管逆流溶劑梯度純化(MCSGP)是一種用於從複雜的混合物中分離及純化生物分子的層析的型態.

它是在瑞士蘇黎世聯邦科技學院的Aumann and Morbidelli所發展出來的.

這種程序由2-6支分離管層析分離管所組成, 這些分離管連接的方式是使混合物通過這些分離管,

而化合物則是被純化到幾個部份.

Contents(內容):

Overview(綜覽)

The MCSGP process consists of several chromatographic columns which are

switched in position opposite to the flow direction. Most of the columns are

equipped with a gradient pump to adjust the modifier concentration at the column

inlet. Some columns are connected directly, so that non pure product streams are

internally recycled.

Other columns are short circuited, so that they operate in pure batch mode.

MCSGP程序由數支分離管層析分離管所組成,過閥門的切換, 以與流體流動的相反方向來變換這些分離管串接位置.

大部份的分離管都配備有梯度PUMP以調節分離管入口的修飾劑的濃度. 某些分離管是直接連接的, 使不純的產物串流可以在內部循環.

其他分離管是走捷徑連接的,使其能以單純的批次模式來操作.

The system is split into several sections, from which every section performs a

tasks analog to the tasks of a batch purification. These tasks are loading the

feed, running the gradient elution, recycling of weakly adsorbing site

fractions, fractionation of the purified product, recycling of strongly

adsorbing site fractions, cleaning the column from strongly adsorbing

impurities, cleaning in place and re-equilibration of the column to start the

next purification run.

All of the tasks mentioned here are carried out at the same time in one unit.

Recycling of non pure site fractions is performed in countercurrent movement.

The fully continuous process consists of at least 6 columns. Semi-continuous

operation with only 3 columns shows the same performance and it can even have a

higher productivity.

此系統可分開為幾個區段, 每一區段表現出類同於批次純化的各項任務. 這些任務有進料載入, 梯度的進行,

弱吸附節點的餾份的回流,純化產物的分餾,強吸附節點的餾份的回流分離管中強吸附雜質的洗清, 原位置做分離管洗清及再平衡以進行下一回的純化程序.

所有提到的這些任務是在一個單元裏同時進行. 不純節點餾份的回流是以逆流方向進行.

完整的程序至少由6支分離管組成. 由3支分離管組成的半連續的操作表現出相同的性能,甚至有更高些的產出.

Comparison with other purification methods

(與其他純化方法的比較)

Biomolecules are often purified via solvent gradient batch chromatography. Here

smooth linear solvent gradients are applied to carefully handle the separation

between the desired component and hundreds of impurities.

The desired product is usually intermediate between weakly and strongly

absorbing impurities. A center cut is required to get the desired pure product.

Often the preparative resins have a low efficiency due to strong axial

dispersion and slow mass transfer. Then a purification in one chromatographic

step is not possible. Countercurrent movement as known from the SMB process

would be required.

生物分子經常是經由溶劑梯度的批次層析來進行純化的. 在這樣的方式下,使用平順的溶劑梯度,小心的處理在所要的成份與數佰種雜質之間的分離.

所要的產物通常是介於弱的及強的吸附不純物的中間. 一個中心切割是需要用以得出所要的產物的.

通常製被型的樹脂由於有軸向強分散性,以及低的質量轉移, 所以, 要在一個層析步驟中做純話是不可能的. 因而,

SMB的逆流移動程序就成為所需要的方法.

For large scale productions and for very valuable molecules countercurrent solid

movement need to be applied to increase the separation efficiency, the yield and

the productivity of the purification. The MCSGP process combines both techniques

in one process, the countercurrent SMB principle and the solvent gradient batch

technique.

對於非常有價值的分子的大規模生產, 需採用逆流的固態移動, 以增加純化的分離效率,產率及產量. MCSGP

程序把這兩種技術結合在一個程序中, 即逆流SMB原理及溶劑梯度批次技術.

Discontinuous mode consists of equilibration, loading, washing, purification and

regeneration steps. The discontinuous mode of operation allows exploiting the

advantage of solvent gradients, but it implies high solvent consumptions and low

productivities with respect to continuous countercurrent processes.

An established process of this kind is the simulated moving bed technique (SMB)

that requires the solvent-consuming steps of equilibration, washing,

regeneration only once per operation and has a better resin utilization.

However, major drawbacks of SMB are the inability of separating a mixture into

three fractions and the lack of solvent gradient applicability.

非連續模式是由平衡, 載入, 清洗, 純化及再生等步驟所組成. 非連續操作模式允許能發揮溶劑梯度的優點, 但相對於連續逆流程序來說,指的就是高溶劑消耗及低產量.

一種已經建立的這種程序是以模擬移動床(SMB)方式建立的, 它在每一回操作只需要做一次的平衡, 清洗, 再生等溶劑消耗步驟.

但不論如何, SMB的主要缺點是它沒辦法把混合物分開成3個餾份, 也缺乏溶劑梯度的應用能力.

In the case of antibodies, the state-of-the-art technique is based on batch

affinity chromatography (with Protein A or Protein G as ligands) which is able

to selectively bind antibody molecules. In general, affinity techniques have the

advantage of purifying biomolecules with high yields and purities but the

disadvantages are in general the high stationary phase cost, ligand leaching and

reduced cleanability.

在抗體方面, 最先進的技術是基於批次的親和層析以 Protein A or Protein G為配體), 它能購選擇性地連結抗體分子.

一般來說,親和層析在純化生物分子方面,具有高產率及純度的優點, 但一般來說,也有高固定相成本, 配體淋溶,以及逐漸降低的可清洗能力.

The MCSGP process can result in purities and yields comparable to those of

purification using Protein A. The second application example for the MCSGP

prototype is the separation of three MAb variants using a preparative weak

cation-exchange resin. Although the intermediately eluting MAb variant can only

be obtained with 80% purity at recoveries close to zero in a batch

chromatographic process, the MCSGP process can provide 90% purity at 93% yield.

A numerical comparison of the MCSGP process with the batch chromatographic

process, and a batch chromatographic process including ideal recycling, has been

performed using an industrial polypeptide purification as the model system. It

shows that the MCSGP process can increase the productivity by a factor of 10 and

reduce the solvent requirement by 90%.[2]

用Protein A, MCSGP程序能達到與這些純化可相比較的純度及產率.

第二個MCSGP雛型的應用力例子是用一種製備用的弱陽離子交換樹脂來分離3個MAb的變體.

雖然在一個批次層析程序裏,直接沖滌出來的MAb變體整只能有80%的產率, 回收率接進於零, MCSGP程序能在93%產率下,能提供90%的純度.

一個MCSGP程序與批次層析程,以及與具有理想回流的批次層析程序的數據比較,已經以工業的多肽純化模型系統呈現出來.

它顯示MCSGP程序能增加10倍的產能及減少90%的溶劑需求.

The main advantages with respect to solvent gradient batch chromatography are

high yields also for difficult separations, less solvent consumption, higher

productivity, usage of countercurrent solid movement, which increases the

separation efficiency. The process is continuous. Once a steady state is

reached, it delivers continuously purified product in constant quality and

quantity. Automatic cleaning in place is integrated. A pure empirical design of

the operating conditions from a single solvent gradient batch chromatogram is

possible.

相對與於溶劑梯度的批次層析程序, 主要的優點有: 對於難分離的情況也有高的產率, 少的溶劑消耗, 較高的產量, 以及使用能增加分離效率的逆流固相移動等.

Applications(應用)

All chromatographic purifications and separations which are executed via solvent

gradient batch chromatography can be performed using MCSGP.

Typical examples are reversed phase purification of peptides, hydrophobic

interaction chromatography or for example ion exchange chromatography of

proteins or antibodies.

The process can effectively enrich components, which have been fed in only small

amounts. Continuous capturing of antibodies without affinity chromatography can

be realized with the MCSGP-process.[3]

所有經由進行溶劑梯度的批次層析的純化與分離都能用MCSGP方法呈現.

典型的例子有逆相的肽的純化, 蛋白質或抗體的疏水性交互作用層析或離子交換層析.

此程序能有效地富集這些進料當中只有少量的各個成份. 可以用MCSGP程序來達成不用親合層析法的抗體連續捕集.

Simulated moving bed chromatography overview &

Applications.

(模擬移動床層析綜覽與應用)

http://orochem.com/index.php?route=information/information&path=3_17&information_id=61

http://orochem.com/index.php?route=information/information&path=3_17&information_id=61

Overview(綜覽)

SMB(Simulated Moving Bed) Background(SMB(模擬移動床)背景)

Simulated moving bed (SMB) technology is a

chromatography technique that is traditionally used in oil and energy industry

for recovery and purification of p-xylene and other aromatic components

separated from naphtha feed.

After it became commercialized heavily into the oil

industry, SMB technology made its mark on the food industry by separating

fructose from glucose in a molasses feed.

Since then (1990s), SMB chromatography has become

increasingly popular with biotechnology companies for purification and recovery

of active pharmaceutical intermediates (APIs).

模擬移動床(SMB)技術是種層析的技術,傳統地在油及能源工業中,用於回收及純化從石腦油進料分離出來的對二甲苯及其它芳香族的成份.

在它已經非常重要地商業化到油工業中之後, SMB技術以分離糖蜜中的果糖及葡萄糖,

劃下了它在食品工業的標記.

從此(1990s),

SMB層析技術已逐漸增加其在生物科技公司對於活性藥物成份(APIs)的純化及回收等普及的程度.

Several examples of processes established in industry include the SORBEXR

process as well as the PAREXR, and AromaxR for recovery of p-xylene from C-8

isomer mixtures both commercialized by UOP(Universal Oil Products Co.).

Other examples of SMB processes commercialized (also from UOP) include EbexR for

the separation of ethylbenzene from a mixture of C-8 aromatic isomers, MolexR

for the separation of n-parafin’s from branched and cyclic hydrocarbons, and

OlexR for the separation of olefins from parafins.

Other examples in the chemical industry are CresexR and CymexR for the

separation of p-cresol and p-cymene from its isomers and SarexR.

在工業上所建立的幾個程序的例子包括SORBEXR程序及PAREXR程序, 以及用於從C-8異構混合物回收對二甲苯的AromaxR 程序,

兩者都也由UOP公司商業化了.

其他商業化的SMB程序(也由UOP公司)包括用於從C-8芳香異構混合物分離苯乙烯的ethylbenzene的EbexR 程序,

用於從分枝及環狀碳水化合物分離正-石臘的MolexR 程序,以及從石臘中分離烯烴的OlexR程序.

其他化學工業的例子有從其異構混合物分離出對甲酚和對甲基異丙基苯的CresexR and CymexR程序及SarexR程序.

To understand and utilize the SMB technology, it is imperative to study

techniques of batch or column chromatography. All research and development

efforts to operate an SMB are focused on column chromatography studies.

Once components in a material are able to be separated at reasonable capacity

with respect to a certain mobile phase, stationary phase, and feed flow rate,a

scale up to SMB is possible.

Column chromatography, at any scale, is not practical to use for large scale

production and purification of molecules. Compared to SMB technology, in column

chromatography, the stationary phase is not utilized efficiently. This is

because the separation zone between the components decreases during a column

chromatography separation.

要瞭解及應用SMB技術, 就必須研究批次或分離管層析. 在操作SMB的所有研究及發展的努力是集中在分離管層析的研究上.

當一種物料的各成份已經能夠以某種移動相,固定相以及進料流率達到一個合理的容積因子時, 將其放大到SMB即是可能的.

分離管層析, 在任何規模下要用於大規模的製造與純化上是不實際的. 與SMB技術比較, 分離管層析的固定相是沒有被有效率的應用.

這是因為在分離管層析分離的過程中,成份之間的分離帶的是減少的.

In an SMB, the separation zone is large and is maintained at a constant width.

Also, compounds are often unable to be separated in column chromatography

because the column length is usually not long enough.

Overall, in column chromatography, the stationary phase is largely

under-utilized and thus most column separation processes require excess amounts

of solvent to complete a separation between compounds.

One of the major drawbacks of column chromatography is that it is a batch or

linear process which results in the process having to be repeated to achieve a

similar result as continuous SMB process. Thus, a column chromatography

separation is always expensive to scale up as compared to an SMB.

在SMB裏, 分離帶很大,而且維持在一個恆定的寬度. 而且在分離管層析裏, 化合物經常沒法被分開, 因為分離管的長度不足.

總體上, 在分離管層析裏, 固定相很大程度上是處於低應用效率的狀態, 因而大部份的分離管分離程序須要過多的溶劑以完成各化合物之間的分離.

分離管層析的一個主要缺點是它是一種批次或線性的程序, 它的結果是必須反覆進行才能完成像SMB程序的結果.

所以,分離管層析分離要放大到與SMB相比較的規模永遠都是很昂貴的.

Moving Bed Principle(移動床原理)

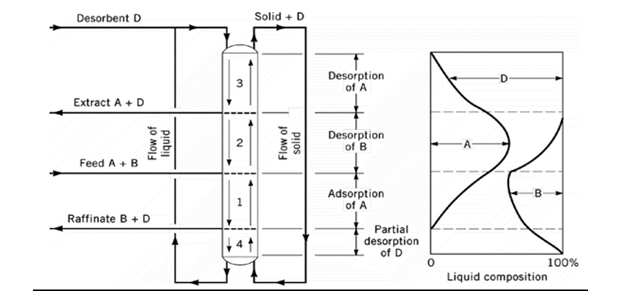

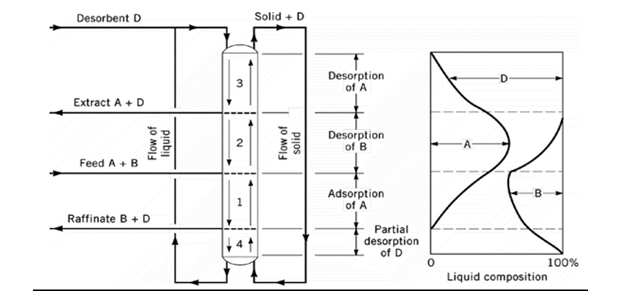

A hypothetical moving bed system and a liquid phase composition profile are

shown in Figure 1. The adsorbent circulates continuously as a dense bed in a

closed cycle and moves up the adsorbent chamber from bottom to top. Liquid

streams flow down through the bed counter-currently to the solid. The feed is

assumed to be a binary mixture of A and B, with component A being adsorbed

selectively. Feed is introduced to the bed as shown.

圖一表示出來的是一個設想的移動床以及液相組成的剖析. 吸附劑以濃稠的床體的形態在一個封閉循環中連續流動, 在吸附室中由底部往頂部向上移動.

液流逆流於固體方式向下流經床體. 進料假設是A及B二元成份的混合體, 其中A成份被選擇性地吸附.

Desorbent D is introduced to the bed at a higher level. This desorbent is a

liquid of different boiling point from the feed components and can displace feed

components from the pores. Conversely, feed components can displace desorbent

from the pores with proper adjustment of relative flow rates of solid and

liquid. Raffinate product, consisting of the less strongly adsorbed component B

mixed with desorbent, is withdrawn from a position below the feed entry.

去吸附劑D從較高的位置引進到床體. 去吸附劑是一種與進料成份沸點不同的液體,而且可以從孔粒中取代進料成份. 相反地,

進料成份能經由固體及液體相對流率的適當調整, 從孔粒中取代去吸附劑成份. 雜餘物是由較未被強力吸附的成份B與去吸附劑混合所組成. 餘料是由低於進料入口處取出.

Only a portion of the liquid flowing in the bed is withdrawn at this point; the

remainder continues to flow into the next section of the bed. Extract product,

consisting of the more strongly adsorbed component A mixed with desorbent, is

withdrawn from the bed; again, only a portion of the flowing liquid in the bed

is withdrawn, and the remainder continues to flow into the next bed section.

只有一部份在床體中流動的液體在這一為置點被取出來, 剩下的繼續流到床體的下一個區段. 萃取產物, 由被強力吸附的成份A與去吸附劑混合所組成, 也被由床體取出,

一樣地, 只有一部份在床體中流動的液體被取出來,其餘的繼續流到床體的下一個區段.

The positions of introduction and withdrawal of net streams divide the bed into

four zones, each of which performs a different function as described below. Zone

1. The primary function of this zone is to adsorb A from the liquid. Zone 2. The

primary function of this zone is to remove B from the pores of the solid Zone 3.

The function of this zone is to desorb A from the pores Zone 4. The purpose of

this zone is to act as a buffer to prevent component B, which is at the bottom

of Zone 1, from passing into Zone 3, where it would contaminate extracted

component A.

液流的淨流動的導入及取出位置, 將床體分為4個區帶, 每各區帶以下列描述的不同功能呈現出來. 區帶1.這區帶主要的功能是從液流中吸附A.

區帶2.這區帶主要的功能是從固體孔粒中移除B. 區帶3.這區帶的功能是從固體孔粒中去除A的吸附.

區帶4.這區帶的目的是作為緩衝,以防止在區帶1底部的成份進到區帶3, 以避免污染了要被取出的成份A.

Simulated Moving Bed Operation(模擬移動床的操作)

In the moving bed system of Figure 1, solid is moving continuously in a closed

circuit past fixed points of introduction and withdrawal of liquid. The same

results can be obtained by holding the bed stationary and periodically moving

the positions at which the various streams enter and leave. A shift in the

positions of the introduction of the liquid feed and the withdrawal in the

direction of fluid flow through the bed simulate the movement of solid in the

opposite direction. Of course, moving the liquid feed and withdrawal positions

continuously is impractical.

在圖一的移動床系統中,固體在一個封閉路線中,經過固定的導入及取出點, 連續地移動. 同樣的結果可以經由固定床體不動以及移動不同液體串流的進出位置來得到.

以液流通過床體的方向來移動液體進料的引入及取出的位置,模擬出固體在相反方向的運動. 當然,連續地移動液體的進入及取出為至置是不實際的.

However, approximately the same effect can be produced by providing multiple

liquid access lines to the bed and periodically switching each stream to the

adjacent line. Functionally, the adsorbent bed has no top or bottom and is

equivalent to an annular bed. Therefore, the four liquid access positions can be

moved around the bed continually, always maintaining the same distance between

the various streams.

無論如何? 可以用多個連接到床體的液流存取管線,以及週期性地切換每個流體到相鄰的管線的方式來製造出大約相同的效果.

功能上,吸附床沒有頂部或底部之分,即相當於是環狀的床體. 因此, 這4個液流存取位置能被延著床體連序地移動,而總是在各液流之間保持相同的距離.

The commercial application of this concept is portrayed in Figure 2, which shows

the adsorbent as a stationary bed. A liquid circulating pump is provided

to pump liquid from the bottom outlet to the top inlet of the adsorbent chamber.

A fluid directing device known as a rotary valve is provided.

這個關念的商業化應用描繪在圖2中, 圖2.顯示出吸附劑為固定的床體. 一個液體循環PUMP用來把流體由吸附室的底部的出口輸送到吸附室的頂部的入口.

使用的一個流體導向的設備為已知的旋轉閥.

The rotary valve functions on the same principle as a multi-port stopcock in

directing each of several streams to different lines. At the right hand face of

the valve, the four streams to and from the process is continuously fed and

withdrawn. At the left hand face of the valve, a number of lines are connected

that terminate in distributors within the adsorbent bed.

The rotary valve is the most widely used method in industrial scale applications

for accomplishing the stepwise movement of external streams from bed to bed.

This same function can be accomplished using manifolds of on-off valves.

For a 24-bed process application, more than 100 such valves could be required.

Small scale SMB applications, such as for chiral separations, make extensive use

of switching valves.

在導向幾個液流的每一個到不同的管線時,旋轉閥以相同於多端口活塞一樣的功能運作. 在閥右手面,

由這個程序進出的這4個液流是連續地在做進料及取出. 在閥左手面, 連接有一定數量的管線, 用於終止吸附床體內的分配.

在達成床體之間外部液流逐步移動的工業化規模應用上, 旋轉閥是最廣為使用的方法. 同樣的功能也能用開關閥組成的歧管來達成.

對於一個24床的程序應用,100個以上的閥可能是需要的.

小規模的SMB應用, 例如對掌異構物的分離,切換閥的使用很多.

At any particular moment, only four lines from the rotary valve to the adsorbent

chamber are active. Figure 2 shows the flows at a time when lines 2, 5, 9, and

12 are active. When the rotating element of the rotary valve is moved to its

next position, each net flow is transferred to the adjacent line; thus,

desorbent enters line 3 instead of line 2, extract is drawn from 6 instead of 5,

feed enters 10 instead of 9, and raffinate is drawn from 1 instead of 12.

在任何特定時刻,只有4條由旋轉閥到吸附室的管線是有作用的. 圖二顯示在一個時間裏的流向, 此時管線 2, 5, 9,及12是有作用的.

當旋轉閥的旋轉元件轉到它的下一個位置, 每一個流體串就被轉移到臨近的管路中, 如此, 吸附劑進入了管路3而不是管路2, 萃取物則是由管路6取出而不是管路5,

進料則是由管路10進入而不是管路9, 餘料則是由管路1取出而不是管路12.

Figure 1 shows that in the moving bed operation, the liquid flow rate in each of

the four zones is different because of the addition or withdrawal of the various

streams.

In the simulated moving bed of Figure 2, the liquid flow rate is controlled by

the circulating pump. At the position shown in Figure 2, the pump is between the

raffinate and desorbent ports, and therefore should be pumping at a rate

appropriate for Zone 4. However, after the next switch in position of the rotary

valve, the pump is between the feed and raffinate ports, and should therefore be

pumping at a rate appropriate for Zone 1.

圖二顯示在流動床操作裏, 因為各液流的加入及取出, 在每個區帶內的液體流率是不同的. 在圖二的模擬移動床中,液體流率是由循環PUMP來控制.

在圖二顯示的位置, PUMP 是位於餘料及去吸附劑的端口之間, 因而應以適於區帶4的速率輸送. 而在旋轉閥切換到它的下一個位置之後, PUMP

是位於進料及餘料的端口之間, 因而應以適於區帶1的速率輸送.

Stated briefly, the circulating pump must be programmed to pump at four

different rates. The control point is altered each time an external stream is

transferred from line 12 to line 1.

To complete the simulation, the liquid flow rate relative to the solid must be

the same in both the moving bed and simulated moving bed operations. Because the

solid is physically stationary in the simulated moving bed operation, the liquid

velocity relative to the vessel wall must be higher than in an actual moving bed

operation.

簡要地說, 循環PUMP必須以可程式化為4種不同的輸送速率. 控制點在每一次外部流體由管線12轉移到管線1時被更改了.

要完整地模擬, 則相對於固體的液體的流率在移動床及模擬移動床的操作上必須是相同的.

因為在模擬移動床的裏的固體是靜態實體的,液體相對於容器管壁的速度必須高於實際移動床的操作.

The primary control variable at a fixed feed rate, as in the operation pictured

in Figure 2, is the cycle time, which is measured by the time required for one

complete rotation of the rotary valve (this rotation is the analog of adsorbent

circulation rate in an actual moving bed system), and the liquid flow rate in

Zones 2, 3, and 4.

如圖二的操作圖示, 在進料流速固定時,主要的控制變項是循環時間, 它是經由量測旋轉閥一次完整旋轉所需要的時間

(此旋轉即類在比於實際移動床系統裏的吸附劑循環速率) ,以及在區帶2,3,4 的液體流率.

When these control variables are specified, all other net rates to and from the

bed and the sequence of rates required at the liquid circulating pump are fixed.

An analysis of sequential samples taken at the liquid circulating pump can trace

the composition profile in the entire bed. This profile provides a guide to any

changes in flow rates required to maintain proper performance before any

significant effect on composition of the products has appeared. Various aspects

of process control are described in the patent literature.

當這些控制變項已經被指定了, 其他進出床體的淨速率,以及在液體循環輸送所需要的一系列的流率就被固定下來了.

由液體循環輸送pump處的序列採樣分析, 能追蹤整個床體組成的剖析數據. 這些瓿析數據, 能在出現任何對於產品組成有顯著影響之前,

提供維持正常表現所需要的任何流率改變的指引. 在專利文獻裏有描述程序控制的各面向.

|